Source: EIN Presswire news

ROCHESTER, NY, UNITED STATES, June 11, 2018 /EINPresswire.com/ — From missiles to mines, fuzing mechanisms are used to stabilize, arm and detonate explosive weapons of all sizes. Most of these military-grade weapons are stored for years before being deployed, relying on fuze devices and batteries for safe energy storage. For more than 15 years, Ohmcraft has provided high voltage precision resistors for industry-leading designers and manufacturers of safe fuzing and ordnance-related products.

Due to the sensitive, volatile nature of the military applications in which fuzing devices are utilized, it is imperative for their resistors to be extremely reliable. Weapons of this kind can have a storage life of up to 20 years and remain stable through transport on the ground or in the air without being triggered. As such, the safing and arming of fuze devices is a top priority for engineers.

To continue to expand their portfolios of precise, reliable, and safe fuzing products, these manufacturers have long relied on Ohmcraft’s small-form, high-voltage resistors—a critical component of this type of technology—to meet their goals.

“Fuzing technology must be continuously improved in order to meet the changing requirements of current and future weapons systems,” said Eric Van Wormer, Vice President of the Ohmcraft division of Micropen Technologies. “Ohmcraft has a long history of developing resistors for use in military applications, and our engineers work closely with our clients to ensure we meet the challenging specifications of fuze design.”

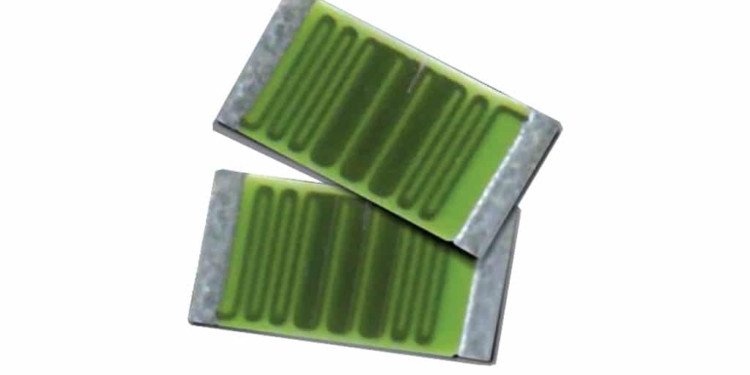

Ohmcraft’s technology utilizes the proprietary Micropen electronic printing system to print precise, narrow, serpentine lines with resistive ink on a ceramic substrate, producing higher performance resistors that can withstand high voltages.