source: Panasonic news

The capacitor is the industry’s first 6.3mm diameter and 30G vibration acceleration resistant characteristics. It will be launched in January 2018. Their compact diameter and stability for vibration is suitable to ECUs in automotive.

Osaka, Japan – Panasonic Corporation announced today that it has commercialized an anti-vibration, surface-mounted conductive-polymer hybrid aluminum electrolytic capacitor [1] suitable for use in power circuits for automotive electric control units (ECUs) employed in hybrid electric vehicles, electric vehicles, and gasoline-powered vehicles. The company will launch the capacitor in January 2018.

With the growing demand for eco-friendly cars, energy efficiency and the need to comply with environmental regulation, more ECUs are being employed in cars. Mechanical and electrical in-vehicle components are also becoming integrated [2]. This trend has created a need for more compact ECUs combined with better resistance to vibration. The capacitors employed to stabilize the voltage of a power circuit for the ECU and eliminate electronic noise are therefore increasingly required to be smaller in size and to show better anti-vibration performance. The company launches the industry’s first surface-mounted conductive polymer hybrid aluminum electrolytic capacitor which is only 6.3 mm in diameter and achieves resistivity of 30G high vibration acceleration.

Panasonic’s new conductive-polymer hybrid aluminum electrolytic capacitor have the following features:

- The capacitor is 6.3 mm in diameter and is highly vibration acceleration resistant, contributing to smaller and more vibration-resistant ECUs.

• Size: 6.3 mm in diameter, and 6.1 mm or 8.0 mm in height

• The newly developed capacitor withstands the vibration acceleration [3] of 30G The conventional capacitor*2 withstands vibration acceleration is 10G to the same aluminum electrolytic capacitor. - The capacitor renders unnecessary the anti-vibration techniques that are conventionally part of the board mounting process, thus allowing customers to streamline their production processes.

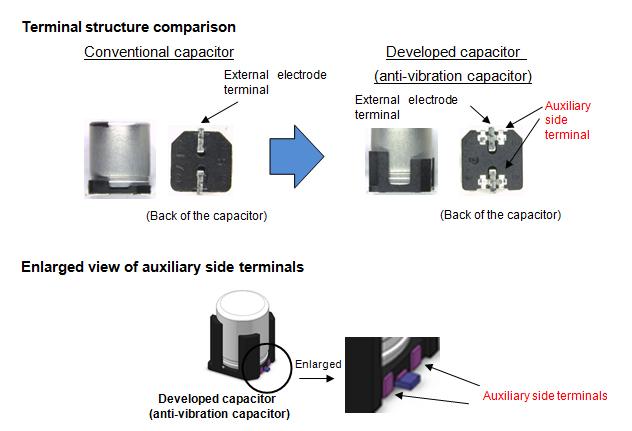

• It reduces the use of bonding-based reinforcing measures, such as attachment using adhesives. - The capacitor benefits from Panasonic’s unique auxiliary terminal structure, which offers highly reliable soldering properties.

Notes:

- *1: As a conductive polymer hybrid aluminum electrolytic capacitor with a diameter as low as 6.3 mm as of December 25, 2017 (Panasonic data)

- *2: Panasonic’s conventional product: conductive polymer hybrid aluminum electrolytic capacitor with a diameter of 6.3 mm

Suitable applications:

Power circuits for high-performance ECUs incorporated in hybrid electric vehicles, electric vehicles, and gasoline-powered vehicles, mechanical-electrical-integrated ECU circuits

Product Features

1. Anti-vibration capacitor achieving a 6.3 mm diameter for the first time in the industry that contributes to miniaturization of the ECU combined with effective resistance to vibration

The pressure to reduce the size, weight and number of power train-type ECUs mounted in cars has led to a change in their placement from the engine compartment to the engine itself. This has increased the need for the capacitors incorporated in ECUs of this type to be small, high-capacitance, and extremely anti-vibration. Currently, most capacitors with superior anti-vibration performance are 8 – 10 mm in diameter. The industry, however, needs a smaller type. Leveraging our own auxiliary terminal structure, Panasonic has commercialized anti-vibration capacitor with a diameter of 6.3 mm that withstands vibration acceleration of 30G for the first time in the industry. This new capacitor will contribute to miniaturization of the ECU and provide better overall resistance to vibration.

2. The new capacitor removes the need for anti-vibration reinforcement as part of the board mounting process, allowing customers to streamline their production processes

The conventional ECU board mounting process requires anti-vibration measures, such as anchoring components with adhesives, to make the ECU resistant to vibration if using non-vibration-resistant components. The developed capacitor has achieved anti-vibration performance high enough to withstand a vibration acceleration of 30G, making such anti-vibration measures unnecessary, thus allowing customers to streamline their production processes.

3. The capacitor has Panasonic’s unique auxiliary terminal structure that offers reliable soldering properties

This auxiliary terminal structure has auxiliary terminals positioned on the sides of the capacitor. This eases visual confirmation of auxiliary terminal soldering, ensures stable soldering properties, and enhances the ECU’s overall vibration resistance.

Basic specifications:

| Product series | ZA, ZC, ZK |

|---|---|

| Size (diameter x height) | Diameter 6.3 mm x height6.1 mm Diameter 6.3 mm x height 8.0 mm |

| Vibration acceleration | 30G (294 m/ s²) |

| Frequency | 5 – 2000 Hz |

| Amplitude | 5 mm |

| Resistance to vibration (direction, time) |

Vibration in the X, Y, and Z directions lasting for two hours each |

Term Descriptions

- [1] Conductive polymer hybrid aluminum electrolytic capacitor

- This is a capacitor containing a hybrid electrolyte made by mixing together a solid electrolyte (conductive polymer) and a liquid electrolyte (electrolytic solution). It combines a low-ESR (resistance) characteristic, which is one of the benefits of conductive polymer capacitors, with a low-leak current characteristic, which is one of the advantages of aluminum electrolytic capacitors.

- [2] Integration of mechanical and electrical components

- This refers to the integration of mechanical drive components and the ECU. Mechanical drive components and the ECU used to be physically separated but were interconnected via cables. Demand for high-precision control, a higher degree of freedom in component layout, reduction in number of cables, etc., has led to the adoption of an integrated configuration of mechanical and electrical components.

- [3] Vibration acceleration

- Vibration acceleration is a scale for expressing intensity of vibration.