Researchers from Texas A&M University have found that a thin graphene supercapacitor can store energy by stretching and expanding when charged. This finding could lead to the development of new materials for flexible electronics and other devices that require strong durability and efficient energy storage.

Dr. Jodie Lutkenhaus, Associate Department head of Internal Engagement and Chemical Engineering Professor, worked with Dr. Dimitris Lagoudas, Professor of Aerospace Engineering, and Dr. James Boyd, Assistant Professor of Aerospace Engineering, on a new study published in Matter.

“We studied the stresses in graphene-based supercapacitor electrodes and linked them to the movement of ions within the material. When a capacitor is cycled, the electrodes store and release ions, leading to swelling and contraction.” – Dr. Jodie Lutkenhaus, Associate Professor and Department Head of Internal Engagement and Chemical Engineering at Texas A&M University.

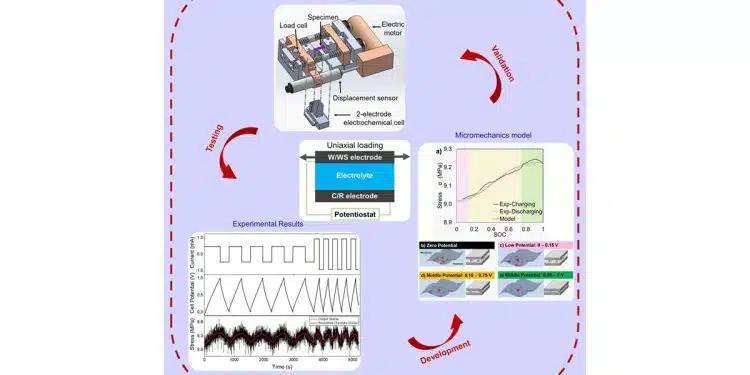

According to Lutkenhaus, this recurrent motion might result in the accumulation of mechanical stresses, which can lead to device failure. Her research aims to develop a device that detects mechanical stresses and strains in energy storage materials as they charge and discharge. The device provides insights into measuring the mechanical behavior of an electrode while charging and discharging, which can be difficult to detect in real-time.

Dr. James Boyd, Assistant Professor, Aerospace Engineering, Texas A&M University comments: “We are pioneering experimental methods to measure the simultaneous electrochemical and mechanical response of electrodes. Our research is now moving from supercapacitors to batteries.”

Mechanical damage reduces battery cycle life; hence, new hardware and models are required to interpret experimental observations to disentangle the impacts of mass diffusion, reactions, inelastic deformation, and mechanical damage. Internal and external mechanical forces can cause batteries and capacitors to fail. Internal stresses arise when batteries undergo repetitive cycling of the device, while external stresses might originate from impact or penetration of the device.

When these stresses occur, the battery needs to be able to survive the damage. According to Lutkenhaus, it is critical to understand how mechanical stress occurs in the device’s electrochemical state. Lutkenhaus added, “We developed an instrument that can do just that. By gaining this critical insight, we might be able to design safer energy storage devices that will last longer.”

The study’s goal is to create energy storage devices that can withstand structural loads and eventually replace carbon-fiber reinforced plastics used as structural panels in aircraft, boosting energy efficiency.

Read the full paper at:

Loufakis, D., et al. (2023) In situ electrochemo-mechanical coupling of 2D nanomaterial supercapacitor electrodes. Matter. doi:10.1016/j.matt.2023.08.017