Researchers from Osaka Metropolitan University introduced new 300°C heat-tolerant, high-capacity lithium supercapacitor created with solid electrolytes borrowed from all-solid-state batteries.

Capacitors are energy storage devices, consisting of two electrodes and an electrolyte, that are capable of rapid charging and discharging because of charge adsorption and desorption properties at the electrode-electrolyte interface.

Because capacitors’ energy storage does not involve chemical reactions, their storage capacity is lower than that of lithium-ion batteries, but they are useful for power levelling for renewable energy that requires repeated charging at high currents, regenerative braking energy for trains and electric or hybrid cars, as well as instantaneous voltage drop compensation devices that prevent equipment failure due to lightning strikes. They are also expected to be used to store energy for wearable devices in the near future.

Most capacitors use a liquid electrolyte with a low boiling point, which can only be used at temperatures below 80°C. Ceramic capacitors that use solid inorganic materials as a dielectric can be used at temperatures above 80°C, but their storage capacity is much lower than liquid electrolyte capacitors, which limits their use to electronic circuits. To increase the energy storage of capacitors, it is necessary to have a large contact area at the interface between the electrode and the electrolyte. Making a large contact area is difficult using solid electrolytes; so, the creation of a capacitor with high storage capacity that can also operate at high temperatures has been desired for a long time.

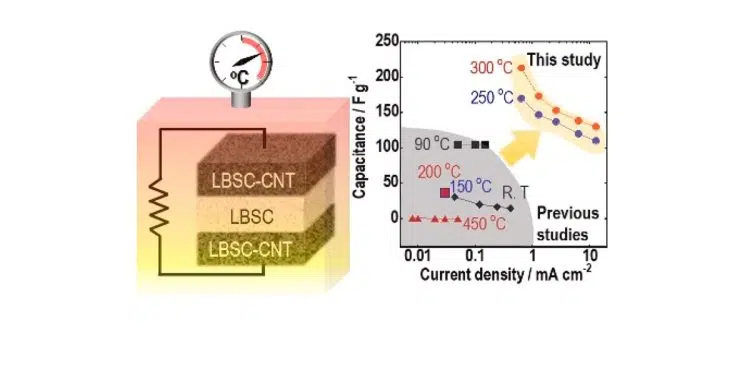

A research group led by Professor Akitoshi Hayashi at the Graduate School of Engineering, Osaka Metropolitan University, has developed a solid electrolyte that is highly deformable, allowing it to have a large contact area with an electrode, which was developed to be used for an oxide-based all-solid-state battery. In this study, they fabricated a composite using the same highly deformable solid electrolyte and carbon, then used it to construct both electrodes for a bulk-type all-solid-state supercapacitor. This capacitor is capable of high current densities and high-capacity charging and discharging at temperatures of 200-300°C, creating the world’s first bulk-type all-solid-state capacitors. The researchers expect that their capacitor will be used to improve technology for high-temperature environments, which could not be developed previously due to these technical limitations.

“The key to realizing this capacitor was to take the solid oxide electrolytes that we have been developing for all-solid-state lithium batteries—which combine excellent deformability and lithium-ion conductivity—and apply them to capacitors,” explained Professor Hayashi.

In the future, the researchers hope to construct all-solid-state hybrid capacitors with even higher energy densities, by controlling the chemical reaction between a solid electrolyte and carbon, then combining them with positive electrode materials used in lithium-ion batteries.

Abstract

The development of all-solid-state capacitors (ASSCs) based on inorganic solid electrolytes (SEs) with high thermal stability is desired. However, because of their high cell resistance, such capacitors have lower capacitances and rate capabilities than conventional electric double-layer capacitors (EDLCs) that use aqueous solutions and organic liquid electrolytes. The high resistance is caused by the mechanical and electrochemical properties of the SE. In this study, a highly deformable Li-ion conducting oxide SE was investigated to improve the electrochemical performance of ASSCs. Bulk-type symmetric ASSCs, with a 33Li3BO3·33Li2SO4·33Li2CO3 (LBSC) SE layer between two electrode layers of an LBSC-CNT composite, showed low resistance and were operable at 100–300 °C. Additionally, the highest capacitance at the highest current reported for ASSCs till date was achieved. The highly deformable SE will facilitate the design of ASSCs and expand the potential range of applications of EDLCs.

Paper Information

Title: Thermally stable bulk-type all-solid-state capacitor with a highly deformable oxide solid electrolyte

Journal: Journal of Power Sources

DOI: 10.1016/j.jpowsour.2022.231821

Author: Takashi Hakari, Syunsuke Yoshimi, Kenji Nagao, Atsushi Sakuda, Masahiro Tatsumisago, Akitoshi Hayashi

URL: https://doi.org/10.1016/j.jpowsour.2022.231821

Published: July 26, 2022

Journal of Power Sources (Elsevier website)