Sotiris Zorbas, Power Εlectronics Εngineer of Frenetic in this blog explains benefits of 2-Chamber Approach in transformer designs and prove its usefulness in resonant Converters, like in the half bridge LLC Converter.

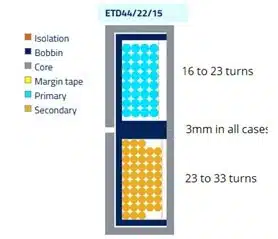

As shown in featured image Figure 1, the transformer primary and secondary windings are separated by a plastic barrier. In low frequency Transformers, that is useful because of its isolation benefits. That is true also for HF

Magnetics, but besides the isolation, this winding arrangement approach offers some additional benefits, such as:

- Isolation between high-low voltage windings.

- Primary-secondary capacitance is kept to a minimum.

- Leakage inductance can be adjusted by modifying the barrier thickness between windings.

- A resonant inductor can be omitted if the leakage inductance is properly chosen.

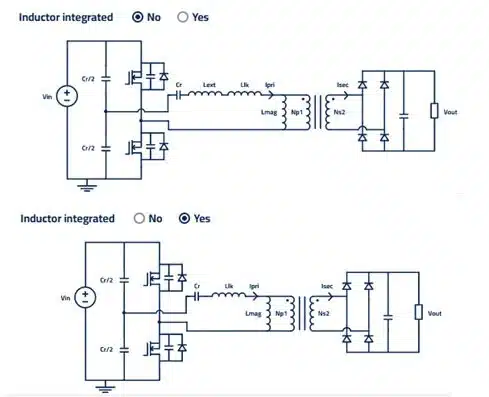

Let’s focus now on the last two key points just listed, and let’s use the popular half bridge LLC topology for our analysis as shown in Figure 2.:

In this screenshot taken from Frenetic Online, you can see the button on the top asking if the series resonant Inductor should be included into the Transformer or not. In theory, we care about the sum of these 2 inductances: if the Llk of the transformer is not enough, we have to add in series Inductor for the sum of two to have the correct value. But, if we modify the Llk to have the final value of series inductance, then we don’t need an external inductor at all!

See where I’m going with this…

The half bridge topology offers some benefits versus the full bridge up to about 2kW, where the high rms currents are causing high losses and the adoption of the full bridge is clearly advantageous.

I tried to create x5 designs with different power levels in order to prove that the 2-chamber approach can be successfully chosen for higher power level applications. But, prior to unfolding these design, I want to focus first on the concerns I had before even starting the simulation in Frenetic Online.

List of concerns…

- Splitting the available bobbin room in 2 will force me to use multiple layers to fit the windings. That can be very troublesome at high power levels, where skin and proximity losses rule the game and are directly dependent on the layer count. Could I control the winding losses given the constraints?

- Could I achieve the necessary magnetizing/leakage inductance combo without huge gaps in the core that would create EMI and extra fringing losses on the winding, perhaps?

- Could I achieve a good power density, so that the designs wouldn’t be large and bulky?

- Could I achieve 50-50% balance between core-winding losses in all cases, which is the right step achieving optimal temperature rise numbers?

Simulations

The Verdict

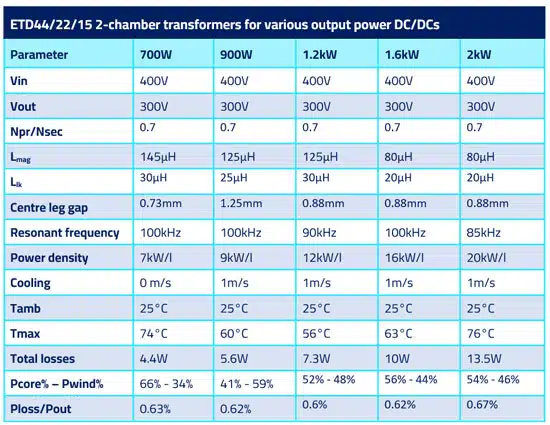

Table 1 answers all the concerns and questions I had before! Here all the findings:

- The power level was raised by 30% in each simulation, from 700W up to 2kW. A ~30% increase is observed in the total Transformer losses in each case, which is easily observed looking at the stable Ploss/Pout ratio, very stable at 0.62%. Only the design at 2kW starts deviating going to 0.67% of losses. That is a good indicator that moving up in power, selecting windings and layout carefully, can keep the winding losses under control. And this answers my first concern mentioned previously.

- Core-winding losses are designed to be relatively equal at the 400->300V operating condition.

- I kept the barrier at 3mm, the leakage inductance at 20-30μH and a center leg gap <1.25mm in all five cases. That ensures manufacturability and low noise emissions. The gap effect is insignificant since (as shown in Figure 3) both primary and secondary windings are far from it. The closer to the gap, the higher the fringing losses. In our cases the barrier helps to avoid this.

- Power density is moving from 7kW/l up to 20kW/l. Actually, below 6-8kW/l usually no forced air cooling is needed to achieve 40-60°C of temperature rise in a magnetic component. You can keep this as a rule of thumb for your designs, no matter the topology. At 700W we have a 7kW/l power density and ~50°C of temperature rise (74-25=49°C) with free convection. In the rest of the designs 1m/s was used.

- To remember LLC calculations (how to select Lmag, Llk) for half bridges, watch webinar on the topic here.

- These designs prove that a reasonable power density, thus compact design, can be achieved up to 2kW, which is the useful power range limit of the half bridge LLC topology, without the need for an external inductor!

Maybe you can come up with a Transformer + Inductor design that is denser than suggested, but is it worth the extra component and cost? Is the total power density of the x2 components higher than the one of the 2-chamber transformer?