source: EDN article, Patrick Mannion -March 23, 2016

It seems like engineering 101, but do you actually remember the specific differences between inductive proximity, inductive displacement, and eddy-current sensors? I asked a few friends and everyone had a pretty good idea, to varying degrees, but if you aren’t immersed in the topic the nomenclature can throw you off, as they’re all reliant on eddy currents.

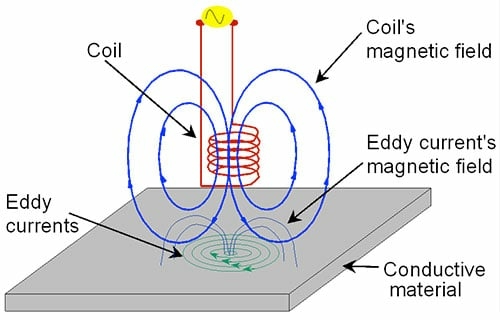

Eddy currents, also called Foucault current, are loops of electrical current induced within a conductor by a time-varying magnetic field in that conductor (Figure 1). This phenomenon of induction was first observed by Michael Faraday way back in 1831, and he summed up his experiments in Faraday’s Law. This of course states that the induced electrical current (electromotive force, or EMF) in a closed circuit is equal to the negative of the rate of change of the magnetic flux, or:

,

,

where  is the EMF and ΦB is the magnetic flux.

is the EMF and ΦB is the magnetic flux.

These combined phenomena of induction, eddy current generation, and opposition are the fundamental principles of proximity, inductive displacement, and eddy-current sensors. The primary differences are structure and the accompanying electronics. So let’s start with the humble proximity sensor, the most basic embodiment and application of these principles.

The basic but well-loved proximity sensor is a binary device that simply tells whether or not a metallic object (the “target”) is present – or not. It comprises a wire coiled around a ferromagnetic core and an oscillator to generate an alternating current to create the time-varying magnetic field (Figure 2).

Inductive displacement sensors are a big step up from proximity sensors, but mostly thanks to more electronics and processing. Instead of a binary output, the classic inductive displacement sensors provide an analog output, typically via a 4-20-mA loop, that can be processed upstream to give a good idea of the target metal’s location relative to the sensor.

More advanced iterations of the inductive displacement sensor include linear variable differential transformers (LVDTs). These look similar to transformers except that the induced current in the secondary coils from the primary are dependent on the location of the target metal, which is usually a rod (Figure 3).

However, where ultimate precision and accuracy is required, that’s where eddy current sensors come in. These differ from proximity and inductive displacement sensors in that they use an air-core coil instead of a ferromagnetic core. This eliminates the magnetic losses and thermal nonlinearities associated with ferromagnetic cores, and it also gives eddy-current sensors much faster response times to resolve fast-moving targets, up to the MHz range. However, the trade-off is higher cost due to more precise manufacturing, production, and calibration to the target metal before shipping.

Note, that by dispensing with the ferromagnetic core, the magnetic field in an eddy-current (air core) sensor is not as focused, so the measurement distance, or air gap, needs to be narrower.

For accurate details on relative performance specifications, best to consult the datasheets of vendors such as Bosch, Omron, Baumer Group, Sensirion, Micro-Epsilon, and Pepprl+Fuchs.