Simon Ndiritu from General Dielectrics explains some basic guidelines for capacitor technology selection in switch mode power supplies.

Introduction

Switch mode power supply systems (SMPSs) are widely used in today’s electronic systems. They are popular mainly due to their impressive efficiency, light weight, and low volume. The reliability of a power supply greatly determines the lifetime of an electronic system. In the case of personal computers, 90% of failures can be attributed to SMPS-related issues. As such, power supply systems are expected to provide high reliability.

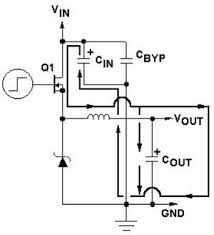

Capacitors are essential components of a switch mode power supply system. Both the input and output stages of a SMPS system have capacitors. At the input, a rectifier and a capacitor are used to convert AC voltage to DC voltage. The output stage consists of an LC filter, a combination of a capacitor and an inductor, that removes noise and ripple voltages.

A typical switch mode power supply system has the following key components: an input rectifier, an input filter, power switches, a power transformer, an output rectifier, output filters, and a control circuit. The input and output filtering capacitors of a SMPS are selected depending on the electrical performance requirements. These capacitors significantly determine the reliability of a SMPS system.

Selecting capacitors for SMPS filtering

The key factors that you should consider when selecting a capacitor for SMPS filtering applications include equivalent series resistance (ESR), equivalent series inductance (ESL), capacitance density, temperature characteristics, dielectric constant, voltage characteristics, frequency characteristics, and cost. The types of capacitors that are commonly used for input and output filtering in switch mode power supply systems include aluminum electrolytic, tantalum, ceramic, and film capacitors.

Aluminum electrolytic capacitors

For a long time, power systems designers have used aluminum electrolytic capacitors for input and output filtering in switch mode power supply systems. These capacitors offer a superior capacitance per unit volume, and they are inexpensive. The high CV of aluminum electrolytic capacitors is achieved by depositing thin layers of dielectric material on etched aluminum metal foils. The superior capacitance density and relatively low cost of these capacitors make them a popular choice for filtering applications in SMPSs.

On the flip side, aluminum electrolytic capacitors have high equivalent series resistance. The construction of these capacitors is the main cause of this high ESR. This high ESR is a major problem in high frequency applications. In addition, the performance of aluminum electrolytic capacitors is significantly affected by exposure to high temperatures.

Evaporation of the electrolyte reduces the life of aluminum electrolytic capacitors. In addition, these capacitors have polarity and failing to connect them correctly can cause failure. Moreover, when subjected to over-voltage conditions, an aluminum electrolytic capacitor can explode.

Tantalum capacitors

Tantalum capacitors offer high levels of capacitance, and they are commonly used in SMPS filtering applications. A tantalum capacitor has a highly porous anode that provides a large dielectric surface area, hence the extremely high CV density. As compared to aluminum electrolytic capacitors, these capacitors have better performance characteristics for filtering applications in switch mode power supply systems. Nevertheless, the cost of producing these capacitors is higher than that of aluminum electrolytic capacitors.

At high frequencies, tantalum capacitors exhibit relatively high equivalent series resistance and significant loss of capacitance. Some filtering applications require capacitors with high voltage ratings. Tantalum capacitors are less effective for such applications. In addition, the performance of tantalum capacitors is significantly affected when they are subjected to multiple charge/discharge cycles. Moreover, these capacitors have high leakage currents and may contain toxic ingredients.

Ceramic capacitors

A variety of dielectric materials are available for designing ceramic capacitors. The choice of the material mainly depends on the desired performance characteristics. The impressive performance characteristics of ceramic capacitors make them a suitable option for input and output filtering in SMPS systems. Both ceramic disc and multilayer ceramic capacitors (MLCCs) are used in SMPS filtering. Although ceramic disc capacitors are stable over a wide range of temperatures and are suitable for applications that demand high voltage ratings, many manufacturers have switched to multilayer ceramic capacitors, due to their CV density.

Multilayer ceramic capacitors are capable of attaining high capacitance levels. The potential for high capacitance levels is one of the factors that make these capacitors a suitable option for input and output filtering in SMPS systems. Most ceramic capacitors for SMPS filtering applications are based on Class II dielectric materials. As compared to Class I dielectric materials, Class II materials offer a higher dielectric constant. The properties of a Class II X7R dielectric material make it one of the widely used materials for designing capacitors for switch mode power supply filtering. Although Class II materials offer a higher dielectric constant, they exhibit reduction in dielectric constant when exposed to DC voltage and ageing.

As compared to aluminum electrolytic capacitors, tantalum capacitors, and film capacitors, multilayer ceramic capacitors have lower equivalent series resistance. This property helps to minimise power loss in SMPS filters. Furthermore, low ESR helps to reduce output ripple voltage, and this makes multilayer ceramic capacitors a better option for output filtering in SMPSs. In comparison to other capacitors used for SMPS filtering, multilayer ceramic capacitors offer better ESL. They also have better capability of handling ripple current. Moreover, MLCCs come in a variety of physical formats and a wide range of temperature ratings, usually up to 250oC. This property makes them a suitable option for SMPS filtering in automotive, military, down-hole drilling, and other high temperature applications.

The construction process of ceramic capacitors involves firing them at high temperatures. The fired ceramic material is strong in compression but weak in tension. As such, subjecting these capacitors to mechanical stress can result in component failure. Moreover, the construction of ceramic capacitors increases their susceptibility to thermal shock. It is, therefore, important to consider operating conditions when selecting a capacitor for SMPS filtering applications. Furthermore, as compared to aluminum electrolytic and tantalum capacitors, MLCCs have lower CV density.

Film capacitors

Film/foil and metallized film capacitors have impressive self-healing properties. Most film capacitors use polypropylene or polyester dielectric material. Polyester is readily available and offers a high dielectric constant. On the other hand, polypropylene has a relative low dissipation factor. Polyester-based film capacitors are mostly used in applications that require a high volumetric efficiency while polypropylene-based capacitors are mainly used for high current DC and high voltage/high frequency AC applications. The construction of film capacitors allows them to withstand extreme transients, making them a better option for SMPS filtering in high current applications. In addition, film capacitors are light, small in size, and relatively inexpensive to produce.

Although film capacitors have impressive characteristics that make them a suitable option for many SMPS filtering applications, they have limitations. To start with, these capacitors have higher ESR and ESL as compared to ceramic capacitors. In addition, film capacitors are not suitable for high temperature applications. Although some film capacitors are rated at 125oC, most of them are unsuitable for temperatures above 105oC. In AC applications, film capacitors can fail if they are exposed to over-voltage. This failure is caused by corona.

Conclusion

The performance and reliability of a switch power mode supply system is greatly determined by the input and output filtering capacitors. The types of capacitors that are commonly used for filtering applications in SMPSs include aluminum electrolytic capacitors, tantalum capacitors, film capacitors, and ceramic capacitors. The type and amount of capacitors to be used for a specific application mainly depend on the operating conditions of the power supply. Selecting suitable filtering capacitors helps to maximize the reliability of a switch mode power supply system.