Heraeus Electronics has announced the successful acquisition of the PriElex electronics inks business line from Kayaku Advanced Materials.

The acquisition, effective January 31, 2024, strengthens Heraeus Electronics’ Thick Film business and expands its portfolio of offerings for the electronics materials industry.

PriElex has developed a strong reputation in the sector, by joining forces with Heraeus Electronics the acquisition enables Heraeus Electronics to enhance its position and provide customers with an even broader range of high-quality and innovative solutions for thick film applications.

“We are excited to welcome PriElex into the Heraeus family,” said Mark Challingsworth, Global Head of Business Line Thick Film Materials at Heraeus Electronics. “This acquisition reinforces our commitment to deliver exceptional product quality- tailor-made and in-time, technical support, and customer service to our valued customers. The integration of PriElex’s expertise and technology will enable us to offer a more comprehensive and tailored portfolio of solutions for thick film applications.”

Heraeus Electronics’ Thick Film business is globally recognised for its broad range of thick film materials. With our cutting-edge technologies and in-depth understanding of the industry, we have established ourselves as a reliable partner in enabling the success of various electronics applications across numerous sectors.

Partners and customers of both Heraeus Electronics and PriElex can expect a smooth transition and ongoing support throughout the integration process. Furthermore, customers can be assured of uninterrupted service and access to a broader portfolio of advanced solutions.

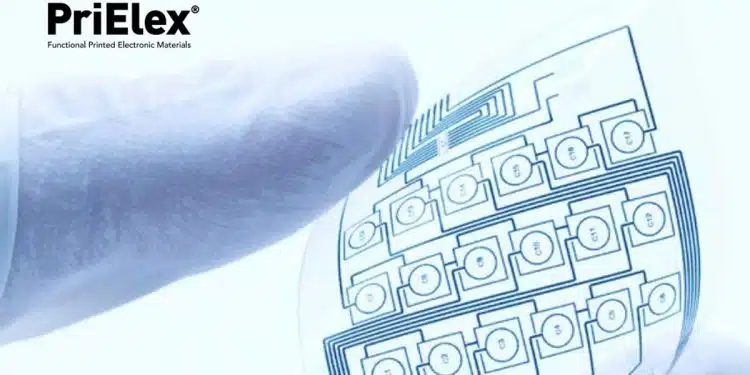

Polymer Thick Film (PTF) pastes, also known as electronic inks or low-temperature pastes, have revolutionized the way we think about designing and manufacturing electronic devices. With their unique properties and versatility, they offer countless opportunities for engineers and product developers to create cutting-edge solutions.

Benefits of PTF Pastes

- Flexibility and adaptability: PTF pastes are designed to be applied onto flexible substrates, enabling the production of lightweight, bendable, and even stretchable electronic components. This opens up a world of possibilities for applications in wearable devices, smart textiles, flexible displays, and more.

- Low-temperature curing: Unlike traditional thick film pastes, PTF pastes can be cured at relatively low temperatures, eliminating the need for high-temperature processing. This makes them compatible with heat-sensitive substrates like polymers, paper, and even fabrics, expanding the range of materials that can be used in printed electronics.

- Cost-effectiveness: PTF pastes offer a cost-effective alternative to traditional manufacturing methods such as etching or sputtering. Their compatibility with large-scale printing processes, such as screen printing and inkjet printing, allows for high-volume production at a lower cost, making them ideal for mass-market applications.

- Versatile material properties: PTF pastes can be formulated with a wide range of conductive, resistive, and dielectric materials, giving engineers the freedom to tailor their properties for specific application requirements. Whether you need high conductivity, low resistance, or insulation capabilities, PTF pastes can be customized to meet your exact needs.

- Integration with conventional manufacturing processes: PTF pastes can seamlessly integrate with existing manufacturing processes, enabling the creation of hybrid circuits that combine the benefits of printed electronics with the reliability of conventional electronic components. This allows for a smooth transition from traditional PCB-based designs to advanced hybrid systems.

- Environmental friendliness: PTF pastes are typically solvent-based, reducing the need for hazardous chemicals compared to other manufacturing techniques. Additionally, the compatibility with low-temperature processing reduces energy consumption, making PTF pastes a more environmentally friendly choice for electronic manufacturing.

The applications of PTF pastes are virtually endless. From smart packaging, medical devices, and novel heating technology to automotive electronics and IoT sensors, PTF pastes can be utilized in a wide range of industries. They offer engineers and product developers the freedom to explore new design concepts and bring innovative solutions to life.

Applications:

- Medical devices and Biosensors

- Circuits and Sensors

- Low temperature Heaters – PTC and fixed resistance

- Passive Components

- RFID

Typical Products:

- Ag Conductor inks: AG-500A, AG-510, AG-515-1, AG-800, AG-919, AG-1074, WB-1078, Z-904, LTC3602, LTC3650

- Ag/AgCl inks: AGCL-675, AGCL-1134 (50/50), AGCL-1194 (65/35), LTC3701(65/35)

- Carbon ink: C-250J

- Conductive epoxy: EP-600 (2-part)

- Potting compounds: EP-799 Potting

- Dielectric inks: UV-2530, UV-2531, UV-3010, UVD5271

- Radio Opaque inks: RO-593, RO-948