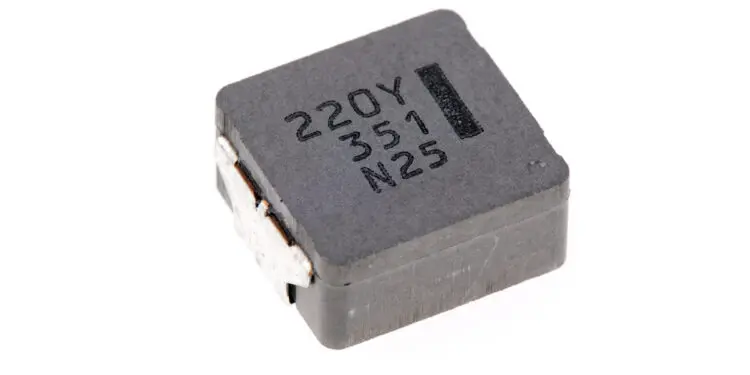

Panasonic released an application note on its low-loss power inductor (choke) within the fuel-injection solenoid circuit of an ECU featuring small size, ruggedness, and specifications tailored to the high-ripple-current dc-dc converter.

New inductor from Panasonic specifically targeting automotive engine control units (ECUs), which are increasingly located closer to the engine in what is a hot, vibration-intense, and generally nasty environment. The inductor in the dc-dc converter’s injector-boost circuitry must deal with high ripple currents that are always electrically and thermally stressful and challenging for long-term performance and reliability.

Performance required for injector boost coil:

- Low-loss and high withstand voltage

- Small size and large current

- High vibration resistance

- High efficiency of direct injection engine (shortening of boost recovery time)

- ECU space saving

- Installation of ECU in engine compartment and the integration of mechanical and electronic in-vehicle components

Features of Panasonic’s latest surface-mount automotive power chokes compared to their own predecessors:

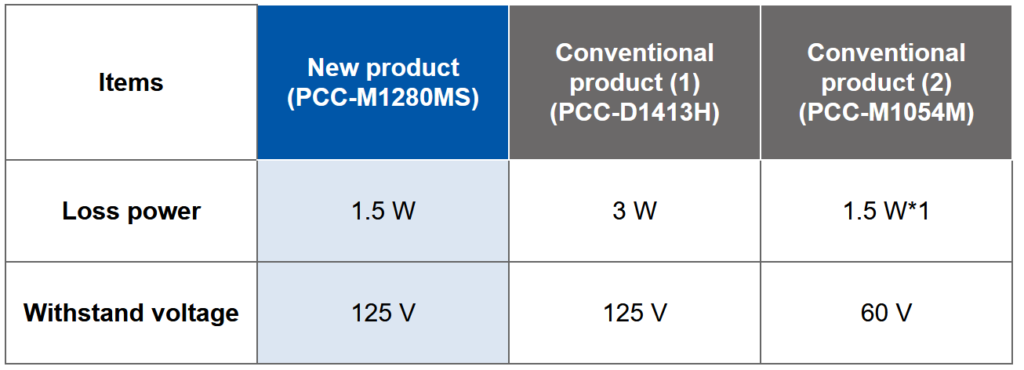

- Halved power loss and doubled high withstand voltage performance compared to conventional products through the use low-loss magnetic materials with high withstand voltage.

- The downsizing and the reduced number of coils required to be incorporated into ECUs due to the improved performance contribute to ECU space saving.

- The product eliminates the need for anti-vibration reinforcement as part of the mounting process, reducing the use of reinforcing measures with bonding agents (adhesives).

Detailed explanation of features

Halved power loss and doubled high withstand voltage performance compared to conventional products through the use low-loss magnetic materials with high withstand voltage.

Panasonic has developed new low-loss magnetic materials capable of handling large currents with a high withstand voltage based on metal composite materials using its in-house-developed metallic magnetic materials to commercialize a power choke coil with halved power loss and doubled high withstand voltage performance compared to conventional products.

These features will contribute to the improved performance and downsizing of automotive ECUs.

The downsizing and the reduced number of coils required to be incorporated into ECUs due to the improved performance contribute to ECU space saving.

The in-house-developed magnetic material and winding technology that forms the coil with high precision has enabled compactness and high performance, and the volume ratio has been reduced by 40% compared to the conventional product (1). And the number of components has been reduced compared to the conventional product (2). This contributes to ECU space saving.

The product eliminates the need for anti-vibration reinforcement as part of the mounting process, reducing the use of reinforcing measures with bonding agents (adhesives).

In conventional automotive ECU board mounting processes, reinforcement measures to fix components with bonding agents (adhesives) were necessary for ensuring the high vibration acceleration-resistant performance.

This product employs Panasonic’s original coil winding and forming technologies, which reduce the height of the terminal’s pull-out position down to half compared to the company’s conventional products.

Positioning closer to the mounting circuit board have achieved excellent vibration resistant performance.

This removes the need for anti-vibration reinforcement and contributes to the streamlining of the mounting process.

Example of use