Korean researchers published their study of “Detection and segmentation framework for defect detection on multi-layer ceramic capacitors” in ETRI Journal.

Detecting defective multi-layer ceramic capacitors (MLCCs) during the inspection stage is a crucial production task to effectively manage production yield and maintain quality.

However, this task presents two challenges: the necessity of pixel-level segmentation in high-resolution images and unexplored defect patterns. To address these challenges, this paper introduces an MLCC defect-detection framework based on deep learning with an MLCC dataset we constructed and a comprehensive analysis of MLCC images.

Our framework employs an object-detection model to identify dielectric regions in input MLCC images, followed by a semantic segmentation model to create dielectric masks for calculating the margin ratio. This approach follows the traditional inspection process but can be performed without specialized personnel. Furthermore, we generated pseudo-defect images using generative adversarial networks to obtain sufficient training data. Experiments demonstrate the effectiveness of our framework, which achieved a defect-detection accuracy of 93.1%, as revealed by an in-depth error analysis.

INTRODUCTION

Multi-layer ceramic capacitors (MLCCs) are widely used in electronic products such as mobile devices and autonomous vehicles, contributing to a growing demand. To effectively manage high-quality production yields, it is crucial to detect defective MLCCs.

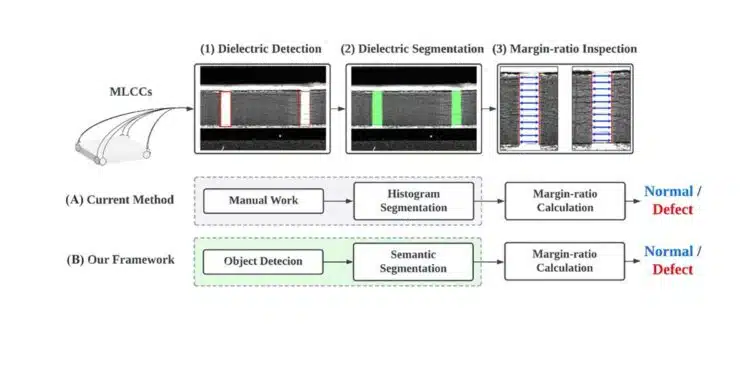

The production process encompasses an inspection stage, which examines the alignment of stacked MLCCs and identifies defects at an early stage. The inspection stage is divided into three steps: i) dielectric detection, ii) dielectric segmentation, and iii) margin inspection. An MLCC cross-sectional image is analyzed to determine the dielectric region. Subsequently, pixel-level segmentation is performed to create dielectric masks within the detected regions. Finally, the margin ratio is computed using the dielectric masks to determine whether the MLCC is defective.

Existing methods for dielectric detection rely on visual assessments and manual interventions by operators, which can reduce accuracy. In addition, histogram-based algorithms for dielectric segmentation have limitations such as the potential misidentification of patterns caused by noise and lifting. These limitations can lead to errors in detecting defective MLCCs due to inaccurate margin ratios. Recently, defect-detection methods in semiconductor manufacturing have been enhanced using deep-learning models trained on large datasets and have outperformed traditional algorithms. Representative methods employ object detection or image classification models to identify defect patterns within scanning electron microscopy (SEM) images or wafer maps, effectively eliminating the need for specialized personnel. However, MLCC defect detection remains challenging for two reasons. First, pixel-level segmentation is essential for calculating the margin ratio for each row; however, it requires extensive computations for high-resolution cross-sectional images (for example, 2048 × 2048). Therefore, an efficient method is necessary for handling high-resolution images that are continuously generated by multiple production lines. Second, MLCC defect patterns remain relatively unexplored because of the absence of benchmark or in-house datasets.

To address these challenges, this study presents an MLCC defect-detection framework that effectively interprets the inspection stage by leveraging appropriate deep-learning-based detection and segmentation models, which are trained on our constructed MLCC defect dataset. As shown in Figure 1, our framework consists of three parts. First, an object-detection model is employed to identify the dielectric regions within an MLCC cross-sectional image. Second, a semantic segmentation model is used to identify the dielectric masks within each region. Finally, the margin ratios are computed based on the identified dielectric masks. More precisely, we obtain dielectric masks by segmenting only the dielectric regions rather than the entire image. Our MLCC defect dataset, consisting of 3000 cross-sectional images, was constructed for training and evaluation. In a comprehensive analysis of the MLCC images, we identified three types of defects. However, we faced challenges in gathering sufficient defective patterns during data collection because of a shortage of defective MLCCs. It is evident that insufficient training data leads to low performance. To address this limitation, we employed pseudo-defect images generated using a generative adversarial network (GAN), which significantly enhanced performance. To the best of our knowledge, this is the first study on the detection of MLCC defects using deep learning. Our approach is distinctive in systemizing and automating the current MLCC defect-detection process. The main contributions of this study are summarized as follows:

- We propose an MLCC defect-detection framework that employs deep-learning models for object detection and semantic segmentation rather than classification, representing a pioneering effort in systemizing and automating the MLCC defect-detection process using deep learning.

- We validated the effectiveness of our framework on our MLCC defect dataset constructed through a comprehensive analysis identifying the characteristics of three distinct defect types. We leveraged a GAN to mitigate the challenges of insufficient data by generating pseudo-defect images.

CONCLUSION

This paper proposes a deep-learning-based MLCC defect-detection framework composed of dielectric detection, dielectric segmentation, and margin ratio computation.

Our framework is pioneering research in the systemization and automation of the MLCC defect-detection process that addresses the absence of public or in-house MLCC datasets.

We constructed an MLCC defect dataset of 3000 cross-sectional images for training and evaluation. To overcome the problem of insufficient training data, we generated pseudo-images with various defect patterns using a GAN.

We demonstrated the superiority of our framework through a comprehensive error analysis of our MLCC dataset. In future research, we plan to investigate additional MLCC images to uncover defect patterns and develop a unified model for dielectric detection and segmentation.

Read the full paper at the link:

Heung-Seon Oh, School of Computer Science Engineering, University of Technology and Education, Cheonan, Republic of Korea, Detection and segmentation framework for defect detection on multi-layer ceramic capacitors, https://doi.org/10.4218/etrij.2024-0066