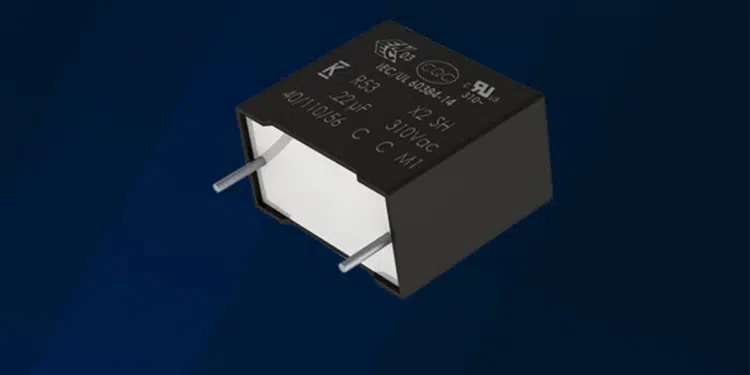

Meeting the emission requirements of regulatory agencies becomes more and more complex for the designers, and EMI suppression capacitors play a crucial role. They are required to be miniaturized, but at the same time meet high-reliability requirements under critical electrical and environmental conditions. Kemet application note shows polypropylene (PP) film capacitor (KEMET R53 series) design considerations in OBC EMI input filter as a typical application example.

One of the most enduring trends in the electronics industry is miniaturization. Power electronic designers are targeting to increase conversion efficiency by using WBG semiconductor devices. WBG devices can operate at high switching frequencies and high temperatures. Their use allows reducing the size of passive components bringing an overall more compact design and increasing power density volumes of the converters, thus making miniaturization mandatory. WBG devices also operate with extremely high voltage slew rates producing more high-frequency emissions.

If electronic components are required to be more and more miniaturized, most of the applications linked to the latest market trends face the challenge of operating under severe environmental conditions without compromising on reliability and long life.

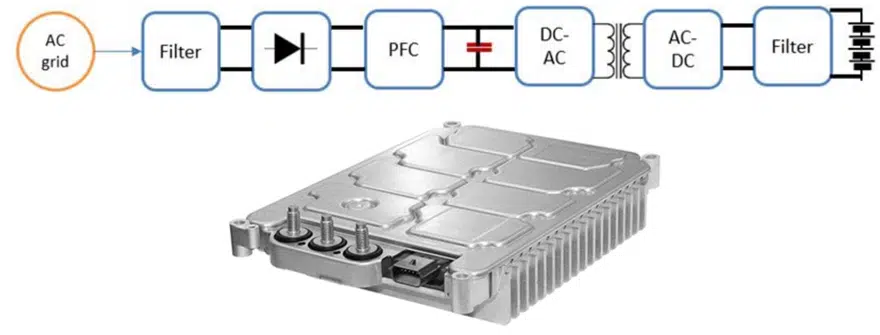

One perfect example is represented by the onboard charger (OBC) application below – see Figure 1.

Designers need to ensure that their products pass the THB evaluation. Emission certification has encountered several challenges. In some applications like the Onboard Charger, many EMI capacitors are required in the input stage to meet the emission requirements. Space is always limited in these applications, and designers are looking for miniaturized capacitors that meet the requirements of the AEC-Q200 and the THB highest grades.

PP Film Capacitors Capabilities in Harsh Environmental Conditions

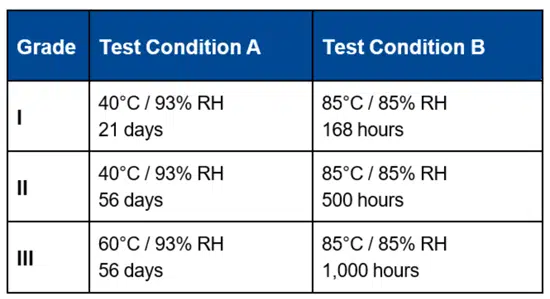

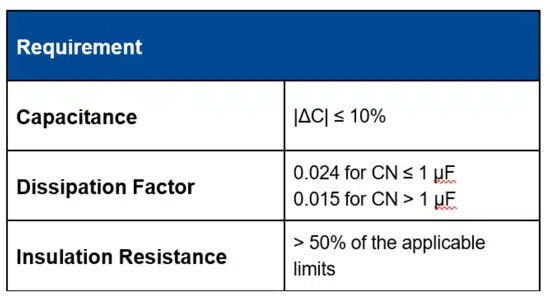

A well-accepted accelerated life test standard for active and passive components in the electronics industry is the Temperature-Humidity-Bias (THB) test, with levels of 85°C and 85% relative humidity under AC or DC bias conditions. For many years, designers in various industries (including automotive, energy, consumer, and industrial) have used this test to ascertain the reliability of their final products for up to 25 years of operation under severe climatic conditions. More recently, the THB test has been recognized as an IEC standard for EMI suppression film capacitors. The capacitor manufacturers must indicate the THB category for their certified solutions.

The table below shows the different Temperature-Humidity-Bias (THB) testing conditions per IEC Standard.

PP Film Capacitor KEMET R53 X2 series exceeds previous solutions and meets the IEC-60384-14 humidity robustness test with a Class IIIB classification. R53 achieves 1,000 hours during an accelerated life test under 85°C and 85% relative humidity at its rated AC (310 Vac) and DC (560Vdc) voltages.

Application Example

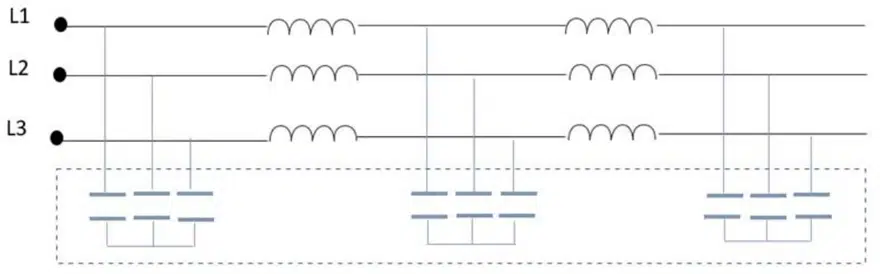

In the following example, we analyze the requirements of X2 rated capacitors for the input EMI filter of a 3-phase 11 kW OBC. The customer has designed a multi-stage input EMI filter with nine X2 capacitors – see Figure 2.

The capacitance required is 4.7 μF for every capacitor. The voltage applied across the capacitors during operation is 240 Vac at 50 Hz.During operation, the maximum ambient temperature is 100°C, and the ripple current is 2 A at a frequency of 60 kHz. Due to the high reliability required, customers need an AECQ-200 and THB Grade IIIB qualified solution. The tolerance of the capacitance is required to be ±10%. One additional requirement is a free or low halogen content solution.

Miniature metallized polypropylene film capacitor encapsulated with self-extinguishing resin, KEMET R53 X2 310 Vac series is the ideal choice for this application. More precisely, the PN R533R447000P2K meets the requirements for capacitance, tolerance and has a low halogen content.

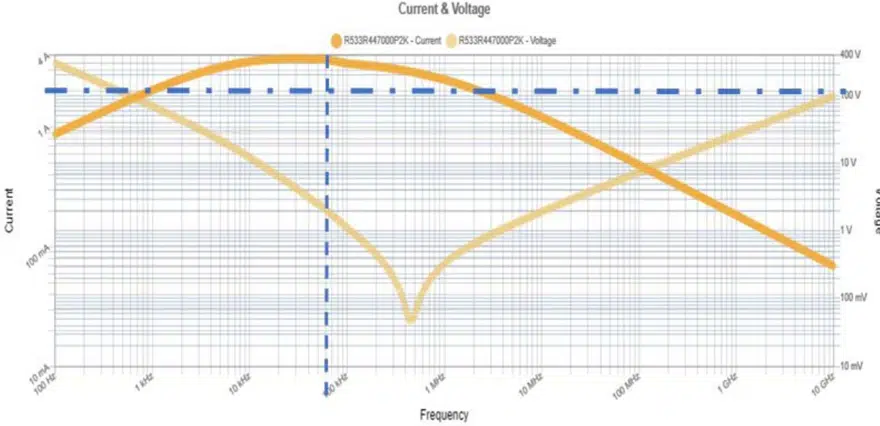

To verify the current capability of the selected solution, customers can use the KEMET online simulation tool, KSIM. The ambient temperature can be set at 100°C, as per the worst-case application scenario.

As it is visible on the KSIM Ripple Voltage and Current plot below in Figure 3., the ripple current capability of the R533R447000P2K exceeds the design’s required value of 2 A at the frequency of 60 kHz and the ambient temperature of 100°C.

Additionally, it is essential to underline that the R53 solution occupies 25% less PCB area than similar solutions from the competition.

Summary

In the above example, we analyzed how the polypropylene film capacitors – specifically the KEMET R53 series – can meet the highest THB class in a miniaturized size. These key characteristics bring significant advantages to the designers in terms of space occupation on the board. Additionally, the R53 AEC-Q200 qualification makes this series an ideal EMI suppression solution for automotive applications.