Source: EPSnews

by EBN and Dr. Bill Cardoso, CEO of Creative Electron. Component shortages always prompt OEMs and EMS providers to seek alternative sources. Periods of scarcity also exacerbate the flow of counterfeit devices into the electronics supply chain.

The extent of this problem remains an unknown as incidents of counterfeits are under-reported. But there are estimates:

- The counterfeit semiconductor market has reached $75 billion according to Industry Week.

- Havocscope estimates that $169 billion in counterfeit parts are currently circulating in the marketplace.

- The United States Government seized $123,892 million in counterfeit electronics in 2016 (the most current year tracked by the Department of Homeland Security in its Year End Intellectual Property Rights Review).

EPSNews’ sister publication, EBN, recently interviewed Dr. Bill Cardoso, CEO of Creative Electron, to get his thoughts on the link between component shortages and counterfeit devices. Creative Electron is in the trenches of the battle against counterfeits, building x-ray inspection systems that identify fake parts.

EBN: What are the most difficult challenges facing component suppliers and OEMs today?

Cardoso: OEMs and EMS companies are facing the same issues with components and put simply: it is getting the right devices, in the right quantity to the line when they’re needed. I know that sounds like an over simplification, but it’s not. A surface mount technology (SMT) line can stop for many reasons, but the largest culprit is materials management. We invest millions trying to speed up the line and product changeover then we stop that line and lose efficiency because the component we need is missing, or even worse, incorrect.

It starts in the supply chain, where component shortages have occurred recently for several reasons, like companies trying to phase out devices and encourage redesigns. But it doesn’t stop there. When goods reach the factory, they need to be inspected and counted. Once in the factory material management systems they need to be tracked, spoilage and waste calculated, and their veracity ensured.

Veracity brings me to the other major challenge to the industry and that is counterfeiting. Counterfeiting is costing the industry billions and needs to be stamped out through detection and better materials traceability.

EBN: In the current electronics component shortage, customers are more willing to go to different sources. What advice do you have for OEMs about best practices to minimize counterfeit risk?

Cardoso: Absolutely, counterfeit numbers always grow when component shortages disrupt the supply chain. And yes, people have to get components from sources they may not normally like to use, like the grey market. The only two tools for counterfeit reduction are traceability and detection, and I’d suggest manufacturers need both.

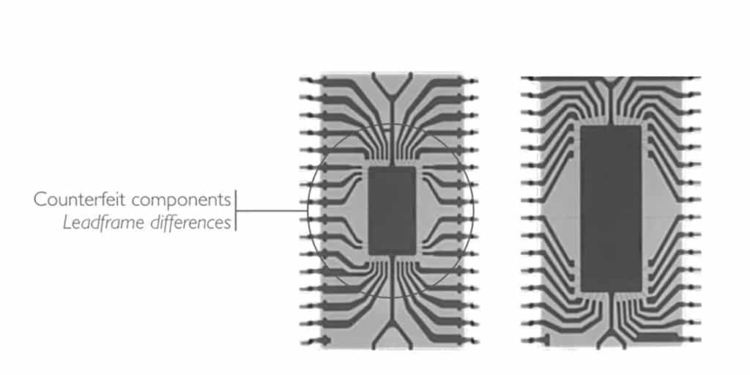

We have worked with numerous companies to assist in this area and counterfeit detection has become an important part of the products we offer. There’s a whole lot of advice and resources on our website about counterfeit detection using x-ray, including a great article written by our very own VP of Technology Dr. Glen Thomas, entitled ‘Counterfeit Detection Using X-Ray Image as a Fingerprint’.

We worked hard to make our customers lives as simple as possible in this area, using artificial intelligence (AI) to make detection simpler and more automated. Our AI systems are recognizing anomalies in component images and flagging them for further investigation.

My advice to manufacturers is have a fully traceable supply chain, but not to rely on it. Do your own inspection and test to make sure what you are putting on a PCB is what you and your customer is expecting! Whilst criminal, it’s important to remember counterfeiting is very profitable and the bad guys will go to a lot of effort to protect their business. It’s an arms race as they get smarter in producing and hiding counterfeits and we get better at detecting them.

EBN: How has component testing evolved recently? What should OEMs know about current capabilities and technologies?

Cardoso: As mentioned, the biggest development we see is the use of artificial intelligence to learn what a good component looks like and to throw up a flag when an outlier is detected. This needs to be done economically and at speed. We do it in our Parts Counter as a by-product of an essential process. Components are lost when reels are changed, so usage number do not tell the whole story. More and more manufacturers look to x-ray inspection for the exact number of components on a reel before it is returned to stores or delivered to the line. If we can check for counterfeits when we x-ray to count, that offer minimum disruption and no additional cost or investment.

What OEMs and EMS companies need to know is that solutions exist, are in relatively inexpensive and reliable. They will only get better, smarter and more reliable.

EBN: What trends are you seeing in terms of testing and how will those evolve over the next few years?

Cardoso: I think test and inspection data is fast becoming the currency of the smart factory and many people agree with me. I recently took part in a debate on this topic with vendors from AOI and Thermal Process inspection on that very topic chaired by one of your writers, Philip Spagnoli Stoten, during the APEX Expo in San Diego. This was picked up by EBN as Electronics Supply Chain Roundtable: Is Inspection Data the Currency of the Smart Factory?

For me, there is a clear trend towards data from inspection and test being used collectively to create better processes in manufacturing rather than just playing a go-no-go role. X-ray, like other non-contact optical inspections, is a unique process because of its non-destructive nature and has a huge role to play in delivering good contextualized data.

In my view inspection and test will become part of the solution, not merely the identification of the problem.

featured image source: Creative Electron