Global Advanced Metals (GAM) blog note discusses importance of tantalum element as a material linked closely with electronic industry that meets challenging requirement for the next generation devices. Tantalum is used as the core material for tantalum capacitors as well as in the semiconductor technologies and alloy additives.

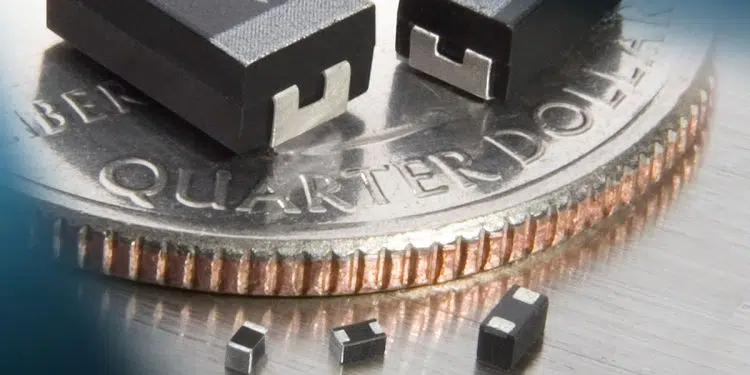

As electronic devices and technologies have evolved over the decades, they have become progressively smaller, more mobile, and more functional. This evolution is due, in large part, to advancements at the component level inside the electronic devices. While chip size and speed attracts many headlines, the surrounding components are also advancing rapidly which includes continuous improvements in tantalum capacitors. One need not look further than the high-tech watches that are now capable of so many new functions, such as health and well-being measurements. Similar to wearable watch advances, tantalum capacitors are also broadly used in implantable medical devices, enabling longer device reliability in smaller and smaller size. Some of these new devices can now be recharged from outside the body removing the need to open and replace. By offering high-performance in a tiny package, tantalum capacitor grade powder and tantalum capacitors are opening the door to a new generation of electronics.

Why Is Tantalum Such An Important Resource?

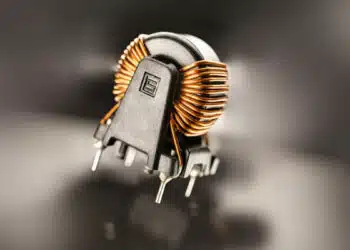

Several aspects of tantalum make it an important resource for the future. Its high degree of durability and reliability make it ideal for aerospace, military, medical, and industrial uses. In addition, a large portion of tantalum on the market is used for consumer electronics due to its high energy density – highest capacitance in a small dimension – enabling miniaturization and downsizing.

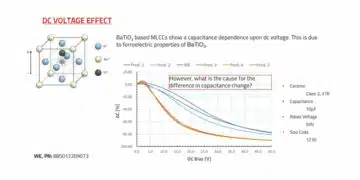

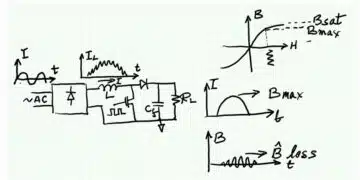

High energy tantalum capacitors allow designers of small electronics to overcome one of their greatest hurdles, finding materials that could handle more charge while remaining very small. Aluminum electrolytic or film capacitors can offer the same capacitance and voltage ratings as tantalum capacitors, but they must be significantly larger. For devices such as mobile phones and laptops, larger capacitors are often not a viable option. Ceramic MLCC capacitors support high level of miniaturization, however the same capacitance and voltage rated parts exhibit inferior characteristics and stability issues.

When it comes to tantalum capacitor’s importance for the next generation of electronic devices, the key points to remember are:

- Volumetric Efficiency

- Long-term Reliability

- Readily Available Raw Material

- High Charge Capability

- Wide Range of Temperature Tolerance

- Low Noise Generation

- Self-Healing Capability

- High mechanical robustness to shocks and vibrations

How Tantalum Enables Next Generation Electronics

As new and novel ideas for future electronics are further developed, the R&D branches of next gen electronics companies have started to embrace tantalum capacitor grade powder and tantalum capacitors as an enabling change agent.

Tantalum capacitor grade powder is enabling higher performance in the tantalum capacitors through providing powders that are of higher purity, cleaner, and have improved lot-to-lot consistency. Manufacturers of capacitor grade tantalum powder like Global Advanced Metals (GAM) have utilized continuous improvement efforts and novel approaches to improve the powder cleanliness which allows the capacitor manufacturers to better utilize the energy capability of the tantalum powder.

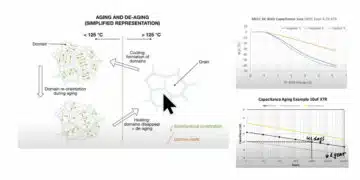

Tantalum capacitor manufacturers have also utilized continuous improvement and novel approaches to improve the capacitor performance for next gen electronics. Major improvements have been achieved in anode sintering technology and dielectric formation process enhancements to better capture the high CV offered in the tantalum powder. Further advancements by the tantalum capacitor manufacturers are allowing further miniaturization, lower internal resistance, improved reliability, and higher temperature capability.

Electronics will continue to become smaller and more functional as new technologies are developed. These innovations will be furthered by making full use of high-performance materials like tantalum.

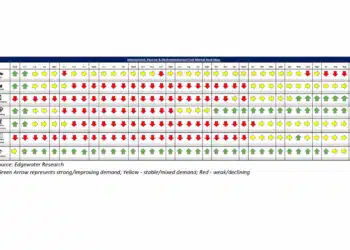

Where the Tantalum Marketing Is Going

The demand for tantalum only seems to be growing, and that growth is primarily due to its importance in next-generation electronics; however, there are many other uses for tantalum, including:

- Aerospace

- Military Projects

- High-Temperature Vacuum Furnaces

- Laboratory Equipment

- Nuclear Reactor Parts

- Servers and Solid State Drives

- Medical and Dental Implants

- Wearable Electronics

- Video Cards and Sensors in Automotive

- Radiation Shielding in Space Applications

- Heat Exchangers

- Instrumentation for Chemical Processing

- Surgical Instruments

Servers, Datacenters and Solid State Drives (SSD)

Tantalum capacitor grade powder and tantalum capacitors are finding favor in use for data storage. The appeal for tantalum capacitors in servers and SSD’s is built on the volumetric efficiency and temperature capability. This allows for smaller board size and a more dense server stack. Densely packed server stacks create thermal challenges that Ta capacitors are ideal to handle. Data processing and storage demands are accelerating with technologies that are currently being employed like 5G, assisted driving advanced driver-assistance system (ADAS), social media video content, and others.

Automotive EVs

Stability of electrical parameters under harsh conditions and long term reliability are key factors why tantalum capacitors are used on board of automotive applications from under the hood, dashboard, telematics, infotainment to ADAS critical systems. New generation of EV and HEVs are important drivers as well, with support from tantalum capacitors enabling downsizing without downgrading of performance and reliability.

Influence of 5G Technology

The high data speed of mmWave 5G networks in future smart cities requires new infrastructure to be built using network of micro/nano base stations in relatively short distance. Such small, low power, high performance base stations can be mounted on buildings, traffic lights, street lights etc in dense network. Tantalum capacitors present an ideal capacitor choice combining high electrical parameters stability & reliability at harsh (humid, rain, snow, hot) conditions and compact dimensions.

New Space and Deep Space Missions

Tantalum’s core feature is unprecedent reliability given by its construction and materials. Tantalum capacitors have been used on board space flights from day one and ready to meet the most critical missions. Its robust technology is ready to assist everyday quality of human life served from low-cost affordable low orbit satellite services or meet the challenging deep space missions to extend our human knowledge base.

Future Electronics

As the electronics industry continues to innovate with new and exciting products, tantalum capacitor grade powder and tantalum capacitors will be there to support. A perfect example is the emerging megatrend of augmented reality/virtual reality which will require high performance, high reliability in an ultra-small size which sits squarely in tantalum’s wheel-house. Also under design and development is continued use of electronic devices for medical, wearables and health monitoring and benefits. Tantalum capacitors are currently used in implantable medical devices and will find broader application in electronic devices focused on health and well-being.

The importance of tantalum in the development and advancement of the next generation of electronics cannot be overstated. Tantalum’s many advantages secure its place as one of the most sought-after metals in the modern world. At Global Advanced Metals, our mission is to provide the highest-quality and ethically-sourced tantalum available on the market. We look forward to continuing to be pioneers in the tantalum industry and helping our customers bring this technology to consumers.