Source: EPCI original article

By Tomas Zednicek Ph.D. European Passive Components Institute.

This article summarizes history, main features and potentials of niobium and niobium based capacitors.

Niobium is a sister metal to tantalum, and shares many chemical characteristics with it, in addition to a few disadvantages and advantages of its own when used as a capacitor dielectric.

Niobium capacitor technology has existed for decades, but its limitation in maximum rated voltage, lower volumetric efficiency, incompatibility with low ESR polymer electrode, limited range and number of vendors keeps this technology as a niche line of tantalum capacitor industry today. On the other hand, there are still some advantaged (such as lower cost, safety and reliability) that worth a closer look and consideration.

Brief History

Capacitor manufacturers have been evaluating niobium material for years every time the tantalum supply situation becomes unstable. Its lower cost base was also evaluated in order to replace low-voltage aluminium electrolytics.

Development of the first niobium capacitors started in former USSR already in 1960’s motivated by shortage of tantalum there [1]. However, at that time, niobium powders were not available in appropriate low impurity, high quality level and the capacitor reliability was inferior to the tantalum capacitors.

Niobium-based material as easier to get and more abundant in nature captured attention by most of the leading tantalum manufacturers especially after the tantalum shortage and supply chain issues around year 2000. Beside niobium metal powder, NbO material has been introduced with metal conductivity level by J.Fife [2] resulting in some advantage for capacitor application properties. Upon the new development and availability of low impurity Niobium/NbO powders within years 2001-2003 companies AVX, EPCOS (tantalum division acquired by Kemet in 2007), Hitachi (bought by Holy Stone in 2009, acquired by Vishay in 2014), Kemet, NEC and Vishay announced some early sampling and pre-production of niobium-based capacitors in 2002. [3],[4],[5].

Figure 1. NMC series of niobium based capacitor structure; source Vishay8

Nevertheless, despite the very optimistic first results, niobium posed some early technical challenges that capacitor makers were struggling to overcome. The obstacles included high dc-leakage current (two to five times worse than for tantalum capacitors), increase of DCL with lifetime and susceptibility to damage by thermal shock during reflow manufacturing process. Low-CV capabilities have also been a problem because of the lack of high grade, high purity capacitor-grade powders at that time.

Tantalum supply chain has consolidated in further years and the urgency for niobium-based capacitor development dropped versus requirements for lower ESR tantalum capacitors with conductive polymer electrodes. In co-incidence, conductive polymer junction to Nb2O5 dielectric is resulting in even higher DCL that practically disqualify its use with niobium-based capacitors. This next technical challenge would require additional development resources to address some basic physics issues related to potential development of polymer niobium-based capacitors. Hence, most of the manufacturers terminated its further development effort, focusing its development power to the other priorities and obsoleted their niobium-based capacitor lines.

Niobium-based capacitors with MnO2 solid electrolyte are still on the market with high reliability versus cost unique value in certain applications. Vishay obsoleted its SMD chip niobium capacitors in 2017 [8] and the major supplier of SMD NbO capacitors today is AVX Corporation [6] that dedicate its product to mainly automotive, aircraft, defence and high safety applications. Axial niobium capacitors are also still made in Russia by company OJSC ELECOND [7] for industrial, defence and high reliable applications.

Niobium-based Capacitor Technology and Features Background

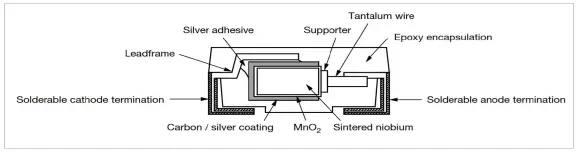

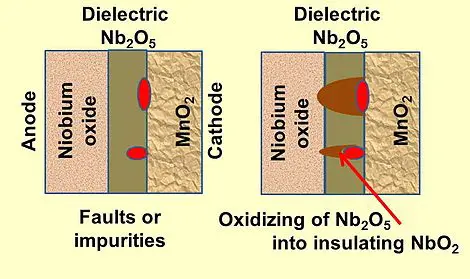

Volumetric efficiency

Niobium, as mentioned, is in many ways behaving very similar to tantalum capacitors. Niobium or NbO material can be processed into a form of powder with a stable oxide Nb2O5 (vs Ta2O5 in case of tantalum) as a high dielectric constant insulation. Niobium pentoxide has a dielectric constant about twice as high as that of tantalum oxide, however the density of niobium is only half that of tantalum, resulting in similar or slightly lower volumetric efficiency compare to tantalum capacitors.

Fig.2. Characteristics of the different tantalum and niobium oxide layers; source: AVX

Abundance

an important advantage of niobium is the abundance of niobium ore in nature relative to tantalum ore; this relative abundance equates to lower cost and better availability within the capacitor marketplace.

Flame Retardant:

Niobium metal is behaving like tantalum capacitors. However, as one of key advantages niobium oxide has a far higher ignition energy than tantalum which results in a significant reduction (up to 95%) of the ignition failure mode of niobium oxide capacitors when compared to conventional tantalum devices.

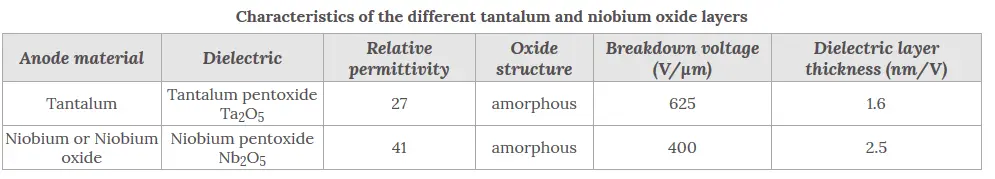

Sub-oxides stability:

One of the “small” differences between niobium and tantalum that makes a big impact to capacitor features is that niobium sub-oxides are stable unlike on tantalum. There are no long term stable suboxides between tantalum and the dielectric tantalum pentoxide (Ta2O5). There are at least two suboxides on niobium-based materials that are stable: NbO and NbO2.

NbO is a material with metallic type of conductivity that can be processed and used as the main anode material same way as Nb or Ta metals (used by NbO capacitors as anode material)

NbO2 is an oxide with semiconductive behaviour that exists together with the “main” dielectric Nb2O5 on the junction with Nb/NbO anode. The NbO2 oxide may grow with temperature (such as during the hot spot in dielectric failure site) and its responsible for the unique “self-arresting” mechanism.

Self-arresting mechanism:

In addition to the self-healing known on conventional tantalum MnO2 capacitors, the NbO capacitors are featuring one more feature when it is exposed to local breakdown, the NbO2 layer on dielectric will grow as a “second” insulation protecting the part to go to short circuit mode. Such part then continues in normal operation even in occasion of the main Nb2O5 dielectric breakdown. Under a specified operating conditions, NbO capacitors are thus one of the safest capacitor technologies on the market.

Fig. 3. Self-arresting mechanism of NbO capacitors; source: Wikiwand

Operating temperature:

Another difference to tantalum capacitors is that Nb2O5 dielectric is more sensitive to higher temperature operation above 85°C. Reliability up to 85°C may be considered as better, about equal at 105°C and inferior at 125°C requiring higher derating compare to tantalum capacitors.

The natural high reliability performance of niobium-based capacitors up to 85°C (including safety margin) makes them suitable for high performance industrial, automotive, defence, medical support, aerospace applications even at safety critical applications.

Rated voltage:

As mentioned, the density of niobium is only half that of tantalum, so twice as much material is needed per unit volume to provide the same charge. The Nb2O5 dielectric constant is higher, but you must form a thicker niobium oxide dielectric for the same voltage. That is good to reduce further the electrical field stress to the dielectric (and achieve better reliability) on one side, but there is a certain limitation in maximum dielectric thickness / maximum rated voltage, driven by powder impurities and formation techniques on the other site. In result, niobium-based capacitors are featuring significantly lower maximum rated voltage compare to tantalum capacitors.

Applications

Where the niobium capacitors bring its benefits:

- High reliability, long term operation, safety circuits, with a “standard ESR requirements” up to 8V application voltage operating in environment up to 85°C safety (105°C qualification) with a little more space on board needed compare to tantalum capacitors (still smaller then aluminium electrolytics). The parts showing high mechanical robustness against shocks and vibrations and stable electrical performance (over MLCC class II capacitors).

There is a wide range of applications were niobium-based capacitors can bring its benefits in low cost for high safety and reliability standards.

applications with benefits from downsizing of aluminium electrolytics capacitor:

- Consumer such as home theatres, game controllers, white goods controllers.

high value in lower cost versus safety and reliability

- Industrial with enhanced safety feature such as smoke detector, security electronics etc

- Automotive such as cabin electronics and telematics

- Aircraft – on board entertainment, telematics, defence (COTS+ version available)

Fig.4. Niobium-based capacitors enhance safety on board of modern civil aircrafts; image source: Boeing

Limitations

Limited sources and product range are the main current limitations of the technology apart of the technical borders discussed above. Case sizes, mounting guidelines etc of the niobium-based chip capacitors are however identical to tantalum and tantalum polymer capacitors, that can be considered as drop-in alternative on the same footprint to avoid single source issues. Thus, the niobium-based capacitors can be considered as additional option where tantalum capacitor designs are considered with enhanced safety feature.

Summary

Niobium-based capacitors present a niche capacitor market share within the tantalum capacitor industry. Nevertheless, some of its unique features, especially high safety, no short circuit failure mode under standard operating conditions and high reliability bring its value to the end users to remain as a viable capacitor solution in longer term future.

The article “Niobium and Niobium Oxide Capacitors Overview” has been published by T.I.C. TANTALUM-NIOBIUM INTERNATIONAL STUDY CENTER’s bulleting No. 177. The pdf version of the bulletin can be downloaded here.

featured image: NbO SMD Capacitor; source: AVX

References

[1] Freeman, Y.; „Tantalum and Niobium-Based Capacitors“; book; Springer ISBN 978-3-319-67869-6;2018

[2] Fife, J.; U.S. Patent 6,391,275 B2

[3] Zednicek,T. Millman,W. Gill;J, “Tantalum and Niobium Technology Roadmap”, AVX, CARTS USA 2002 New Orleans, USA, proceeding

[4] Freeman, Y. & col.,”Niobium Based Solid Electrolytic Capacitors”, Vishay, CARTS USA 2002, New Orleans, Louisiana, USA, proceeding

[5] Zillgen,H. & col., “New Niobium Capacitors with Stable Electrical Parameters”, Epcos, CARTS USA 2002, New Orleans, Louisiana, USA, proceeding

[6] AVX niobium oxide product line http://www.avx.com/products/niobium/

[7] ELECOND niobium product line https://elecond.ru/production/capacitors/niobium/k53-4

[8] Vishay, „Solid Niobium Surface Mount Chip Capacitors“; catalogue 2017; https://www.vishay.com/docs/40186/nmcu.pdf