This application note written by Sanjeevi Thirumurugesan, Vidatronic provides a brief theory on the efficiency in SC DC-DC converters and a comparative efficiency analysis between the two types of switched converter architectures using a typical application case.

Switched Capacitor (SC) DC-DC converters are DC-DC switching regulators that use only capacitors and switches to transfer charges between the input and the output. This architecture is an alternative to inductor-based DC-DC converters that provide several advantages including better on-die integration (capacitors store 10 to 100 times more energy per volume than inductors), low Electro Magnetic Interference (EMI), and lower cost. These characteristics are of particular importance in battery-operated Internet of Things (IoT) applications where devices with high efficiency, low cost, and small footprint are a necessity.

Introduction

The Switched Capacitor (SC) DC-DC converter is a DC-DC switching regulator that has been gaining popularity over LDOs and inductor-based switching convertors in applications where high efficiency is desired in a small, integrated system solution.

SC DC-DC converters use only capacitors as charge-transfer devices. The inductor-less power transfer provides multiple advantages over inductor-based switching regulators including fast transient response and reduced system size. Capacitors have better energy density and simpler, more cost-effective integration on-die in CMOS processes without additional fabrication steps. These advantages make SC DC-DC converters an attractive option for Internet of Things (IoT) applications where low cost and smaller devices are the norm.

Using only capacitors as charge transfer devices has its disadvantages as well. In inductor-based switching converters, the charge is stored and transferred in the form of inductor current which enables more efficient control of the output voltage. In SC DC-DC converters, voltage control is achieved only with a resistive loss or topology switching, which introduces increased complexity.

Supporting a wide supply range and a wide programmability of output voltages is highly desirable in IoT applications, which are predominantly battery-operated. A common case is a converter supplied by a Li-ion battery where the battery voltage can vary between 3.4 V and 4.3 V based on the charge or discharge state of the battery. Energy harvesting systems, commonly seen in IoT solutions, also involve widely varying supply voltages to the DC-DC converter.

The following sections detail how requiring DC-DC converters to operate within a wide range of input voltages and support output voltage programmability affects overall efficiency and the tradeoffs involved in achieving a higher efficiency.

Theoretical Model

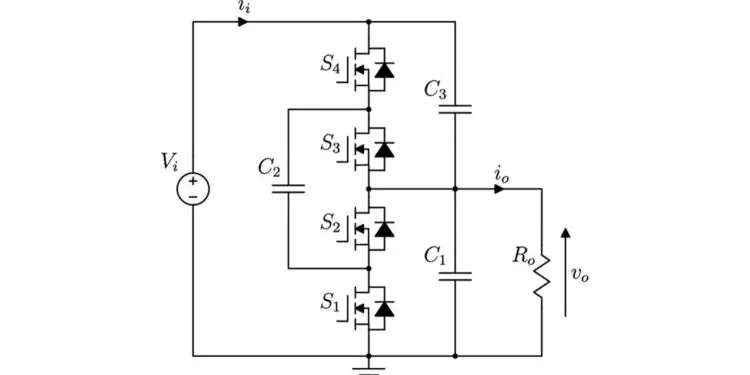

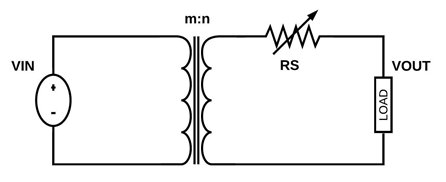

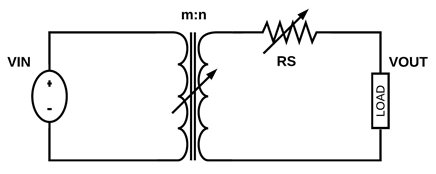

The SC DC-DC converter can be modelled as a transformer with an ideal conversion ratio and a series resistor, RS. SC DC-DC converters can be broadly classified into two types:

- In a single topology switched capacitor DC-DC converter with one conversion ratio (Figure 1), the conversion ratio is chosen so that the maximum desired VOUT/VIN is achieved (with margin for losses including parasitic capacitance, gate drive losses etc.). For other smaller voltage conversion ratio requirements, the RS is increased (by frequency, duty cycle, etc.).

- In a multiple topology switched capacitor DC-DC converter (Figure 2), the transformer ratio itself is modified by switching between topologies based on the required voltage conversion ratio.

Efficiency Comparison Between Single And Multiple Topology Converters

Single Topology Switched Capacitor DC-DC Converter

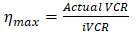

Each SC DC-DC converter topology has an ideal voltage conversion ratio (iVCR). This iVCR is the maximum ratio between the output voltage and the supply voltage of the conversion block. In practice, this iVCR is the upper bound for the actual VCR and the converter can only operate at a theoretical efficiency of 100% when this iVCR is met.

In SC DC-DC converters with a single conversion ratio of iVCR, the theoretical maximum efficiency that can be achieved is given by:

This means that for other conversion ratios required due to changes in supply and output programmability, the efficiency suffers.

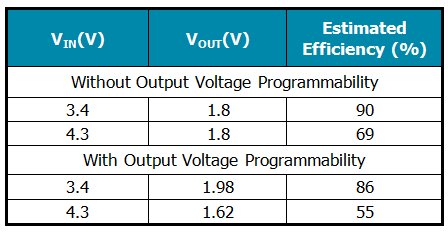

Table 1 shows estimated efficiencies of a 1.8 V nominal output single topology converter supplied by a battery with its voltage varying from 3.4 V to 4.3 V. The efficiency suffers about 20% as you move further away from iVCR towards smaller VCRs. This is worsened to about 30% in cases where the output voltage needs to be programmable as this introduces a wider range of VCRs to cover.

A 5/9 topology is chosen for the non-programmable converter and a 5/8 topology is chosen for the programmable converter in this application case.

Multiple Topology Switched Capacitor DC-DC Converter

By switching between various topologies based on the required VCR, a multiple topology SC DC-DC converter maintains better efficiency over the full range of converter supply and output voltages.

The VCR at which to switch to a different topology can be pre-determined based on the estimated drop in efficiency below a desired minimum level. Having more topologies with closely spaced iVCRs achieves higher minimum efficiency of the SC DC-DC converter.

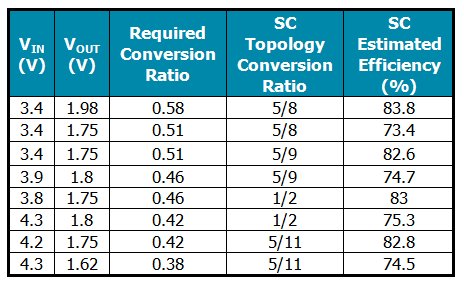

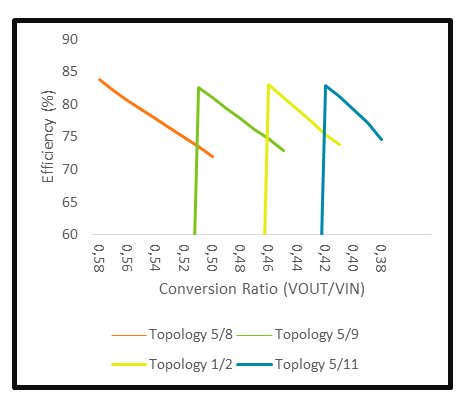

Table 2 shows estimated efficiencies for the 1.8 V output DC-DC converter using a 4-toplogy SC DC-DC converter. Figure 3 is the corresponding depiction of this architecture’s efficiency in graphical form.

Table 2. Efficiency of a multiple (4) topology switched capacitor DC-DC converter

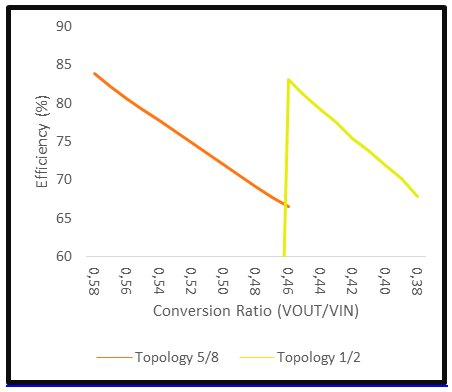

Figures 3 and 4 show the efficiency of the same system under a 4-topology and 2-topology SC DC-DC converter architecture. It is clear that quicker switching to a different iVCR topology as the required conversion ratio moves farther away from the ideal ratio for that topology helps in maintaining a higher minimum system efficiency.

Efficiency Tradeoffs

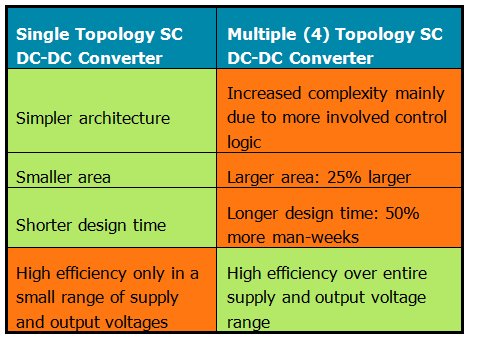

The tradeoffs to achieve this high SC DC-DC converter efficiency are the increased area due to additional switches needed for switching between multiple topologies and the control logic required to implement it. For this application case, Vidatronic estimates that the 4-toplogy SC DC-DC converter can be as much as 25% larger than a single topology SC DC-DC converter and required design resources will be about 50% higher.

Summary

Since SC DC-DC converters are a great fit for the ever-broadening array of IoT fields where battery-operated devices dominate, it is necessary to understand the efficiency tradeoffs inherent in these converters. Based on the end application’s priorities, the customer can choose between single topology SC DC-DC converters and various multiple topology SC DC-DC converter architectures.