source: All about circuits article

STMicroelectronics offers their new microstepping motor driver that includes control logic and a power stage. Two precise sense resistors play an important role in the PWM current control—for both slow decay and mixed decay current recirculation conditions

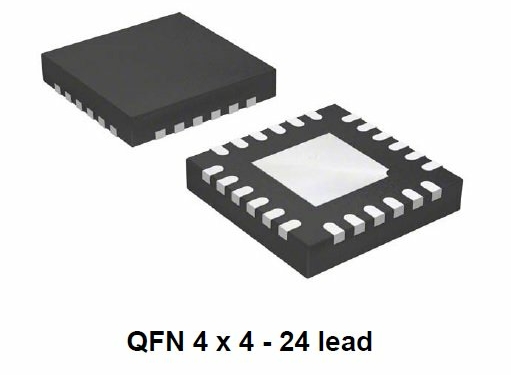

ST recently announced their new STSPIN820, which is an advanced microstepping motor driver that is capable of a stepping resolution of 1/256th of a step and integrates both the control logic and power stage in a small 24-pin QFN 4 × 4 mm package. Seems impressive.

Featured Figure 1. STSPIN820 microstepping motor driver. Image taken from the datasheet (PDF).

With a wide operating voltage range of 7 to 45 V, a host of protection features, and a low standby current of 45µA, this IC could be a good choice for applications such as 3D printers, sewing machines, and robotics.

A “Low” RDSon Value

This motor driver’s integrated power stage is advertised as having a low RDSon value (high side + low side) of 1Ω (typical). It seems to me, however, that 1Ω isn’t really all that low. In fact, in my dealings with motor drivers—granted my design experience in this regard is not exceedingly extensive—motor drivers with low RDSon values are in the range of hundreds of milliohms. So I would suggest that 1Ω might be better characterized as a typical RDSon value; if you disagree, let us know in the comments.

Figure 2. The STSPIN820’s “low” RDSon values, from the datasheet (PDF).

External Sense Resistors

As noted in the datasheet, this IC requires two external sense resistors (RSNSA and RSNSB), and because these resistors play an important role in the PWM current control—for both slow decay and mixed decay current recirculation conditions—their values must be chosen carefully. Fortunately, ST has provided values for these resistors in a typical application (see image below), and they suggest values for other external passive components. They also offer a trick for easily achieving lower resistor values with higher power ratings; this trick—though it’s probably, hopefully, common knowledge for any electrical engineer—is simply placing multiple resistors in parallel. But hey, maybe ST thought that we might forget about this technique in this particular situation…so thanks, ST, for the reminder.

Figure 3. Recommended RSENSE resistor values and other recommended values for external components. Image taken from the datasheet (PDF).

Lately I’ve noticed datasheets that don’t offer much in the way of straightforward design guidance, so it’s good to see that ST has taken the time to provide this information.

A Set of Protection Features

The STSPIN820 comes with multiple protection features. Though not exactly uncommon among high-end (or even low-end) ICs these days, these features are nonetheless important additions to a reliable, user-friendly motor driver.

- Short-circuit or overcurrent: Each power output node is protected against overload/overcurrent and short-circuit conditions, including short-to-ground, short-to-VS, and short-circuit between outputs. When an overcurrent condition occurs, the power stage is disabled and the Fault pin is driven low until the overcurrent condition is rectified (see image below).

Figure 4. Overcurrent and short-circuit protection management. Diagram taken from the datasheet (PDF).

- Undervoltage lockout (UVLO): During power up, the power stage is disabled—and the Fault pin is forced low—until the voltage on the VS pin (actually, there are two VS pins and they must be at the same voltage) rises above the VS threshold voltage (VSth(ON)), which is 6.0 V (typical). The image below shows the undervoltage lockout protection scheme.

Figure 5. Undervoltage lockout (UVLO) protection management. Diagram taken from the datasheet (PDF).

- Thermal shutdown: When the IC’s junction temperature reaches its threshold (TjSD = 160°C), the power stage is disabled and the Fault pin is driven low. Once the junction temperature retreats back to less than 120°C (which includes the thermal shutdown hysteresis value of 40°C), the fault condition is removed (see the image below).

Figure 6. Thermal shutdown protection management. Diagram taken from the datasheet (PDF).

The Microstepping Sequencer

For this device, ST uses three Mode inputs for achieving a stepping range from full-step to 1/256th of a step. As shown in the image below, each of the three mode settings (MODE1, MODE2, and MODE3) are clocked in on the rising edge of STCK (step clock input). And to allow for a very quick stepper motor response, the three mode settings can be changed at any time, and these changes are applied immediately.