This article written by Vincent Mao, Joe Hock, Caleb Winfrey KYOCERA-AVX Corporation delves into capacitor ripple current evaluation and testing as an increasingly relevant test to complement design considerations.

The world is shifting towards electrification, with electric vehicles (EVs), renewable energy, and smaller, more powerful, yet efficient system-on-chips (SOCs) emerging as key components.

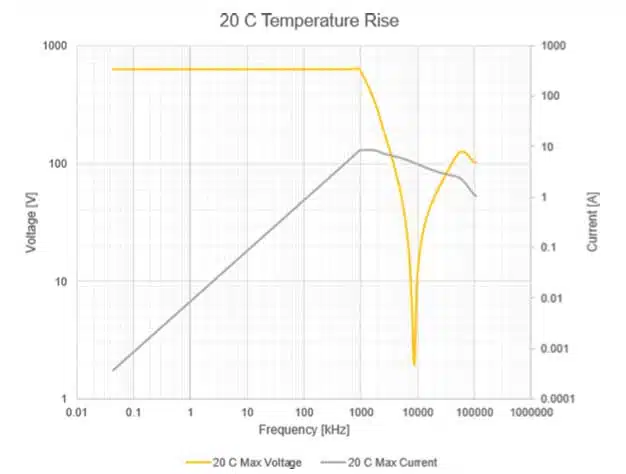

This shift is driven by the growing concern about signal and power integrity across various environments. The ripple current test is commonly used to assess device performance up to 20°C above room temperature.

This overview focuses on the test setups employed to cover three ESR tiers (low, medium, and high) for applications spanning signal integrity to microwave/RF. We present initial results, procedures for data collection and analysis, and considerations for performance impacts associated with mounted parts. Additionally, we discuss ongoing challenges in this field.

Introduction:

In the evolving landscape of electrification—spanning electric vehicles (EVs), renewable energy, and advanced system-on-chips (SoCs)—ripple current has emerged as a critical factor affecting both signal and power integrity. Traditionally relevant in CPU design, ripple current now significantly impacts industries like automotive electronics. This document explores ripple current testing as an essential complement to design considerations, focusing on its relevance in assessing performance under varied environmental conditions and applications.

Key Points:

- Ripple Current Significance: Ripple current affects heat generation in capacitors due to equivalent series resistance (ESR) and has become increasingly relevant beyond traditional computing applications.

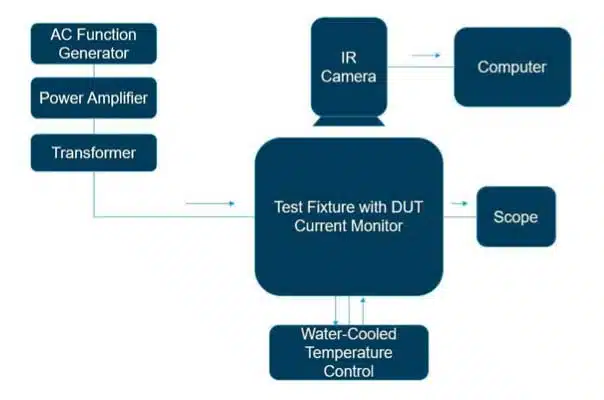

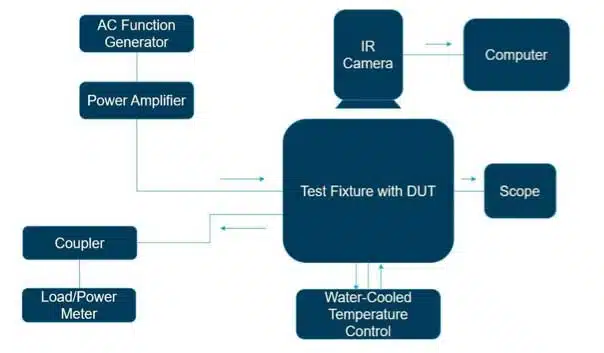

- Test Setup: Involves a combination of signal generators, power amplifiers, impedance matching components, and thermal monitoring apparatus.

- Capacitor Types: The study analyzes NP0, X7R, and Tantalum capacitors, each with unique ESR characteristics influencing ripple current tolerance.

- Data Collection & Analysis: Encompasses impedance characterization, progressive voltage application, and thermal monitoring to determine ripple current limits.

- Design Implications: Provides insights into optimizing power delivery and ensuring component reliability across various environments.

Extended Summary:

The increasing prevalence of embedded systems and the shift towards electrification underscore the growing importance of ripple current in electronic design. Ripple current, the AC component superimposed on a DC supply, affects the thermal performance and reliability of capacitors due to its relationship with ESR. This document details a comprehensive ripple current test designed to evaluate capacitor performance across diverse applications, from RF/microwave systems to automotive electronics.

The ripple current test setup is sophisticated, incorporating function generators, power amplifiers, impedance matching devices, and thermal imaging equipment to assess both unmounted and mounted device configurations. These setups are tailored to accommodate different ESR tiers and frequency ranges, extending up to 1 GHz for high-frequency applications.

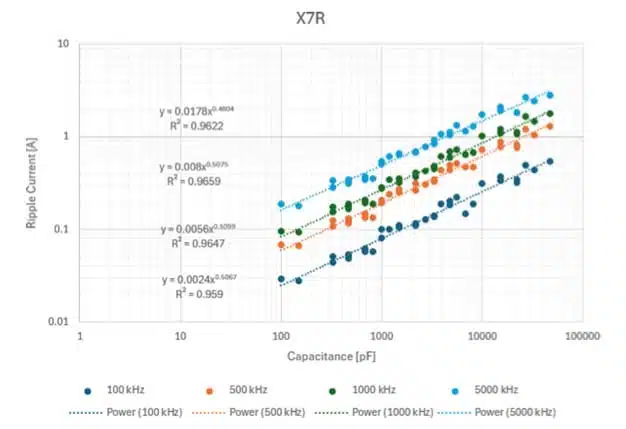

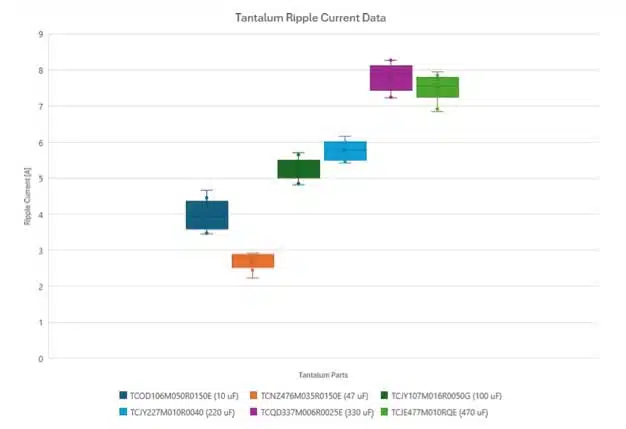

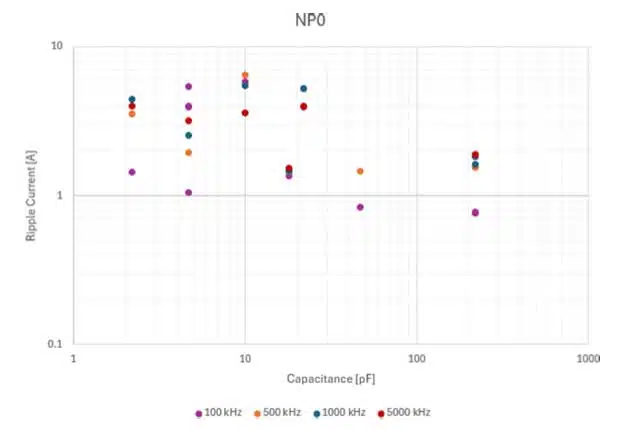

Three capacitor types—NP0, X7R MLCC capacitors, and Tantalum capacitors were studied. NP0 capacitors, known for minimal ESR and temperature stability, support high ripple currents, making them ideal for high-frequency applications. X7R capacitors offer stable performance over a broad temperature range and exhibit moderate ESR, suitable for general-purpose applications. Tantalum capacitors, with higher ESR, demonstrate self-healing properties and are robust under high ripple current conditions, beneficial for automotive applications.

The data collection process involved impedance and ESR characterization using precision analyzers, followed by progressive voltage application to observe thermal responses. Data analysis revealed trends correlating capacitance, frequency, and ripple current tolerances. Notably, lower ESR corresponds with higher ripple current capabilities. The study identified the need for ongoing data collection to refine predictive models, particularly for NP0 and Tantalum capacitors.

Future modifications aim to enhance test setups for higher frequency data capture and minimize measurement discrepancies. Improved models will support design decisions in EV charging systems, power-efficient circuits, and high-frequency applications, ensuring component reliability and performance across diverse operational environments.

Conclusion:

Ripple current testing is vital for modern electronic design, providing critical insights into component behavior under dynamic conditions. By understanding the interplay between ripple current, ESR, and capacitance across various capacitor types, designers can optimize electronic systems for durability, efficiency, and reliability. Ongoing research and data refinement will continue to enhance these insights, supporting the development of robust, future-ready electronic solutions.

read the full paper: