Basic Principles of Connectors

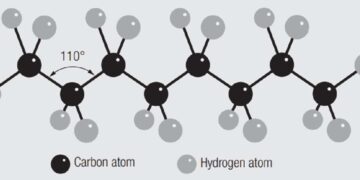

Polymer Materials and Processing

The majority of connector housings are manufactured from thermoplastic polymers due to their combination of electrical and mechanical properties and...

Read moreDetailsFeedback from Connector Failure Analysis

In this paper SERMA TECHNOLOGIES presents failure statistics of connectors from field return analyzed during the last 10 years. The...

Read moreDetailsUnderstanding Cable Skew: A Key to High-Speed Signal Integrity

As the demand for faster data transmission intensifies, engineers must confront an often-overlooked challenge—cable skew. In high-speed digital systems, even...

Read moreDetailsEMI Shielding Considerations with Connectors

Samtec compiled a list of frequently asked questions about EMI shielding and connectors. Do shielded connectors and cable assemblies help...

Read moreDetailsConnector Materials and Processes

This article will provide a basic discussion of connector materials and manufacturing processes. Chapter I/1.4.1 Contact Finish Electroplating on contact...

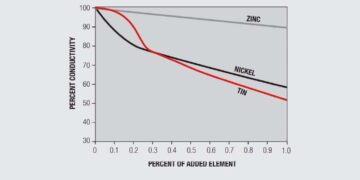

Read moreDetailsCopper Alloy Metallurgy and Processing

The majority of connector contacts are manufactured from copper alloys due to the combination of high electrical conductivity and good...

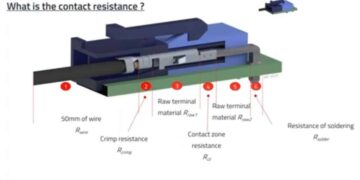

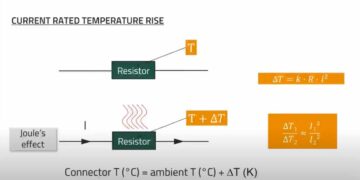

Read moreDetailsHow to Make a Good Electrical Contact for Inter-Connection

This Würth Elektronik webinar explains influence of different parameters and how to make a good electrical contact for reliable inter-connection....

Read moreDetailsConnector Inrush Current Explained

Würth Elektronik podcast explains connector inrush current considerations and discusses what other values need to be considered when selecting a...

Read moreDetailsHow Much Gold is Needed for Connector Plating

This blog written by Samtec discusses how much gold is needed to specify on the connector pins plating. Gold Plating...

Read moreDetailsSix Essential Tips To Select The Right Connector

This blog written by Samtec aims to give you six design tips from a connector company on selection of the...

Read moreDetails