Source: Nanoramic Laboratories news

As FastCAP expands its product lines to include advanced materials from carbon nanotubes, the company rebrands to Nanoramic Laboratories.

BOSTON, MA, May 24, 2018 — FastCAP Systems Corporation, an industry leader in extreme environment energy storage technology, is rebranding to Nanoramic Laboratories. In addition to ultracapacitors, Nanoramic will specialize in advanced material solutions based on nanocarbon technology.

In 2018, FastCAP’s product offerings expanded to include a division focused on the development of advanced materials, with products as diverse as thermal interface materials, battery and capacitor electrodes, and EMI/RFI shielding technology. The name FastCAP Systems no longer represents the company’s full suite of product offerings. The shift in focus led executives to make the change from FastCAP Systems to Nanoramic Laboratories.

“By re-identifying our business around our core competencies in advanced materials, we are recognizing the broader market opportunities for our nanocarbon and composite material products. These technologies are enablers for a host of energy storage technologies, thermal management and EMI shielding solutions, as well as light-weighting and structural materials to name a few,” said John Cooley, President and Chief Operating Officer. “This, combined with overwhelming customer draw, has created a compelling opportunity to enter new and exciting markets while continuing to support our existing energy storage products.”

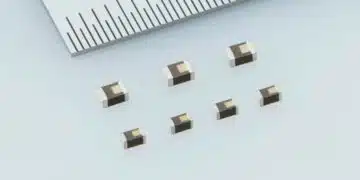

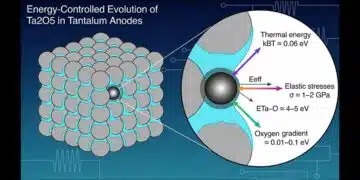

Nanoramic’s breakthrough product offering is a binder-free composite energy storage electrode initially designed for high temperature and high voltage ultracapacitors, also known as supercapacitors or electric double layer capacitors (EDLCs). This binder-free feature allows for low ESR, high capacitance, and high electrochemical stability in the same electrode. The electrode is capable of wide temperature operation, with the ability to perform in conditions between -55ºC and 200ºC. Its high operating voltage greater than 3V and high capacity retention make it superior to incumbent technology.

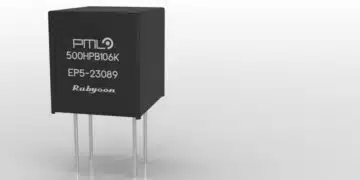

Nanoramic’s line of ultracapacitors will be sold under the name FastCAP Ultracapacitors. FastCAP Ultracapacitors are the only ultracapacitors capable of operation in conditions up to 150ºC. In fact, Nanoramic’s success in advanced material product development can be attributed to FastCAP Ultracapacitors’ years of research and expertise in developing carbon nanotube based electrodes. FastCAP’s newest technology is a reflowable, slim profile, low-ESR ultracapacitor, that provides power loss protection in SSD and IOT technologies.

About Nanoramic:

Nanoramic specializes in material solutions based on nano-carbons. Nano-carbons have exceptional electrical, thermal and mechanical properties at the nano-scale level. We synthesize and incorporate nano-carbons in various materials and transfer these properties at the macroscale level, addressing the needs of several applications. Nanoramic’s ultracapacitor division, FastCAP Ultracapacitors, is an industry leader in harsh environment energy storage, producing the only ultracapacitors capable of operating in temperatures up to 150ºC and under conditions of high shock and vibration.