High thermal conductivity plastics show extraordinary talents in transformer inductors, electronic component heat dissipation, special cables, electronic packaging, thermal potting and other fields for their good processing performance, low price and excellent thermal conductivity. High thermal conductivity plastics with graphene as filler can meet the requirements of high density and high integration assembly development in thermal management and electronics industry.

Conventional thermal conductive plastics are mainly filled with high heat-conducting metal or inorganic filler particles to uniformly fill the polymer matrix materials. When the amount of filler reaches a certain level, the filler forms a chain-like and network-like morphology in the system, that is, a thermally conductive network chain. When the orientation direction of these heat conductive mesh chains is parallel to the heat flow direction, the thermal conductivity of the system is greatly improved.

High thermal conductive plastics with carbon nanomaterial graphene as filler can meet the requirements of high density and high integration assembly development in thermal management and electronics industry. For example, the thermal conductivity of pure polyamide 6 (PA6) is 0.338 W / (m · K), when filled with 50% alumina, the thermal conductivity of the composite is 1.57 times that of pure PA6; when adding 25% the modified zinc oxide, the thermal conductivity of the composite is three times higher than that of pure PA6. When the 20% graphene nanosheet is added, the thermal conductivity of the composite reaches 4.11 W/(m•K), which is increased by over 15 times than pure PA6, which demonstrates the enormous potential of graphene in the field of thermal management.

1. Preparation and thermal conductivity of graphene/polymer composites

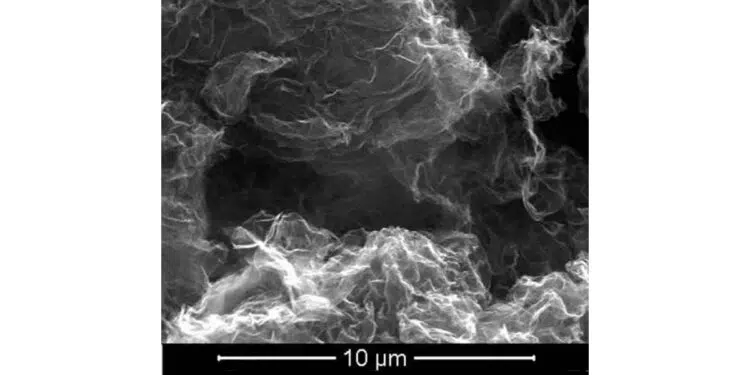

The thermal conductivity of graphene/polymer composites is inseparable from the processing conditions in the preparation process. Different preparation methods make a difference in the dispersion, interfacial action and spatial structure of the filler in the matrix, and these factors determine the stiffness, strength, toughness and ductility of the composite. As far as the current research is concerned, for graphene/polymer composites, the degree of dispersion of graphene and the degree of peeling of graphene sheets can be controlled by controlling shear, temperature and polar solvents.

2. The factors affecting of the performance of graphene filled high thermal conductivity plastics

2.1 Addition amount of Graphene

In the high thermal conductivity plastic filled with graphene, as the amount of graphene increases, thermal conductive network chain is gradually formed in the system, which greatly improves the thermal conductivity of the composite material.

By studying the thermal conductivity of epoxy resin (EP)-based graphene composites, it is found that the filling ratio of graphene (about 4 layers) can increase the thermal conductivity of EP by about 30 times to 6.44. W/(m•K), while traditional thermal conductive fillers require 70% (volume fraction) of the filler to achieve this effect.

2.2 Number of layers of Graphene

For multilayers graphene, the study on 1-10 layers of graphene found that when the number of graphene layers was increased from 2 to 4, the thermal conductivity decreased from 2 800 W/(m•K) to 1300 W/(m•K). It follows that the thermal conductivity of graphene tends to decrease with the increase of the number of layers.

This is because the multilayer graphene will agglomerate with time, which will cause the thermal conductivity to decrease. At the same time, the defects in the graphene and the disorder of the edge will reduce the thermal conductivity of the graphene.

2.3 Types of substrate

The main components of high thermal conductivity plastics include matrix materials and fillers. Graphene is the best choice for fillers because of its excellent thermal conductivity. Different matrix compositions affect thermal conductivity. Polyamide (PA) has good mechanical properties, heat resistance, wear resistance, low friction coefficient, certain flame retardancy, easy processing, suitable for filling modification, to improve its performance and expand the application field.

The study found that when the volume fraction of graphene is 5%, the thermal conductivity of the composite is 4 times higher than that of the ordinary polymer, and when the volume fraction of graphene is increased to 40%, the thermal conductivity of the composite is increased by 20 times.

2.4 Arrangement and distribution of graphene in matrix

It has been found that the directional vertical stacking of graphene can improve its thermal conductivity. In addition, the distribution of the filler in the matrix also affects the thermal conductivity of the composite. When the filler is uniformly dispersed in the matrix and forms a thermally conductive network chain, the thermal conductivity of the composite is significantly improved.

2.5 Interface resistance and interface coupling strength

In general, the interfacial compatibility between the inorganic filler particles and the organic resin matrix is poor, and the filler particles are easily agglomerated in the matrix, making it difficult to form a uniform dispersion. In addition, the difference in surface tension between the inorganic filler particles and the matrix makes it difficult for the surface of the filler particles to be wetted by the resin matrix, resulting in voids at the interface between the two, thereby increasing the interfacial thermal resistance of the polymer composite.

3. Conclusion

High thermal conductivity plastics filled with graphene have high thermal conductivity and good thermal stability, and their development prospects are very broad. Besides the thermal conductivity, graphene has other excellent properties, such as high strength, high electrical and optical properties, and is widely used in mobile devices, aerospace, and new energy batteries.