Researchers from China published article titled “Enhancement of high-temperature capacitive energy storage performance in all-polymer dielectric composites via microphase separation” in Applied Physics Letters.

Abstract

Polymer dielectric capacitors play a crucial role in modern electronics and power systems owing to their exceptional power density, high breakdown strength, excellent processability, and cost-effectiveness. Nevertheless, their practical deployment in harsh operating environments, particularly in electric vehicles and aerospace power electronics, remains challenging due to the inherent thermal instability of conventional polymer dielectrics. Herein, we report an all-polymer dielectric composite (APDC) material fabricated from partially miscible polyetherimide (PEI)/polyamide-imide (PAI) blends that exhibits significantly improved high-temperature capacitive energy storage properties, including breakdown strength (Eb), discharge energy density (Ud), and charge–discharge efficiency (η). The performance enhancement stems from the self-assembled nanoscale interfacial architectures comprising uniformly dispersed PAI domains within the PEI matrix, coupled with the intrinsic energy band structure mismatch between PEI and PAI (notably in electron affinity). These structural characteristics effectively create deep charge traps, resulting in a substantial reduction of leakage current density by more than one order of magnitude compared to pristine PEI under elevated temperatures and high-electric fields. Notably, the developed APDC materials feature a straightforward, efficient, and cost-effective fabrication process, rendering them highly promising for scalable production of high-performance dielectric films for high-temperature capacitors.

Introduction

Polymer dielectric film capacitors are essential in electronics due to their impressive energy storage properties and ease of manufacturing. However, their performance drops significantly in high-temperature environments, which limits their use in advanced applications like electric vehicles and aerospace power systems.

This article explores a novel approach to overcoming this limitation by designing all-polymer dielectric composites using microphase separation of polyetherimide (PEI) and polyamide-imide (PAI).

Key Points

- All-polymer dielectric composites (APDCs) were fabricated using blends of PEI and PAI.

- Microphase separation leads to nanoscale interfacial structures and deep charge traps.

- These structures reduce leakage current and enhance high-temperature performance.

- Significant improvements observed in breakdown strength, energy density, and efficiency.

- Fabrication method is simple, scalable, and cost-effective.

Extended Summary

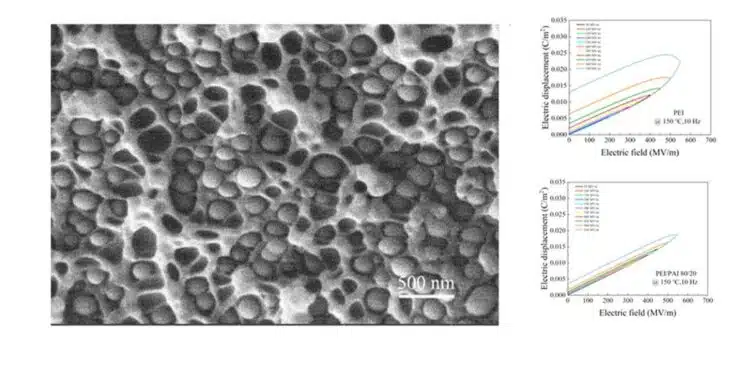

The researchers developed APDC materials by blending PEI and PAI polymers in various ratios to form thin dielectric films. Through a controlled solvent casting and thermal curing process, the blend achieved microphase separation, forming uniformly dispersed PAI domains within the PEI matrix. This nanoscale architecture created energetically favorable conditions—particularly due to mismatched electron affinities between the polymers—which induced deep charge traps at the interface.

These deep traps effectively suppressed leakage currents under high temperatures and strong electric fields, improving the overall capacitive performance. Specifically, the new composites demonstrated over a tenfold reduction in leakage current density compared to pure PEI, alongside notable enhancements in breakdown strength (Eb), discharge energy density (Ud), and efficiency (η).

To validate these improvements, the team conducted extensive characterizations using tools like FIB-SEM, TEM, FTIR, DSC, and broadband dielectric spectroscopy. The results confirmed that microphase-separated structures consistently deliver superior dielectric behavior across a wide temperature range—up to 200 °C—making them promising candidates for real-world high-temperature capacitor applications.

Notably, the fabrication process is straightforward and scalable, relying on common solvents and curing procedures, which paves the way for commercial application without added complexity or cost.

Conclusion

This study presents a compelling advance in dielectric material science by leveraging microphase separation in all-polymer composites. By strategically combining PEI and PAI, the researchers created a material that withstands high temperatures while maintaining excellent energy storage performance. Their work points to practical, scalable solutions for next-generation capacitors in demanding environments.

Read the full article:

Jinbao Chen, Ting Li, Ziyu Lv, Yongbiao Zhai, Wugang Liao, Qiyan Zhang; Enhancement of high-temperature capacitive energy storage performance in all-polymer dielectric composites via microphase separation. Appl. Phys. Lett. 7 July 2025; 127 (1): 012903. https://doi.org/10.1063/5.0280505

related link: What is a dielectric constant of polymer organic materials