This article by Verena Özdemir, Product Engineer for Capacitors at Murata Electronics provide insight how high voltage MLCC ceramic capacitors answers the growing needs for efficiency in power converters.

Power electronics are being pushed to operate faster, smaller, and more efficiently – often under more demanding conditions than ever before. Whether in the context of electrified vehicles (EVs), industrial drives or renewable energy systems, the same design pressures continue to dominate: higher power density, elevated switching frequencies, compliance with stringent safety standards, and ongoing pressure to reduce board space and part count.

These shifting expectations are not only placing greater stress on active devices but also redefining the requirements for passive components. Multilayer ceramic capacitors (MLCCs), particularly in safety and transient suppression roles, are critical to controlling voltage overshoot, reducing electromagnetic interference (EMI), maintaining insulation integrity, and improving overall system reliability.

As applications such as EV powertrains or renewable inverter strings adopt higher voltage levels in pursuit of improved power densities and elevated efficiency, capacitors must offer a new level of performance – combining electrical robustness with mechanical stability and miniaturized packaging.

Within this article from Murata Manufacturing, we examine the market forces shaping ceramic capacitor technology and its adaptation to current demands, particularly focusing on snubber capacitors and Y-class MLCC safety capacitors in high-voltage, high-speed applications.

Increasing Challenges in High-Voltage Power Conversion

The rapid electrification of transport, industry, and energy infrastructure is driving an unprecedented expansion in power conversion applications. From traction inverters in electric vehicles (EVs) to photovoltaic (PV) inverters, on-board chargers, data center power supplies, and motor control systems, the number and diversity of use cases demanding compact, high-performance passive components is steadily growing.

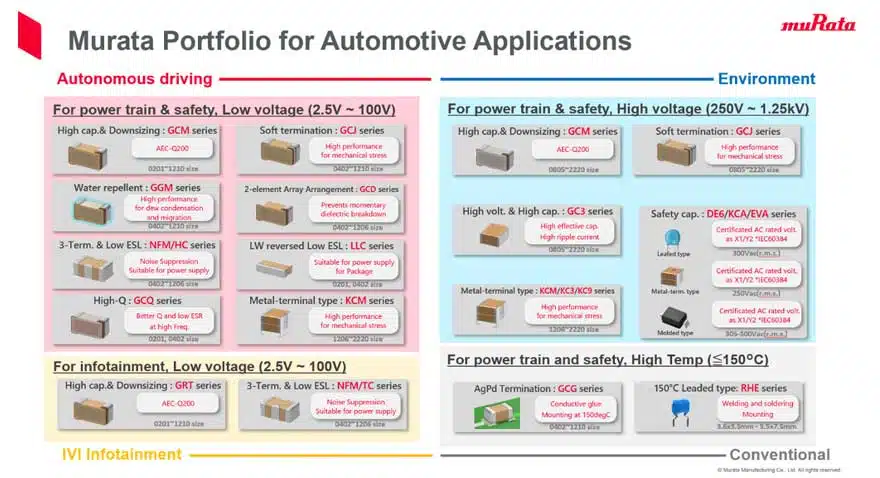

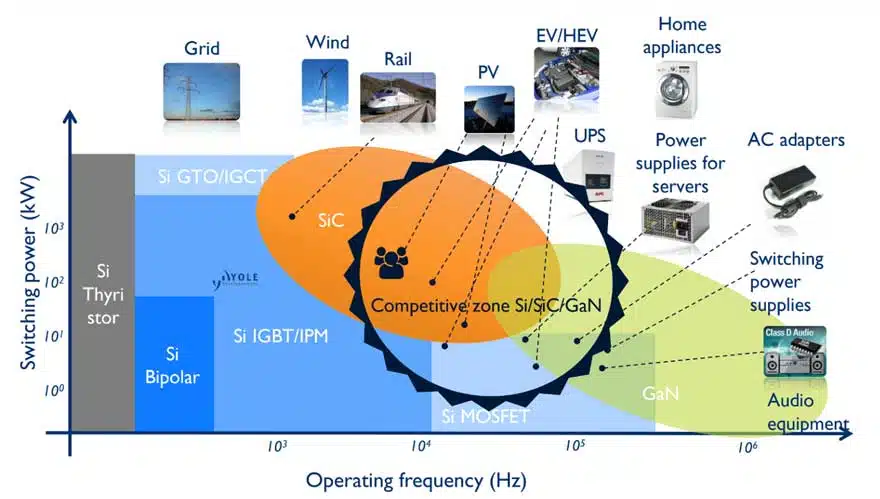

This evolution is exposing designers to a far wider spectrum of operating conditions. In particular, the increasing adoption of wide-bandgap (WBG) semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) is introducing significantly higher switching frequencies. Together, these application trends and semiconductor innovations place renewed emphasis on selecting MLCCs not only by voltage class, but also with close regard to the operating frequency and specific architectural demands of each system.

Performance improvements in power conversion are increasingly achieved through the adoption of wide bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN). These devices enable higher switching frequencies and increased voltage levels, reducing system size and boosting power density. For instance, EV battery systems are transitioning to 800V architectures with accompanying power electronics operating above 1kV to support fast charging. Likewise, the growth of decentralized renewable energy systems and compact industrial motors drives the adoption of high-speed, high-voltage topologies.

However, these conditions introduce several technical challenges. Higher switching speeds result in sharp voltage transients and electromagnetic interference (EMI), while increased voltages place strict demands on insulation and overall reliability.

Capacitors serve a critical role, suppressing high-frequency noise, absorbing transient spikes, and protecting semiconductor devices from overvoltage stress. Therefore, the advancement of MLCCs must align with these changing performance standards, necessitating enhancements in dielectric compositions and creative packaging approaches.

The Role of Snubber and Y Capacitors in High-Stress Environments

As power conversion systems push the boundaries of efficiency with higher switching frequencies and rising voltage levels, the role of MLCCs becomes even more critical. In these modern applications, conventional capacitors must evolve to address the transient phenomena, EMI, and insulation challenges created by rapid switching and elevated operational voltages, while ensuring compact packaging.

Murata’s advanced MLCC technologies are designed for a wide range of deployments, including both snubber capacitor and Y safety capacitor implementations, and tackle today’s engineering challenges head on — ensuring circuit stability, protecting semiconductor devices, and sustaining overall system reliability.

Snubber Capacitors for Switching Transient Suppression

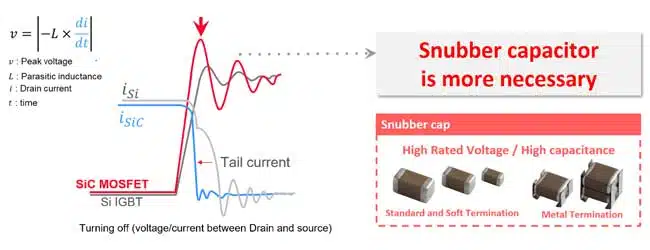

Snubber capacitors are essential in power electronics where high-speed switching induces voltage overshoot and ringing, particularly during turn-off transitions of MOSFETs or IGBTs. These effects, caused by parasitic inductance and capacitance in the circuit, can damage semiconductors or reduce their lifetime. This issue, while already present in silicon IGBTs, is further heightened in SiC and GaN power semiconductors, which exhibit greater surge voltages.

A well-matched snubber capacitor absorbs transient energy, suppresses peak voltages, and damps oscillations. Murata’s metal-termination MLCCs—such as the KC3 and KC9 series—are specifically optimized for use as snubber capacitors in SiC-based circuits.

KC3/KC9 series devices exhibit high effective capacitance and are engineered for use in circuits subject to high dv/dt stress, such as SiC-based traction inverters or on-board chargers. Their compact 2220 case sizes (5.7mm x 5.0mm) with high capacitance values (up to 2.2µF) and rated voltages up to 1250Vdc allow them to be positioned physically close to switching devices, minimizing inductive path length and enhancing suppression of voltage spikes.

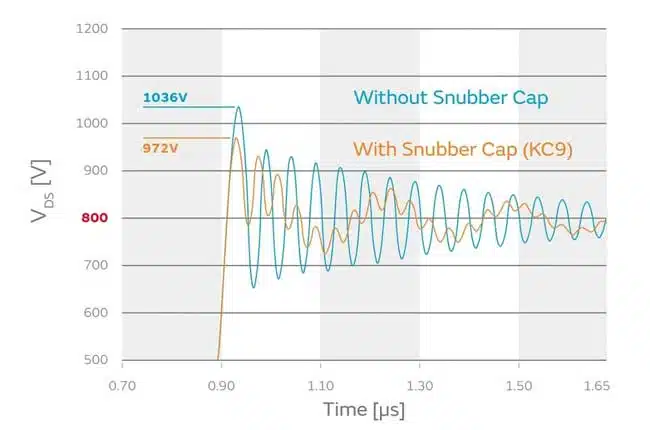

Murata’s testing, utilizing double-pulse evaluation setups with typical 800V SiC configurations, demonstrates the KC3/KC9 series’ capability to mitigate VDS surge, reducing it from 1036V down to 972V.

In applications such as EVs, the KC3/KC9 provide enhanced control over switching events, helping to improve power conversion efficiency and minimizing energy losses, even at high temperatures.

Furthermore, the surface-mount device (SMD) configuration with external electrodes, thin dielectric layers and multi-layer stacking techniques provide high capacitance density while maintaining reliability under thermal and mechanical stress. This means the KC3/KC9 also offer superior resistance to vibration and thermal cycling, exceptionally high breakdown voltages and predictable damping, making them ideal for use in demanding high-voltage power modules in automotive and industrial deployments. The KC3/KC9 series are typically placed close to the switching devices on the PCB, where their ability to suppress transients and manage EMI at the source is most effective—contributing directly to the reliability and efficiency of the overall power module.

Y Capacitors for Noise Suppression and Safety Compliance

Y safety capacitors are also vital components in power electronics, addressing the challenge of high-frequency noise and ensuring robust isolation between the primary circuitry and chassis or earth/ground. In systems where rapid switching in SiC and GaN devices generates significant EMI, these EMI filtering capacitors play an indispensable role in filtering high-frequency disturbances and limiting leakage currents during both steady-state and transient conditions. This capability is critical in applications that must adhere to stringent safety standards, where the integrity of the isolation barrier is paramount to preventing electrical shock hazards.

Murata’s Y-class capacitors are available in a range of package designs tailored to different applications and safety requirements – such as IEC 60384-14, UL 1414, or CQC. The offerings include traditional through-hole devices, as well as SMD MLCCs and both inside and outside bending resin molded SMD variants that provide increased creepage distances for high-voltage applications.

Each capacitor is engineered to deliver low dielectric loss and high insulation resistance while being certified to meet Y1 or Y2 classifications, with rated voltages reaching up to 1500Vdc. These devices are particularly relevant for EV systems, where compact packaging and high reliability are essential, and their low equivalent series resistance (ESR) and extremely low equivalent series inductance (ESL) ensure effective suppression of high-frequency noise even in dense power architectures.

Murata’s high-voltage Y capacitors not only deliver efficient noise suppression and ensure compliance with safety standards, but also contribute substantially to the overall efficiency and reliability of power conversion systems through their robust construction and versatile packaging. Their design, characterized by low leakage and reliable insulation, effectively addresses the electromagnetic and safety challenges inherent to high-speed, high-voltage applications, thereby providing a comprehensive solution for modern power electronics.

Meeting The Needs of High-Voltage Applications

As we have previously discussed, each application environment presents unique challenges impacting capacitor selection. Engineers must consider key parameters such as electrical performance, dielectric characteristics, form factor, mounting position, and thermal constraints – all relative to the use case. However, power system requirements differ not only between domains such as EVs or PV inverters but also across subsystems within a single application.

The type of MLCC selected—whether for snubbing, filtering, or isolation—must be matched precisely to the conditions in which it operates. Devices may need to withstand high dv/dt, suppress conducted and radiated EMI, or support insulation coordination. This makes the design and positioning of each capacitor on the PCB a critical engineering decision.

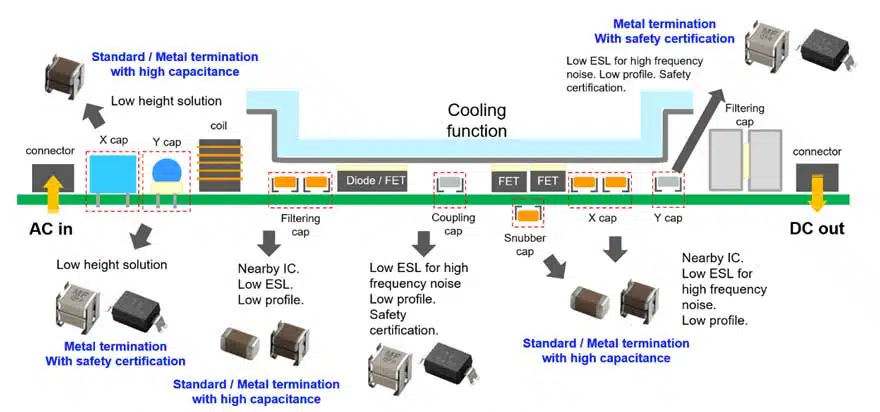

Examples of such capacitor placements and roles are shown in Figure 5, which illustrates how Murata’s components support key functions across a representative high-voltage power conversion design. The figure highlights the range of MLCC types required and underscores the importance of component-level optimization in achieving reliable, high-efficiency system performance.Beyond powertrain electronics, Murata’s automotive-grade MLCCs support a broad array of high-voltage vehicle systems.

By leveraging these capacitors, design engineers can achieve improved power module performance, streamline layout designs, and ensure a higher degree of system reliability, even under the strenuous thermal and electrical stresses typical in the EV domain.

Conclusion

As power conversion systems continue to evolve, passive components are being asked to deliver more than ever before – supporting not just fundamental circuit functionality but also helping to manage the increasingly complex trade-offs between efficiency, reliability, and miniaturization.

The demands are particularly high in automotive electrification, as moving towards higher voltages and quicker switching speeds leads to numerous fresh design obstacles, including managing transients and EMI while upholding isolation in tough conditions.

Murata’s broad range of capacitors are well suited to these needs and through careful engineering, spanning dielectric materials, mechanical robustness and package integration, its devices deliver consistent, high-voltage performance while meeting the form factor and safety expectations of today’s designs.