At the time of powering on an electronic device such as a switch-mode power supply (SMPS) or an inverter, the device is charged with an instantaneous abnormal current with a high peak. It is called an inrush current, and without protection, it may destroy a semiconductor device or have a harmful effect on the service life of a smoothing capacitor. NTC thermistors are used as ICLs (inrush current limiters) to protect circuits of electrical and electronic devices against inrush currents easily and effectively.

Advantages of NTC thermistors

NTC thermistors are temperature-dependent resistors that employ special semiconductor ceramics with a negative temperature coefficient (NTC). They have a high resistance at room temperature, and when they are energized, they generate heat by themselves and the resistance falls as their temperature rises. With this property, they are used as current protection devices for electrical and electronic devices which easily and effectively limit abnormal currents including an inrush current at the time of powering on.

NTC thermistors used as current protection devices are also called power thermistors.A fixed resistance or an NTC thermistor can be used to limit inrush currents.

However, a fixed resistor always causes a power loss and a decrease in performance. An NTC thermistor limits an inrush current with its high initial resistance, and then its temperature rises because of energization and its resistance falls to a few percent of its level at room temperature, thus achieving a power loss that is lower than when a fixed resistor is used. In other words, the effect of limiting inrush currents obtained by using an NTC thermistor is greater than that obtained by using a fixed resistor with comparable initial power losses.

The following are details of sample applications of NTC thermistors for inrush current limiting.

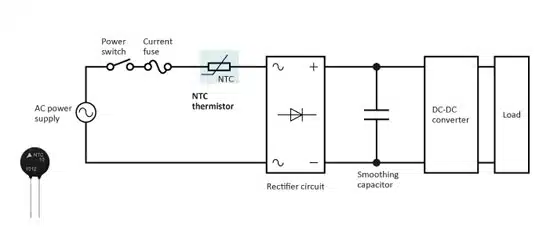

Application: Inrush current limiting in a switching power supply

Various switch-mode power supplies (SMPS) – which are small, lightweight, and high-performance – are often used as power supplies of electronic devices. At the time of powering on an SMPS, the device is charged with an inrush current with a high peak to charge a smoothing capacitor. Because this inrush current may negatively impact the service life of the capacitor, damage the contacts of the power switch, or destroy a rectifier diode, it is necessary to take countermeasures. As shown in the figure below, limiting the inrush current of an SMPS by inserting an NTC thermistor is widely used as a way of making a low-cost and easy circuit for limiting inrush currents in power supplies. The same result can be achieved even when the NTC thermistor is connected after the rectifier circuit.

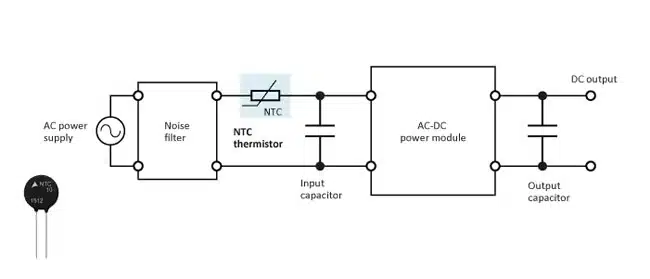

Application: Inrush current limiting in an AC-DC power module

A built-in power supply with various power circuits and peripheral circuits compactly integrated is called a power module. An AC-DC power module is a power supply constructed by combining an AC-DC rectifier circuit and a DC-DC converter, and with a small quantity of external parts, it can realize a space-saving optimized power supply system. An inrush current applied to input and output capacitors at the time of powering on can be effectively limited by inserting an NTC thermistor (power thermistor).

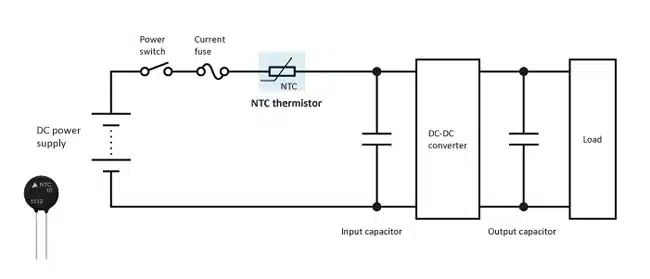

Application: Inrush current limiting in a DC-DC converter

In the DC power circuit of a DC-DC converter or the like, an NTC thermistor is used as a power thermistor and effectively limits an inrush current, with which the input and output capacitors are charged at the time of powering on. The resistance of the NTC thermistor becomes very low after it is energized, which achieves a power loss that is lower than when a fixed resistance is used.

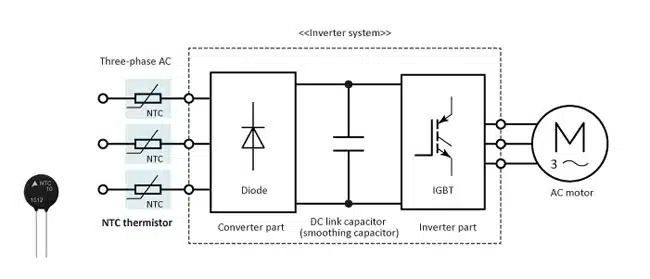

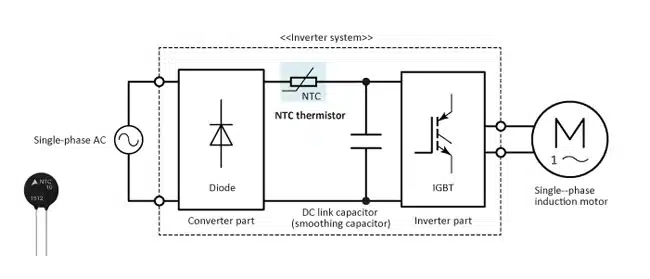

Application: Inrush current limiting in an industrial inverter

Induction motors are often used for fans, pumps, air conditioners, and others in factories, large facilities, office buildings, and the likes. An induction motor is simple in structure and stable, however, its rotation speed is dependent on the frequency. Inverters are needed in order to control the rotation speed. Motors equipped with inverters are known as variable speed drives (VSD), which are able to significantly reduce power consumption.

An inverter system consists of a converter part, an inverter part, and a DC link capacitor (smoothing capacitor) that is placed after the converter part. At the time of powering on, the device is charged with an inrush current of which whose peak is several times as large as larger than that of steady current to charge the DC link capacitor. This inrush current may have a harmful effect on the service life of a DC capacitor or destroy a semiconductor device. To protect against the inrush current, NTC thermistors (power thermistors) are connected.