source: EIN Presswire news

To support rising demand for its products, Ohmcraft—a leader in high-voltage resistor design and manufacturing— made more than $500,000 in capital investments.

ROCHESTER, NEW YORK, USA, March 2, 2018 /EINPresswire.com/ — To support rising demand for its products, Ohmcraft—a leader in thick-film, high-voltage, high-precision resistor design and manufacturing—recently made more than $500,000 in capital investments. The upgrades have enabled Ohmcraft to increase capacity and capabilities in its state-of-the-art manufacturing facility without compromising its unmatched lead times.

The new equipment includes a fully automated, high-speed screen printer with automated optical alignment, a custom high capacity belt furnace, and advanced test and measurement devices.

“As we enter new partnerships and expand our relationships with established accounts, it is essential that we not lose sight of what brought them to us in the first place—our ability to provide custom, precision resistors with extremely competitive turnaround times,” said Eric Van Wormer, Vice President of the Ohmcraft division of Micropen Technologies. “Our strategic capital investments have put us in an optimal position for current and future growth, while maintaining the level of service to which our customers are accustomed.”

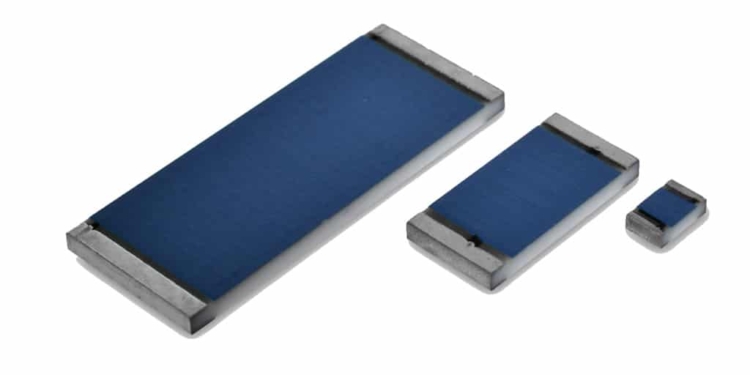

Ohmcraft’s thick-film, surface mount resistors are engineered to meet application specific needs in a variety of industries, including medical and military equipment. Its technology utilizes the proprietary Micropen electronic printing system to print precise, narrow, serpentine lines with resistive ink on a ceramic substrate, producing higher performance resistors over a wider range of values on a smaller surface area than is possible with conventional film resistor technology.