source: SMP news

Graben-Neudorf, Germany, February 2016. SMP Sintermetalle Prometheus GmbH & Co KG (SMP), German manufacturer of soft-magnetic materials and inductive components, based in Graben-Neudorf near Karlsruhe, has developed components for medical technology applications. These inductive components are used in Magnetic Resonance Imaging (MRI) or Computed Tomography (CT), for example. Designed as filter or mains chokes they are not only compact, low-loss and energy efficient but also exceptionally quiet in operation, essential qualities for these applications.

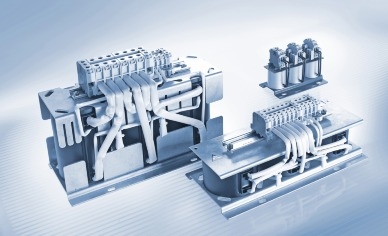

In MRI scanners, the components are installed in the “gradient amplifiers”, which supply output voltages and currents and control the gradient coils that encode the resonance signals for subsequent image reconstruction. The filter and mains chokes are designed to ensure a clean sinusoidal waveform and low-loss feedback of the unused energy.

Special magnetostriction-free materials, which SMP develops and produces according to individual customer specifications, ensure that components run very quietly. The powder composite materials feature low eddy current and magnetic reversal losses. The components are noted for their low loss balances and optimal EMC properties. They are also maintenance-free. The three-dimensional isotropy of the materials enables compact, lightweight structures, because the magnetic circuits are minimized. This also lowers the magnetic field strength, and the quantity of winding material used can be significantly reduced. The materials have a high saturation induction, up to 2 Tesla, and the oscillation behaviour of the choke can be adjusted specifically by using certain materials or appropriate, magnetically coupled designs with multiple coils.

Besides medical technology, SMP’s inductive components are used in industrial applications in power electronics, automation and signal processing, in drive engineering applications including railway technology, electromobility and maritime engineering, for renewable energies as well as conventional energies, and in the aerospace industry. Depending on their application, the components are designed either as single-conductor chokes for high-current applications, individual chokes, choke modules or LC filters. They can be manufactured with dimensions ranging from 19 mm to 300 mm, weighing from 0.05 kg to 130 kg, and up to temperature class H (up to 180°C). Protection classes up to IP66 are available depending on the intended application. All components are RoHS and REACH compliant, and CE and EAC certified. The materials used are UL listed.