Kemet released its new haptic passive sensor recently, but what are the haptic sensors and how are they working? The article from Kemet blog explains some basics and shed some light into it.

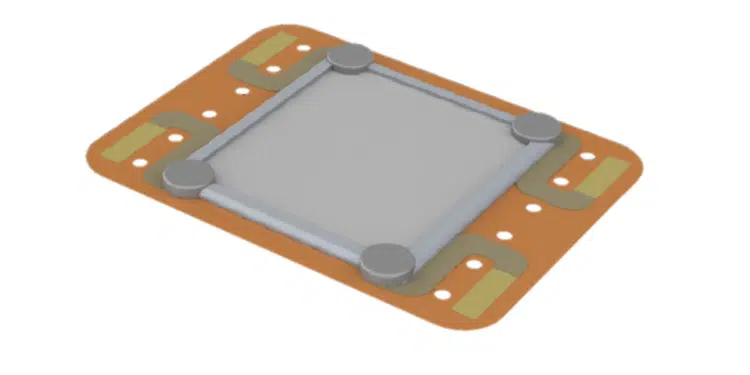

The Piezoelectric Haptic Modules (Film Flex Assembled Actuators) are revolutionary, next-generation flexible haptics actuator technology with the unique ability to provide localized, bodily sensations and tactile effects currently unavailable with any other product in the market. These versatile actuators can be used in a broad range of applications including AR/VR, gaming controllers, as well as in visionary products of the future that leverage human-computer interaction

This is made possible by the thin form factor, ideal size and flexibility of the actuators. With these Piezoelectric Haptic Modules the haptic skin technology designers can add the sense of touch to the surface of products providing localized, independent sensations that enhance user experience, natural, organic, authentic touch sensations, programmable and customizable effects providing an unique range of sensations.

Is Your Phone on Vibrate? That’s Haptics at Work.

You’re in a virtual meeting and don’t want your ringtone broadcasted over ZOOM, so you leave your phone on vibrate. Before long, you feel that light buzz from your phone and on your wrist from your smartwatch. Right after the meeting, you check your missed calls. Did you ever stop to think about the technology that makes your phone or smartwatch vibrate? That is “haptics” in action, and a basic phone vibration is just the tip of the iceberg when it comes to the different sensations possible.

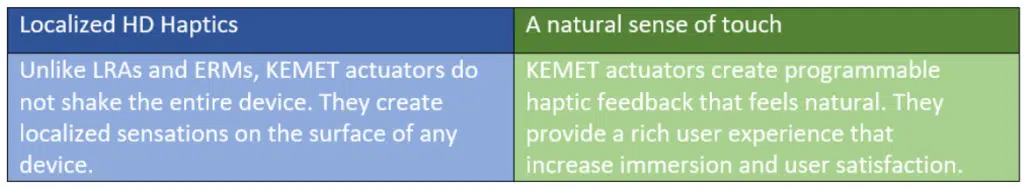

Haptics is, essentially, the science of touch when it comes to electronics. How can an electronic device enhance the user experience through interacting with the sense of touch? For example, a phone vibration is created by an eccentric rotating mass (ERM), an off-center weight at the end of a small DC motor. As the motor spins, that weight makes the device move back and forth, creating a vibration sensation. This simple technology has been around a long time and will always have a place. However, more complex haptic feedback can be found in human interface systems, like gaming systems, remote controls, and control panels, touch screens on your thermostat or home alarm system. Haptic feedback allows for more in-depth interactions with our devices using our intuitive movements and sense of touch.

What’s Next?

Inventors push the boundaries of innovation and create new devices that make the world a better, safer, more connected place to live. The latest piezoelectric polymer haptic actuator is one such invention. This new class of haptic actuators uses Electro-mechanical Polymer (EMP) technology, are paper-thin at 150 microns thick, weigh little, and provide various effective haptic outputs/sensations. The technology and the applications are endless, with a more nuanced, localized, natural-feeling experience than previous haptic devices.

Advanced Haptic Response: More Than Just a Simple Buzz

The EMP actuators can be embedded directly into a product’s surface and act as a haptic skin for devices, capable of providing localized and meaningful haptic feedback.

The wide bandwidth of the devices coupled with some physiology of touch and sensation allows for a very innovative haptic response rather than the simple on/off, buzz, or no buzz notifications associated with ERMs.

Possibilities With Piezoelectric Polymers

The EMP KEMET thin actuators are made from a unique electro-active polymer film that delivers piezoelectric effects…mimicking the sense of touch. They can convey specific material textures and familiar feelings, like the clicks and clacks of buttons, and more. In an unpowered state, the molecular structure of the film is aligned randomly. When powered, the molecules align in a direction that elongates the film, creating the piezoelectric effect.

Bonding or integrating the actuator to a rigid substrate transforms actuator elongation into an out-of-plane vibration, creating the haptic effect. Because the integrated haptic devices vibrate over a wide range of frequencies, the user experience is enhanced. Rich, low frequencies provide pleasant sensations, and then higher frequencies impart the detail and overtones, creating effects with unusually natural sensations.

Applications

EMP technology is making history by providing a sense of touch in many consumer electronic devices’ user interface.

In gaming controllers, the haptic sensation enhances the experience to a whole other level. With EMP actuators being very fast, there is no lag between the visual and haptic sensations.

In the case of AR/VR applications, the visual and audio already exist. However, the heightened sense of touch delivered via EMP actuators through various outputs allows the user to distinguish between different objects by touching them and feeling the difference.

In industrial applications, KEMET actuators combined with capacitive touch can create intuitive and easy-to-use Human Interface control systems.