To facilitate that control design, engineers require accurate and speedy current sense measurement. Monitoring power to a motor can also greatly improve system reliability, as an increase in current draw may indicate a need for maintenance long before a breakdown occurs.

The world is going electric. Thomas Edison and Nikola Tesla would be happy to see a move toward electric transportation of all kinds. Advanced battery systems are powering those vehicles, stabilizing the grid and opening many new opportunities. Engineers developing automotive systems, along with those designing industrial automation and robotics, are moving to a higher level of design with more precision motor control circuitry and more complex motion algorithms that yield better control and efficiency.

The most cost-effective and reliable method of monitoring current is the precision shunt resistor. There are two less common methods to measure current. One uses a Hall Effect sensor to measure the flux field generated by a current. While this has the advantage of low insertion loss, it is somewhat expensive and requires a rather large amount of PCB real estate. The other method, using a transformer to measure induced AC current, is also size and cost intensive, and is useful only for AC circuits.

Features

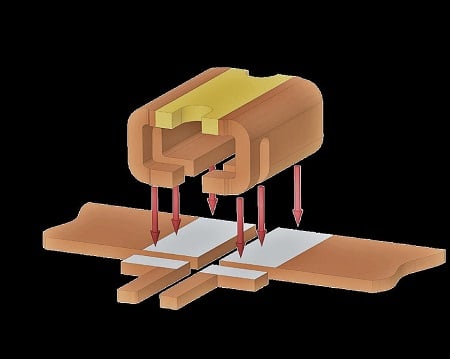

A recent introduction from Isabellenhütte (pronounced Iz-a-bell-en-HOOT-eh) is the BVN 1216 surface mount current shunt. This resistor series offers 1.0 (mΩ) or 0.5-mΩ milliohm values and features a small (4.1 x 3.1 x 1.9 millimeter) package. The four-terminal device handles 100 amperes continuously ( 0.5-mΩ version) and is available with 1 or 5 percent tolerance. Very important in this type of device is the TCR, which for the BVN is <50 parts per millions per degrees Celsius. The 0.5-mΩ version is rated at 5 watts up to 130° C — de-rated to 170° C. The 1-mΩ version is rated at 3 watts. The resistors also have very low inductance — less than 2 nano-henries (nH) — and they are AEC-Q200 qualified with reliability testing for temperature cycling, shock, vibration and moisture resistance. Their package aids airflow around the resistive element and they can be mounted on a direct bonded copper (DBC) or insulated metal substrate (IMS) power substrates.

The very low ohmic values are obviously great for cutting power loss. A good sense amplifier will be necessary to work with the accompanying low voltages. The BVN sense resistors are often used for currents in the range of 5-80 amps, and there are a number of current sense amplifiers available that make it easy to design a full measurement circuit.

These ICs have highly matched internal resistors, which is important to minimize gain and common mode voltage errors. Current sense amplifiers usually come preconfigured to voltage gains — keeping those resistors internal. For example, the INA199 from Texas Instruments is available with gains of 50, 100 or 200. The IC can sense drops across shunts at common-mode voltages from 0.3 to 26 volts, independent of its supply voltage.

A designer can choose to sense the current on the low side of the power delivery; however, placing a resistor in the load’s path to ground means that ground is floating at a slightly higher potential than the system ground. This arrangement can cause problems with ground loops. Current sense amps need to have a high CMRR if they are used on the high side.

Since the INA199 has a low offset voltage and a Zerø-Drift architecture, it enables current sensing with full-scale drops across the shunt as low as 10 millivolts (mV). Additionally, the parts common-mode rejection ratio is 100 decibels (dB) minimum, 120 dB typical, so the errors from high-side monitoring are tolerable. Offset voltage is typically 5 microvolts (µV). Gain error is 0.03 percent typical and 1 percent maximum over a temperature of 40° C to 125° C. The ICs operate from a single +2.7 to +26-volt power supply, drawing a maximum of 100 microamperes (µA), and come in both SC70 and thin UQFN-10 packages.

One current-sensing example application is automotive power steering motor control. The steering wheel connects via a CAN or LIN bus to a microcontroller and a bidirectional brushless DC motor drive. Both the position and the torque of the steering wheel are measured. The microcontroller then drives the steering motor as necessary and uses the average current to the motor, as measured by a shunt resistor, to determine torque and a position sensor to determine steering angle.

Often, each of three phases of the BLDC motor are monitored with separate shunt resistors. Peak current to this motor can be 50 amps, and both excellent stability and low inductance are required for this shunt.

Just as in automotive, precision shunt resistors are used in motor controllers, fuel injection, ignition, lighting, water pump, transmission and locking systems.