Source: doEEEt article

Surface mount ceramic capacitors, such as MLCCs, for use in Defense and Aerospace applications usually require a superior level of reliability. To achieve high reliability, capacitor suppliers follow MIL-PRF standards for manufacturing, processing, qualification, and testing and are tightly controlled for design changes and material traceability. Historically, all MLCCs utilized precious metal electrode (PME) technology and is currently the predominate technology in use for high reliability Defense and Aerospace applications.

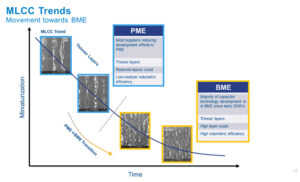

However, when we look at the commercial and automotive trends over the past 30 years, we can see major advancements in technology ranging from PCs, to laptops, cell phones, smart phones, electric vehicles, IoT, autonomous vehicles, and so on. Functionality and circuit density have increased exponentially over time, which means active and passive component size must decrease at the same pace.

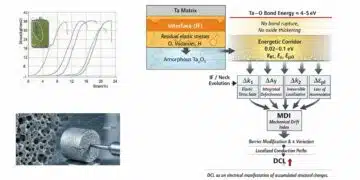

In order to shrink the size of MLCCs, while maintaining the same capacitance values, dielectric layers must become as thin as possible. In fact, making MLCC layers thinner is the driving factor for increasing volumetric efficiency. Since MLCCs historically used PME technology, suppliers ran into limitations on how thin the dielectric could be made, while maintaining reliability.

Therefore, Base Metal Electrode (BME) technology was introduced in the early 2000s, which allowed suppliers to create much thinner layers, drastically increase volumetric efficiency, and decrease cost.

Today, BME MLCCs make up the overwhelming majority of MLCCs in used in the electronics industry. These also include many applications where reliability is critical. For example, the automotive industry has been using BME technology for over 15 years in applications such as ABD systems and airbags. The medical industry has been using BME MLCCs in instrumentation and implantable devices for over 10 years.

BME vs PME

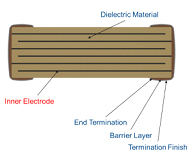

MLCCs are constructed using alternating layers of ceramic dielectric and metal electrodes. BME MLCCs use nickel as the conductive inner electrodes and are the predominant technology for MLCCs today. PME MLCCs use precious metals such as silver or palladium as the inner electrodes. The use of precious metal electrodes increase cost and prevent thinner layers making them poor candidates for high density applications.

The conversion from PME to BME technology in MLCCs helped enable the trend of miniaturization and circuit density for every industry except one, the Defense and Aerospace industry.

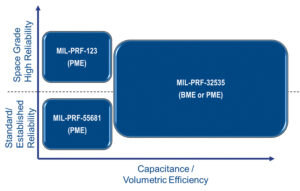

The two predominant specifications for high reliability MLCCs are the MIL-PRF-55681 and MIL-PRF-123. The MIL-PRF-55681 specification has been around for over 25 years and customers will only use PME MLCCs qualified to this standard. Since this is limited to PME, Defense and Aerospace customers cannot capitalize on miniaturization trends and limits circuit density.

The MIL-PRF-123 specification prevents the use of nickel electrodes (BME MLCCs) and therefore is limited to PME technology, which, as mentioned previously, Defense and Aerospace customers cannot capitalize on mediatization trends and limits design density. This led to the creation of a new standard for high reliability MLCCs, MIL-PRF-32535.

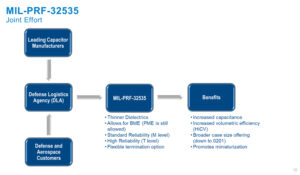

The creation of the MIL-PRF-32535 specification is a joint effort between the Defense Logistics Agency (DLA), leading capacitor manufacturers, and defense/aerospace customers. The new standard allows for thinner dielectrics and the use of BME technology while maintaining the same reliability levels as MIL-PRF-55681 and MIL-PRF-123. In addition, MIL-PRF-32535 is the first standard to allow for a flexible termination to increase flex robustness.

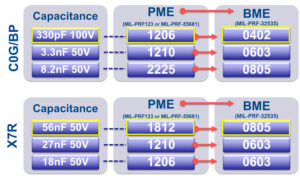

By utilizing BME technology and thinner dielectrics, this specification allows defense and aerospace customers to take advantage of the increase capacitance and smaller case sizes. For example, thanks to the increased volumetric efficiency of BME vs PME, it is possible to replace 18 1206 1nF PME MLCCs with one 1206 18nF BME MLCC.

Not A Replacement

The MIL-PRF-32535 specification is not intended to replace MIL-PRF-123 or MIL-PRF-55681 but rather allow for thinner dielectric MLCCs and BME technology.

By allowing thinner dielectrics and BME technology, higher capacitance values in the same case size and voltage ratings can now be achieved. Therefore, the MIL-PRF-32535 specification can be thought of as an extension to the legacy standards that have been in place for many years.

KEMET MIL-PRF-32535 are available in M (standard reliability) and T (high reliability) product levels

KEMET was one of the capacitor manufacturers at the forefront of specifying the details behind the MIL-PRF-32535. So much so that KEMET was the first manufacturer to provide capacitors built to the new standard.

The KEMET Hi-Rel BME capacitors are available in a wide range of voltages and case sizes and in both X7R and C0G dielectric platforms.