Learn about MLCC ceramic capacitors case sizes and their importance in the electronics industry. Understand inch and metric systems and how to mate them.

Key Takeaways

- MLCC Case Sizes are governed by EIA standards, reflecting both Imperial and Metric measurements.

- The Electronic Components Industry Association (ECIA) oversees standards for passive components, stemming from the EIA.

- MLCC sizes range from 008004 to 8060, with specific dimensions but variable height based on application needs.

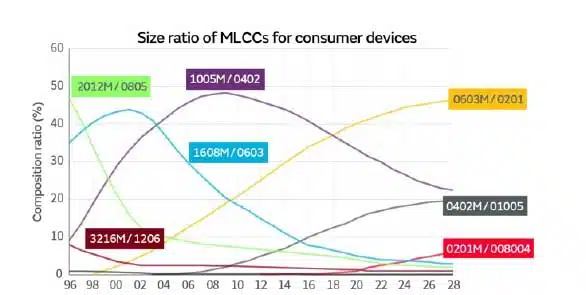

- Over time, industry trends show a demand for smaller MLCC sizes, with 0201 to 1206 being the most popular.

- Design advances aim to minimize size, weight, and power while enhancing functionality in MLCC designs.

Standards are a form of technical infrastructure, and their influence is felt throughout the electronics industry. For example, formed in 1924, the Electronic Industries Alliance (EIA) was an American standards organization that established an alliance of trade associations in the United States electronics manufacturing industry. Their collaboration ensured that electronic equipment produced by different manufacturers was compatible and interchangeable. The EIA formally dissolved in February 2011, dividing by sector.

The Electronic Components, Assemblies, Equipment, and Supplies Association (ECA) continued to develop standards for passive and electromechanical (IP&E) components, overseeing details like direct component marking, data modeling, color-coding, and packaging. All other component standards were expected to be managed by their respective industry sectors. Also in 2011, the ECA merged with the National Electronic Distributors Association (NEDA) to form the Electronic Components Industry Association (ECIA). Today, the ECIA still supports EIA standards development for passive and electromechanical electronic components.

MLCC Case Sizes

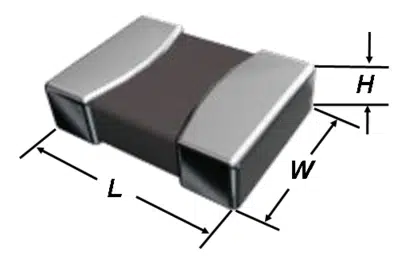

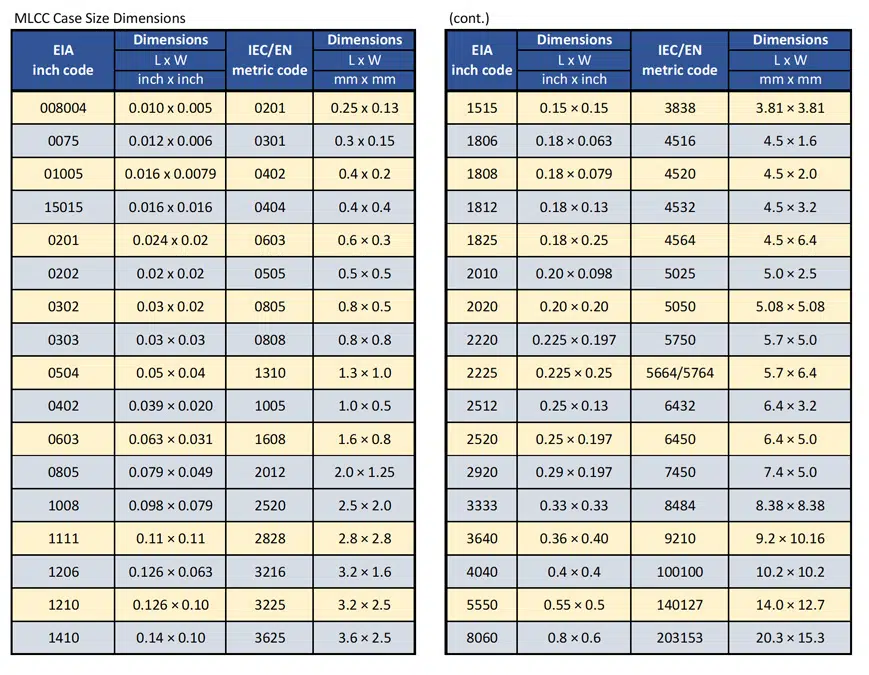

MLCC requirements fall under EIA-198. Their standardized size and shape offerings are a reflection of American EIA standards, often represented using Imperial measurements (e.g., inches) rather than Metric. When reading a specifications chart, like Figure 1, EIA dimension codes correspond with the dimensions of the MLCC itself. For example, a rectangular chip with the dimensions 0.08 inches in length by 0.05 inches in width is coded as “0805.” Looking at the chart, you’ll notice International Electrotechnical Commission/ European Standard (IEC/EN) codes too. The Joint Electron Device Engineering Council (JEDEC) established this set of specifications to represent the Metric system. See Figure 1. below with EIA inch and IEC/EN metric dimension and codes.

MLCC sizes range from 008004 (0.010 inches x 0.005 inches) to 8060 (0.8 inches x 0.6 inches). Height dimensions aren’t provided in this context because height is application specific, as it depends on the number of layers in the MLCC. Layer count is determined by capacitance requirements.

Figure 2. is showing relative MLCC case size comparison of the most common case sizes.

Over time, case sizes continue to run smaller and smaller. Designers are tasked with minimizing SWaP—size, weight, and power—while maintaining or increasing functionality. It’s no surprise that codes 0201 through 1206 were the most requested sizes over the last two decades, according to Paumanok Research. As time goes on, that range will likely shift downwards. It’s worth noting that the industry has seen a gradual increase in production for the 1206 and 1210 case size MLCCs. Figure 3. sourced from Murata is showing evolution of MLCC case size share with time.

Frequently Asked Questions about MLCC Case Sizes

MLCC (Multilayer Ceramic Capacitor) case sizes define the physical dimensions of the capacitor package. They are standardized by EIA (inch-based codes like 0805) and IEC/EN (metric-based codes) to ensure compatibility across manufacturers.

Standards ensure interchangeability, simplify design, and support global supply chains. They allow engineers to select components that fit precise board layouts while maintaining electrical performance.

EIA codes use imperial dimensions (e.g., 0805 = 0.08 x 0.05 inches), while IEC/EN codes use metric equivalents. Both systems describe the same physical sizes but in different units.

The most widely used case sizes are 0201 through 1206. These sizes balance miniaturization with performance and are heavily used in consumer electronics, automotive, and industrial applications.

Over time, MLCCs are trending toward smaller case sizes to reduce size, weight, and power (SWaP) while increasing functionality. However, demand for larger sizes like 1206 and 1210 has also grown for high-capacitance applications.

How to Identify and Select the Right MLCC Case Size

- Understand the Standards

Learn the difference between EIA (inch-based) and IEC/EN (metric-based) codes. For example, an 0805 MLCC measures 0.08 x 0.05 inches.

- Check Your PCB Layout

Match the MLCC footprint to your printed circuit board design. Ensure pad spacing and soldering requirements align with the chosen case size.

- Consider Electrical Requirements

Select a case size that supports the required capacitance and voltage rating. Larger case sizes often allow higher capacitance values.

- Balance Size, Weight, and Power (SWaP)

For compact devices, choose smaller case sizes like 0201 or 0402. For power or automotive applications, larger sizes like 1206 may be more needed but watch for higher vibration sensitivity. Check flexible termination options and reverse geometry types to increase vibration robustness, lower ESL and better power dissipation.