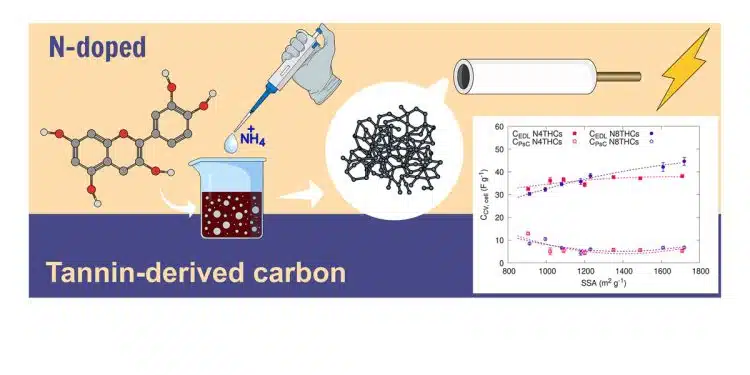

Researchers from Barrio Universitario, Chile published their study of supercapacitor N-doped carbon electrode enhancement by hydrothermal treatment in ammonia in Journal of Power Sources.

Abstract

This study demonstrates that ammonia concentration when doping carbons using hydrothermal treatment has crucial impact on textural properties. The latter translates into an improvement of the electrochemical performance of carbon materials, when used into electrochemical capacitors, especially at high-rate performance.

Nitrogen-doped carbons were synthesized by subjecting tannin to hydrothermal carbonization in ammonia solutions of varying concentrations. After carbonization and CO2 activation, the as-produced activated carbons (ACs) were tested as electrodes for electrochemical capacitors in symmetric configuration using 1 M H2SO4 as aqueous electrolyte. Interestingly, ammonia concentration during the hydrothermal synthesis step did not significantly affect the final N content (ca. 3 and 4 at. %) nor the nitrogen and oxygen functionalities on the surface.

However, the use of ammonia had crucial impact on the textural properties developed by CO2 activation, and therefore on the electrochemical performance of the ACs. The best-performing N-doped AC showed specific electrode capacitance values, based on carbon material, of 212 F g−1 at 0.5 A g−1 and outstanding capacitance retention of ca. 71 % at 40 A g−1. It also showed high cycling stability, with capacitance retention of ca. 96 % after 30,000 cycles. Furthermore, this AC outperformed similar reported materials, achieving a specific energy of 4.6 W h kg−1 at 12.1 kW kg−1.

Introduction

The increasing use of renewable energy sources, the rise of electromobility, and the advances in the development of wireless devices used in our daily lives have significantly contributed to the growing demand for efficient energy storage systems. Among these, electrochemical energy systems, such as batteries and electrochemical capacitors (ECs) have emerged as key components [[1], [2], [3]]. While batteries store energy by means of chemical reactions involving the transformation of chemical bonds through electrochemical redox reactions, ECs store charge by a physical process, namely the accumulation of electrostatic charge at the electrode/electrolyte interface [4,5]. As a result, the EC storage process is rapid and highly reversible, as it involves no chemical or phase change. Consequently, the charge/discharge cycle can be repeated over a long period with minimal impact on the performance of the electric device. Therefore, a major advantage of ECs is their extended lifespan, as they can withstand up to 20,000 charge-discharge cycles with a minor drop of less than 10 % in terms of performance retention. In contrast, batteries have a lifespan ranging from 500 to 3000 cycles [6]. However, ECs suffer from a notable drawback: their low specific energy, which prevents them from storing large quantities of electrochemical energy when compared with batteries.

Since the early 2000s, the scientific community has devoted increasing efforts to improve the specific energy and power of ECs [1,7]. The forefront of research and development in this field has witnessed the adoption of several key approaches, namely: (i) tailoring the structure of electrode materials to optimize ion transport and adsorption according to electrolyte properties [8,9]; (ii) widening the potential window of the working cell using novel electrolytes [10,11]; and (iii) incorporating specific electroactive molecules to introduce redox contributions [12,13].

In this context, activated carbons (ACs) have been widely used as the main material for EC electrodes due to their ability to be tailored in terms of porosity and surface chemistry to meet specific requirements [14]. In addition, ACs can be synthesized from a variety of raw materials, including, but not limiting to, coals, petroleum coke, polymeric materials, and various forms of raw or waste biomass [[15], [16], [17], [18]]. In particular, tannins, based on polyphenolic compounds often extracted from tree bark, have proven to be excellent precursors for the development of carbon-based electrodes for ECs [9,[19], [20], [21], [22], [23]]. Tannins indeed possess an excellent carbon yield, about 45 %, and an inherent ability for auto-condensation reactions, making them an attractive option for the production of high value-added materials [23,24]. Furthermore, the presence of –OH groups enables high reactivity, allowing the incorporation of other atoms or functionalities [22,25]. In this context, the amination of tannins using ammonia by hydrothermal carbonization (HTC) has been explored to achieve in situ N-doping [26].

Considering the amination of a single hydroxyl group in the flavonoid unit, the N content of tannin-derived materials should be 4.8 wt% [25,26]. It is expected that tannin amination can proceed beyond the usual stoichiometry by subjecting it to an HTC process using concentrated ammonia solutions. However, most research using ammonia during the HTC step does not vary the ammonia concentration. On the other hand, to obtain optimal performance in ECs [27], the obtained materials need to be activated either by chemical activation (e.g. using KOH) or by physical activation (e.g. using CO2). While the former results in ACs with higher surface areas [28], the latter enhances wettability and pore connectivity, leading to ECs with superior performance, particularly for high-power applications [29].

In this study, we focused on the synthesis of N-doped ACs derived from pine bark tannins, using ammonia solutions as hydrothermal medium. The resulting hydrochars were then carbonized and were physically activated using CO2. This study is mainly concerned with the influence of N content on the textural and chemical surface properties after CO2 activation and, ultimately, on their performance as electrodes for ECs.

Synthesis of carbon materials

Ammonia solution (NH4OH, 26.2 wt % in water, Merck), sulfuric acid (H2SO4 1 M aqueous solution, Sigma Aldrich), polytetrafluoroethylene (PTFE, 60 wt % suspension in water, Aldrich), carbon black powder (Sigma Aldrich), and glass fiber separator were used as received.

Tannins were obtained by water-ethanol extraction of Pinus Radiata bark from Chile [30]. They were dried, ground and sieved to obtain a roughly unimodal particle size distribution. In a first step, the tannins were subjected to HTC.

Chemical composition

The chemical composition of the ACs in the bulk and on the surface of the materials was obtained by elemental analysis and XPS, respectively. Table S1 in supplementary material (SM) shows a summary of these results as a function of the burn-off (BO) used to obtain each AC. Elemental analysis of the materials revealed some notable features with increasing BO. For instance, the use of ammonia during the HTC step resulted in the incorporation of a very similar N content, 4.6 and 4.8 wt% in N4THC

Conclusion

This study shows that nitrogen doping by hydrohermal carbonization in ammonia not only changed the surface chemistry of the resulting carbon materials but also improved their textural properties after CO2 activation.

These changes enhanced the electrochemical performance of the N-doped activated carbons (ACs) when used as supercapacitor electrodes. The concentration of ammonia used had no significant impact on the N content nor the nature of the surface chemistry of the carbon materials.

Read the Full Paper:

Oscar Pinto-Burgos at col., Enhancing electrochemical capacitor performance of N-doped tannin-derived carbons by hydrothermal treatment in ammonia; https://doi.org/10.1016/j.jpowsour.2024.234332