There have been the coil of choice for generations of engineers – Ferrite inductors. With the rise of metal composite inductors, however, there has finally been a solution to address some immanent weak spots of the ferrite inductors. Thus the question is – can metal composite inductors make conventional ferrite designs completely redundant?

Metal Composite vs Ferrite Inductors Key Differences

In the following article, we try to answer this question by explaining the different characteristics that emerge from different material and structure, looking at the range of metal composite inductors available on the market.

The choice for downsizing

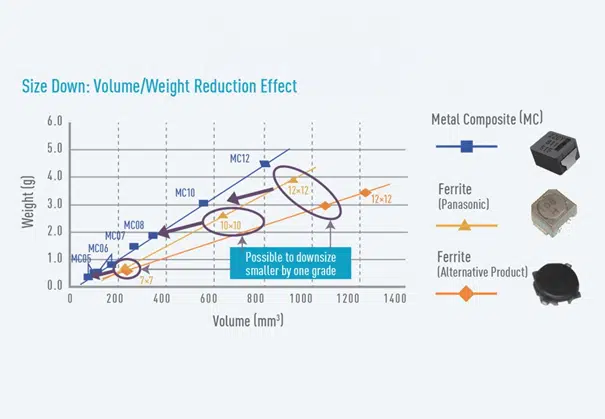

Metal composite inductors come with a remarkably higher energy density compared to their ferrite predecessors. This leads to 30% – 50% smaller case sizes which, for example, serves the trend for downsizing high current ECU power circuits. Furthermore, smaller case sizes also have the pleasant side-effect of being less prone to get damaged in harsh or vibrating environments. A true plus in terms of long term reliability.

See Figure 1. for volume vs weight comparison benchmark between metal composite chip inductors and different types of ferrite inductor types.

DC Bias characteristics

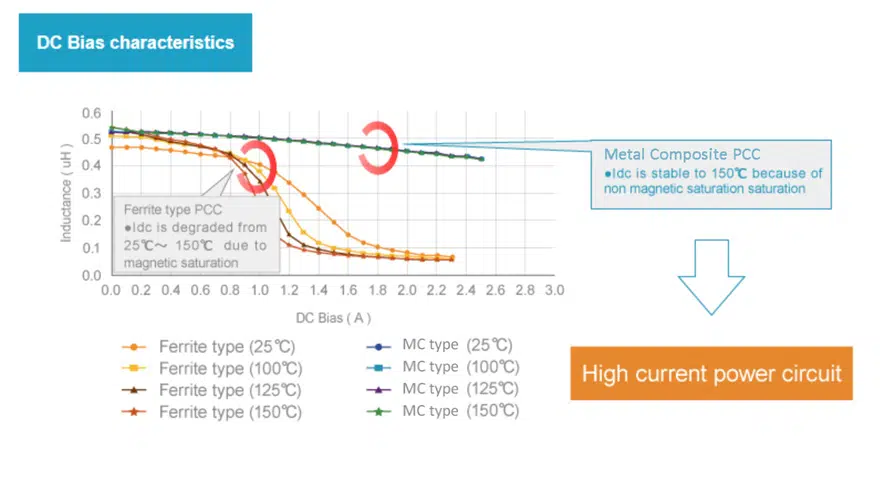

Excellent magnetic saturation characteristics of metal composite inductors (i.e. Ferrite core = 0.4T vs. Metal Composite Type = above 1.5T) render it difficult to magnetically saturate, which in turn is resulting in good inductance vs. current performance, without a substantial drop off. In comparison, ferrite inductors do not only suffer from a fairly quicker inductance drop off.

Their inductance also suffers the undesirable effect that it varies with temperature, whereas the performance of their metal composite counterparts is stable over the entire specified temperature range. Naturally, the qualification of applications using ferrite inductors needs increased effort compared to metal composite inductors due to consideration of different temperature ranges.

Low loss characteristics of metal composite vs ferrite inductors (see Figure 2.) assist realization of high efficiency power circuits such as ECU and makes thermal design considerations simple.

High Mechanical Shock and Vibration Robustness

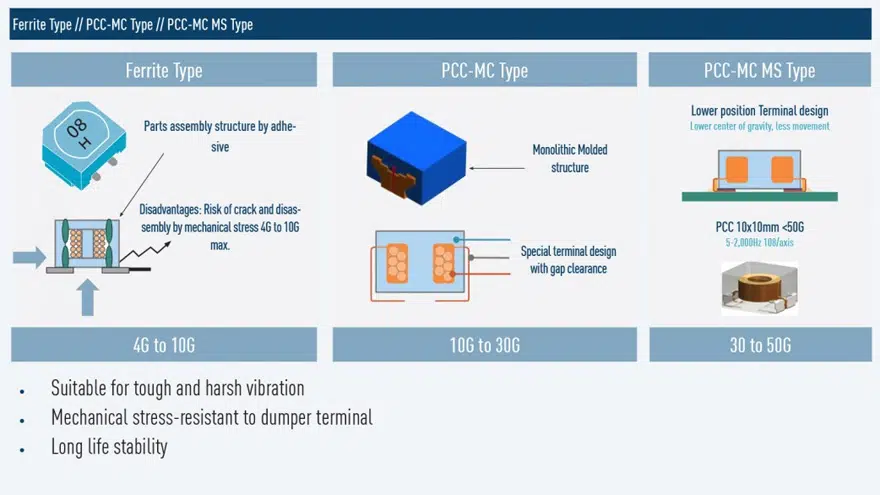

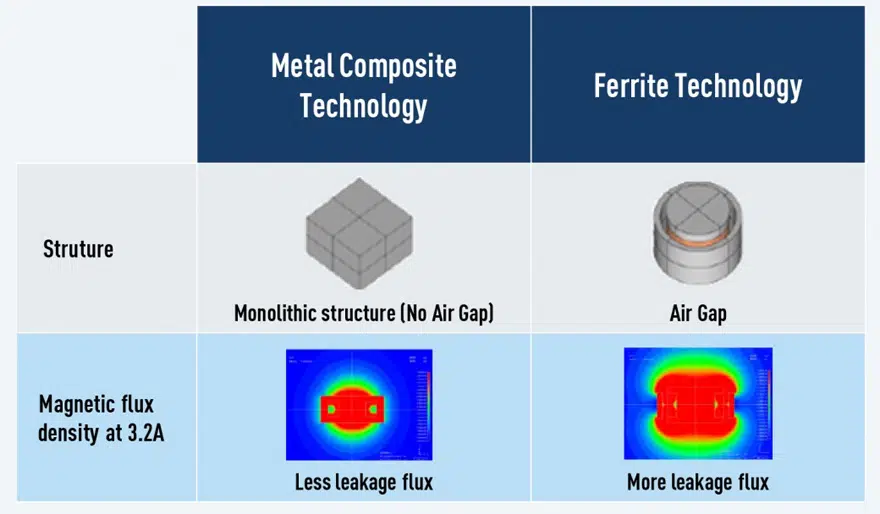

Ferrite inductors consist of several sintered parts being constructively composed with an air gap inside the body, whereas metal composite inductors are based on a monolithic design without air gap.

Due to that assembled structure, the ferrite types’ resistance to vibrations is limited to <4G to maximum 10G. Opposed to that, the monolithic structure of the metal composite inductors leads to a significantly higher vibration resistance – up to 50G, depending on the inductor type – See Figure 3. This may be advantage for harsh environmental, high vibration applications such as automotive, industrial or aerospace/defense electronics.

Low EMI noise

Also in terms of a lower leakage flux outside the power inductors, the point goes to the metal composite types: Their monolithic structure causes by far less leakage as the magnetic flux simply is concentrated inside the inductor housing. See figure 4.

Summary

Modern metal composite inductors clearly outperform ferrite technology in many regards and key requirements from modern electronic circuits. Hence, they are more and more finding their way into contemporary application design, in particular in the automotive industry.

Small package sizes, a stable inductance over DC current and temperature, high reliability as well as mechanical robustness and not at least a low EMI noise are nowadays essential prerequisites for next-gen product design. In all these aspects, metal composite inductors make their ferrite ancestors look as old as they are indeed.