This article written by Kevin Cho, KYOCERA-AVX Corporation discusses the distinctions between aluminum electrolytic and metal film capacitors before considering some distinct advantages of film capacitors and the self-healing properties of metallized film capacitors.

Abstract:

In high voltage, high energy applications such as electric trains and solar power grids, the safety and reliability of capacitors are paramount.

Catastrophic failures and associated explosions or fires are unacceptable. Just as importantly, service lifetime and predictability for optimizing up-time are critical to the product’s success.

Film capacitors with controlled self-healing are the ideal solution to these challenges and can be obtained in various sizes and technical specifications.

Energy Storage Capacitors

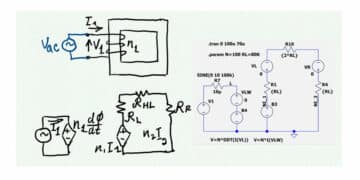

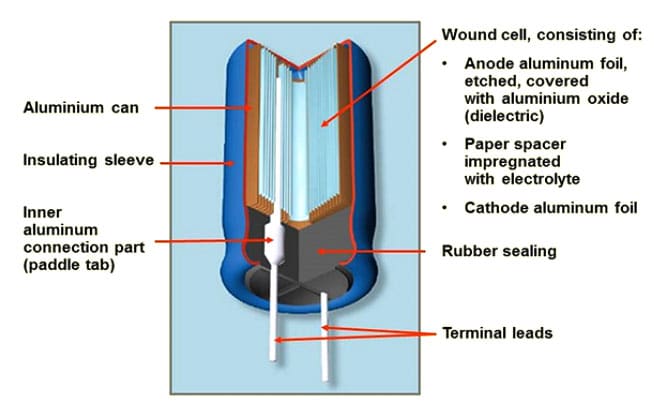

High voltage capacitors for energy storage are generally divided into two distinct technologies: aluminum electrolytic and metal film. Electrolytic capacitors rely on an aluminum oxide dielectric grown on aluminum foil electrodes to form the basic structure. These foils are wound and electrically contacted with an electrolyte-soaked paper separator, as shown in Figure 1.

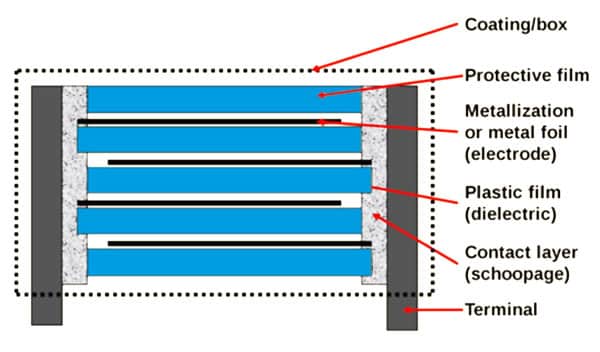

On the other hand, metal film capacitors rely on a metallized dielectric film to form the capacitive structure. Many film materials are available – most commonly, polypropylene and polyester. As shown in Figure 2, the metallized film is wound and contacted on either end to form an elementary capacitor, which is then stacked in series or parallel to realize higher voltage, higher-capacity devices.

Aluminum electrolytics tend to be cost-effective in applications requiring high capacitance values at DC voltages less than 800V. These applications include DC-DC converters, motor starters, and frequency converters. When higher voltages are required, especially in non-polarized AC circuits, metal film capacitors are the only alternative option. Some example applications include sample and-hold circuits, snubbers, and peak voltage detectors.

However, as shown in Figure 3, both types of capacitors have tradeoffs that significantly overlap in their application spaces. For example, either capacitor may be used in lighting ballasts, noise filters, and DC blocking circuits depending on the design constraints.

Film Capacitor Advantages

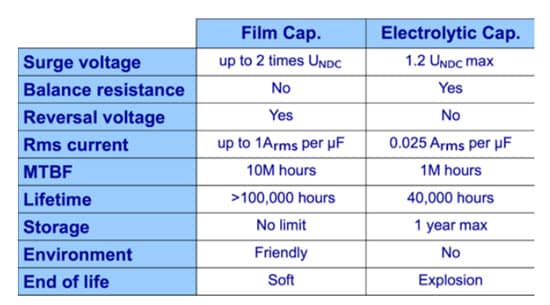

While aluminum electrolytic capacitors are a cost-effective solution in many designs, certain characteristic requirements may inhibit their use. The following table presents some critical parameters that may necessitate choosing a film capacitor for a particular application.

Current reversal, life-time, and end of life failure mode are three of the most critical parameters to consider. Current reversal is impossible in aluminum electrolytics because the oxide dielectric is initially grown on the aluminum electrodes via anodization. Reversing the voltage on such a structure results in a breakdown of the dielectric and eventual failure. Similarly, the overall lifetime and failure modes of aluminum electrolytics are

undesirable.

The oxide dielectric layer gradually breaks down, and the loss of electrolyte results in lower voltage tolerance and gas generation. Eventually, the device will fail in a short circuit condition and potentially explode or cause damage to supporting devices.

Controlled Self-Healing

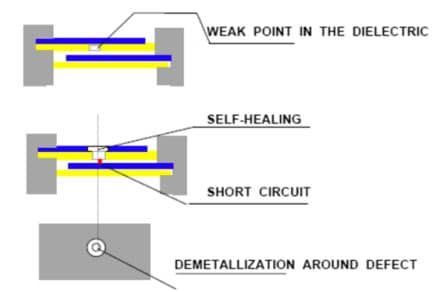

Metallized film capacitors exhibit a self-healing property that significantly improves their lifetime reliability characteristics. Figure 4 depicts the basic process wherein a dielectric defect results in a high current, high-temperature short circuit that quickly demetallizes the surrounding area.

Unfortunately, this mechanism can be difficult to control, and in the worst case, a run-away process can result, causing the destruction of the entire capacitor in short order. To avoid this, KYOCERA AVX developed a controlled self-healing process in 1974 based on the segmentation of overall capacitance into elementary cells protected by fuse gates.

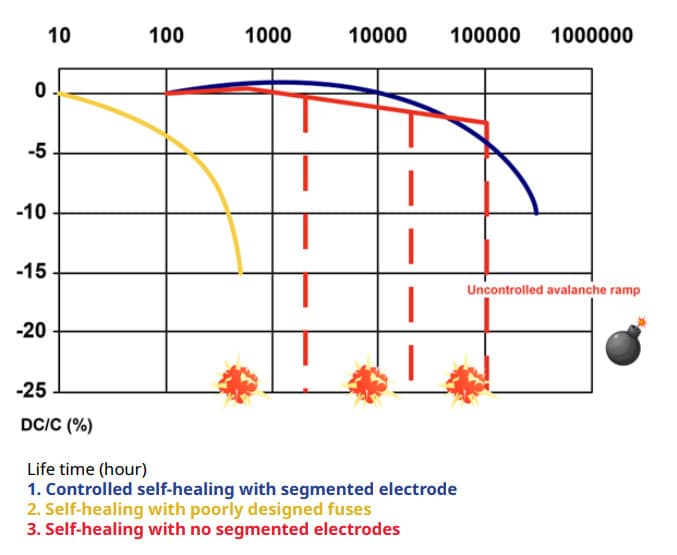

A micrograph is shown in Figure 5a, where an elementary capacitive cell has experienced a defect, and the resulting overcurrent condition has broken all four of its fuses – Figure 5b. This isolates the defective cell without affecting the remainder of the capacitor. Also shown is the overall reduction of capacitance over time as more and more of these elementary cells go off-line.

This controlled self-healing technique is now the standard construction for all KYOCERA AVX’s film capacitor solutions, including dry, no free oil, and oil impregnated. As a result, these capacitors experience no catastrophic failure (short circuit). Just as importantly, the decrease in bulk capacitance over time is well modeled and directly measurable, allowing for an accurate prediction of capacitor lifetime and determination of an optimal service schedule.

Figure 6 presents three lifetime curves of capacitance change to illustrate the point. The red line is the worst-case scenario with no self-healing strategy. The degradation is unpredictable and may result in a catastrophic failure. The yellow line uses a fused design for control, but the fuses are improperly sized for the elementary cell. The device fails prematurely through rapid loss of capacitance over time. The blue line presents the KYOCERA

AVX design, where decades of experience have yielded a design with no catastrophic failure and an extended, highly predictable lifetime.

KYOCERA AVX Capacitors for Reliable Self-Healing Protection

As of December 2020, KYOCERA AVX has delivered 8.6 million dry film capacitors with an estimated cumulative lifetime of 391 billion hours. Of these, there have been zero catastrophic failures. Such a track record of safety and reliability is unparalleled and speaks to design quality while validating the core self-healing technology.