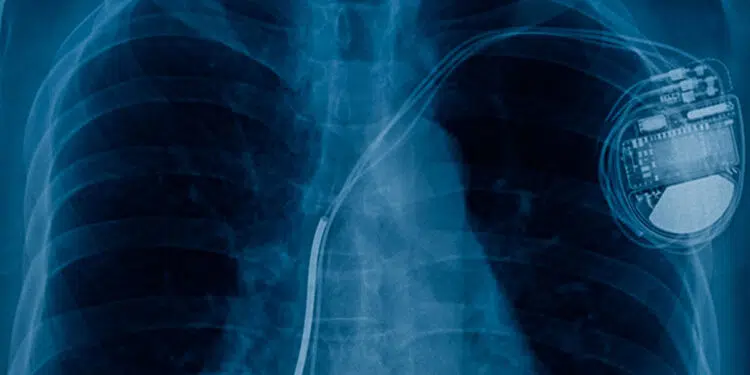

From systems that diagnose, like a magnetic resonance imaging (MRI) machine, to implantable devices that treat patients, like pacemakers and implantable cardioverter-defibrillator (ICDs), highly reliable electronic components are necessary. Shiraz Vakharia of Knowles highlights some of the application-specific decisions medical device designers need to make.

While the functionality of these devices is quite different, the challenges associated with designing these devices, such as selecting failsafe electronic components designed for lifetime reliability and ensuring supplier partners can meet industry-specific standards, are shared. Let’s look more closely at some of the industry-wide challenges associated with electronic component selection for medical devices as well as some of the application-specific decisions medical device designers need to make to ensure these devices function consistently and reliably for the long term.

High-reliability components

Medical device manufacturers are regulated by agencies such as the International Standards Organisation and the US Food and Drug Administration in order to maintain the highest level of reliability. While the purpose of these organisations is to set standards to ensure medical devices maintain the highest level of reliability, the burden should not fall solely on medical device designers.

Instead, device designers should make sure the tight controls placed on them for the design, development and manufacture of these devices are also met by the suppliers they select for components such as multi-layer ceramic capacitors (MLCCs), single-layer capacitors and trimmer capacitors.

For example, developing a device that needs to function at high voltages, such as an ICD that operates at 600V or 900V, components need to be designed and tested to withstand voltages much higher than the device’s typical operating voltages. A medical device designer needs to involve suppliers in discussions on component selection and be completely transparent with voltage requirements.

Additionally, to safeguard reliability, the designer should be sure that the supplier is performing burn-in tests at elevated voltage and temperature levels and that all components are 100% electrically tested and visually inspected to conform to strict performance criteria.

Regulatory challenges

In addition to preventing device failure by selecting a supplier dedicated to providing high-reliability components for the medical industry, medical device designers need to be sure the electronic components they use comply with a variety of industry specifications. The two main specifications for most medical components are MIL-PRF-55681 and MIL-PRF-123.

In essence, MIL-PRF-55681 is the specification most widely used in the field of medical implantable devices. It defines a mid-K stable dielectric designated as BX. The MIL-PRF-123 specification covers the general requirements for high reliability, general purpose (BX and BR dielectric options), and temperature stable (BP and BG) ceramic dielectric fixed capacitors for both through-hole and surface-mount devices.

As well as a thorough understanding of these two standards, and any others that may be needed for a specific application, a supplier needs processes in place for operations, testing and quality assurance. It also needs to provide documentation, such as source control drawings (SCDs) that govern every aspect of the components supplied. This is a critical, yet sometimes overlooked, part of the design process. SCDs provide an engineering description, qualifications and acceptance criteria for the delivery of specialised components for critical applications. This type of documentation can make it easier for device designers to ensure compliance with relevant standards and regulations such as MIL-PRF-55681 and MIL-PRF-123.

EMI in implantable devices

Beyond these general industry-wide considerations for reliability, there are some additional application-specific challenges for medical electronics.

For example, today there are many sources of conducted and radiated electromagnetic interference (EMI) that can potentially disrupt the function of implantable medical devices. This could involve throwing off the rhythm of a pacemaker or causing an ICD to falsely sense an irregular heartbeat, sending a shock that is not needed.

To eliminate EMI and reduce these risks, medical device designers can use a feedthrough filter made from a multi-layer planar array or discoidal capacitor. These feedthrough filters are used at a connection point to ensure that unwanted noise, such as EMI, is eliminated, preventing issues such as voltage spikes.

This method for filtering EMI involves a capacitor shaped like a doughnut with leads which carry signals that pass straight through the capacitor. The capacitor’s exterior is attached to the EMI shield, which forms a Faraday cage around the protected circuit. With these filters mounted in the wall of the Faraday cage, any incoming or outgoing cables will pass through the filters, which will filter out high-frequency conducted interference, while the Faraday cage protects against radiated interference.

The horizontal electrodes within the capacitor act as extensions to the Faraday cage wall, which can result in excellent high-frequency performance. Filtered feedthroughs have a low equivalent series resistance and equivalent series inductance, and can be hermetically sealed instead of being sealed with a resin. These filters are designed for high- or low-voltage devices.

Components in MRI equipment

MRI machines and all medical equipment used in them, such as patient-monitoring devices, require special reliability considerations. One of the biggest issues that medical device designers run into with MRI machines is that all components used in or around the machine cannot exhibit any magnetism. This is challenging because a standard MLCC may contain a base metal electrode made of nickel, or the dielectric and electrode may use a nickel barrier finish to prevent solder leaching at terminations – yet nickel is ferromagnetic.

To create a reliable and stable non-magnetic MLCC termination, suppliers are limited in the materials they can use. Two recommended options include a silver palladium (AgPd) sintered termination or a copper barrier layer. While an AgPd termination is a good option, it is prone to solder leach, which can lead to performance issues. On the other hand, a copper barrier will not have issues with solder leaching, but it may be susceptible to oxidisation and corrosion. It is, however, compatible with lead-free and conventional soldering options and is also less expensive than AgPd.

Another necessity when eliminating magnetism is to use non-magnetic dopants, or additives, in ceramic dielectrics. Different combinations of elements can be used to create the correct dielectric properties and eliminate magnetism, but that can limit the capacitance ranges available.

No matter what type of medical device is being designed, it is likely to be getting smaller and more powerful with each generation. This does not change the need for device designers to meet requirements and regulations to ensure the equipment will maintain lifetime reliability.

To be sure selected electronic components will not be the cause of issues with a device in the long run, it is good practice for designers to consult a specialty components manufacturer at the beginning of the design process. Suppliers that are already familiar with handling the complexities that come with high-reliability, high-temperature and high-frequency applications are well-equipped to provide the electronic building blocks that will ensure that any medical device is built to last.