Murata in this article explains its contributions to Sustainable Development Growth (SDG) iniative on MLCCs capacitors, which are core Murata products. Kinya Aoki from Product Engineering Department, Yukio Sanada from Business Innovation Department, and Toshiyuki Miyoshi from Materials Technology Development Department explains Murata approach to SDG.

The strengths of our MLCCs, which boast the No. 1 global share

Founded in 1944, Murata has put its corporate philosophy of contributing to cultural development into practice and has a history of supporting people’s prosperous lives.

Since the company began mass production of Japan’s first barium titanate ceramic capacitor in 1949, MLCCs have truly continued to evolve together with social and cultural development from radio in the 1940s, TV from the 1950s to the 1960s, audio-visual equipment from the 1970s to the 1980s, and PCs and mobile telephones that became widespread in the 1990s as Murata developed a wide variety of products.

Aoki: “In the history of MLCCs, which extends for more than half a century, the shift to high-functionality smartphones in the 2000s had a significant impact. This is because the number of capacitors used in devices dramatically increased. With the arrival of the 5G and 6G era in recent years, technologies including electric vehicles and automated driving are also evolving, and the demand for MLCCs is also steadily growing.

The share of Murata’s MLCCs in the global market is No. 1 in the world at about 40%. The factors behind that success are considered as follows.

Aoki: “I think that one factor is Murata’s previously cultivated history, high technical capability, and the company image of ‘when it comes to capacitors, think Murata.’ Because automotive MLCCs, etc. are products that affect human life, absolute trust and security are extremely important. Moreover, I am in charge of the task of introducing MLCC specifications to customers, so I think that exhaustively interviewing customers about their changing needs, anticipating new needs, and the ability to respond by developing products is also a factor.”

Miyoshi: “Good electronic devices come from good electronic components, and good electronic components come from good materials. This is the approach that Murata has passed down in an unbroken manner. Speaking from a materials development perspective based on that approach, I believe that the fact that Murata develops the materials to make MLCCs on its own from scratch is also a strength. Because we also build our own production facilities, this enables swift and daily work efficiency as well as production technology improvements. Such cost reduction measures ensure our superiority over competing companies.”

A long history of putting environmental load reduction into practice based on light, thin, short, and small features

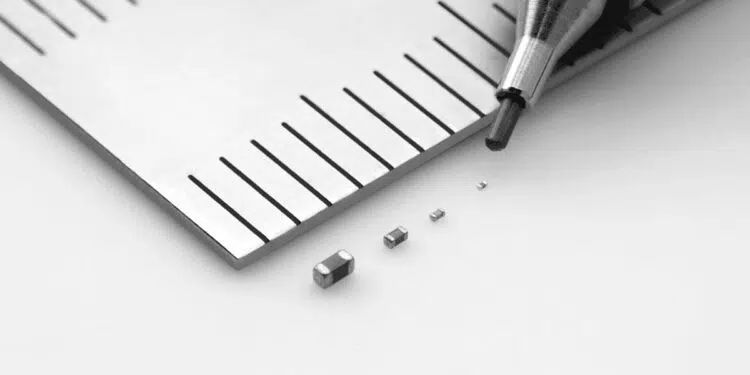

Affected by changing needs such as the shift to high-functionality smartphones, Murata developed the 0.25 × 0.125 mm MLCCs in 2012. Currently, these products have been scaled down to the point where they are difficult to see with the naked eye. Murata’s core competencies of “light, thin, short, and small” introduced in the article on “Value Creation through SDGs” reside in such products.

Aoki: “The history of MLCCs, which has pursued miniaturization to offer convenience and provide products to a wide range of markets, could also be described in a different way as a history of tackling the challenges of light, thin, short, and small characteristics. And Murata is also proud of advancing miniaturization ahead of the industry.”

Sanada: “I coordinate with other divisions while supervising work site improvements centered on the environment and sustainability. As phrases such as “SDGs” and “ESG” permeate society and corporate activities, MLCCs with their accumulated history of realizing light, thin, short, and small characteristics from the moment they were created put environmental load reduction into practice starting decades ago. Miniaturization leads to a reduction in resource use, and we are proposing new taping methods with respect to packaging materials as well as working on packaging material use reduction and waste reduction along with transportation energy labor-saving.”

MLCCs took the lead in environmental load reduction before environmental problems attracted attention.

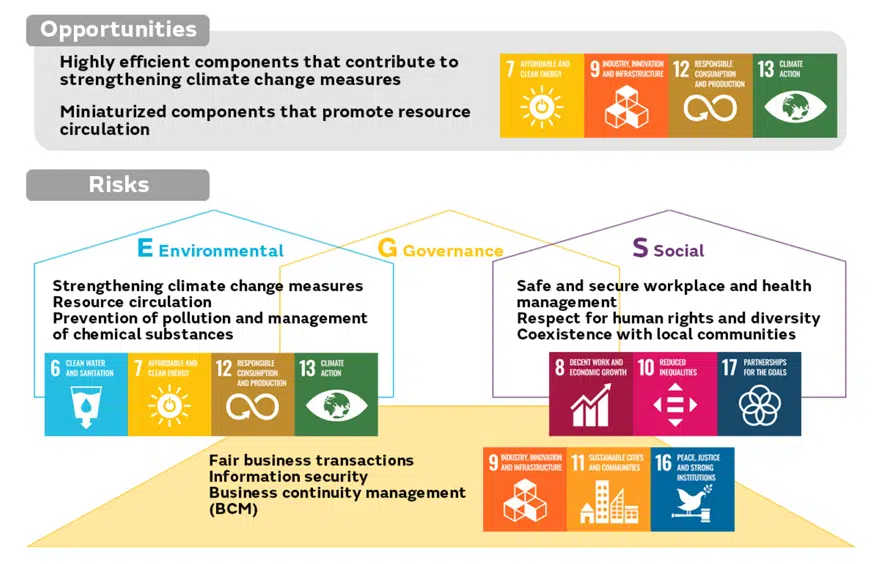

MLCC SDG Case Studies

Acceleration of initiatives through the 11 key issues and SDGs

Murata’s corporate philosophy includes the idea of “enhancing technologies and skills, applying a scientific approach,” while the corporate slogan of “Innovator in Electronics” captures the idea of “independently working in a better direction with respect to the environment and society.” Solving social issues through business is Murata’s basic policy. As a means of putting that policy into practice, we have undertaken various initiatives within MLCCs thus far.

Sanada: “Of course, there are overseas regulations such as the RoHS Directive restricting the use of specified toxic substances in electronic and electrical equipment and the REACH rules concerning chemical substance management, and we have established strict standards by combining these with Murata’s own database. While coordinating with our supply chain, internal management and screening systems have been robustly constructed to check for hazardous substances, etc.”

Miyoshi: “We are engaged in material development based on such standards and the philosophy of “applying a scientific approach,” but we have been putting an initiative to reduce waste into practice since about 20 years ago. Previously, we would start to examine ways to process waste and waste fluids in the final phase right before mass production, but we currently deal with those issues in the initial phase of development. The exchange of opinions regarding our environmental response also became lively, which I believe is due to the influence of the 11 key issues and the SDGs.”

Aoki: “Customer demands regarding the environmental response have also increased. Naturally, superior quality and cost are important, but product manufacturing that is conscious of environmental aspects will become the criteria for company selection going forward, so I would like to carefully follow this issue.”

Accumulating case studies with MLCCs and propagating SDGs throughout Murata

In addition to the miniaturization and the packaging materials reduction that we have pursued for some time already, various initiatives are advancing such as the promotion of energy conservation and smart factories based on RE100, environmental load reduction at Chinese factories, the introduction of mega solar projects, and on-site distribution using compact electric trucks.

Sanada: “Producing MLCCs involves a complex process and significant energy use, so we have been monitoring power consumption for each production process and facility for more than 20 years. However, improvements cannot be discovered through monitoring alone. Increasing data analysis accuracy after monitoring is very important. Currently, the data analysis has basically finished, so we are at the stage of setting improvement themes based on it.”

Miyoshi: “In addition to initiatives to reduce waste, we are also working in recent years to create new forms of value that change waste into valuable resources. While this is an initiative with a high degree of difficulty, I would like to approach it by first starting with the large production-scale MLCCs and then expanding to ‘All of Murata.'”

Sanada: “MLCCs have a large production scale, and their value in the market is also growing. Therefore, we would like to advance various initiatives first in MLCCs, accumulate case studies and knowledge, and then create SDG role models for ‘All of Murata.'”

Creating a fulfilling work environment in MLCCs

Naturally, we are implementing various environmental measures, but we are also promoting the goal of “decent work [fulfilling and humane work]” aimed at by the SDGs.

Miyoshi: “We are carrying out an initiative in which employees mutually share their opinions about job satisfaction and incorporate those ideas into our vision and mission. “Diversity and inclusion” activities that respect individuals regardless of gender, age, and other attributes have also permeated the company. Moreover, we are also promoting the creation of a safe and secure workplace and health management as important initiatives that will lead to ease of work.”

Sanada: “Long ago, the thinking was that corporate environmental measures were just expensive and would not generate profits. However, that is not necessarily the case. For example, energy conservation is one case that leads to improved production efficiency and cost reductions. Streamlining, quality improvement, and other activities are closely related to with environmental measures. I believe that by propagating such thinking within the company, it will help to change people’s consciousness and increase their motivation.”

Aoki: “As someone who meets with customers, I feel a sense of job satisfaction when they use many new products and from being able to provide support to solve customer issues. Moreover, I am also able to see how customers are using our products, and my role is also to provide feedback to frontline employees regarding customer opinions and impressions to increase their motivation and connect that to the creation of new forms of value.

Through such activities, I hope to contribute to social and cultural development even more than before. The times are changing, and I think that the interpretation of the expression ‘advancement of society’ in the company philosophy has changed from ‘material’ to ‘spiritual’ abundance, so I am thinking seriously about job satisfaction and ease of work.”

MLCC initiatives can also be said to be the starting point of Murata’s SDGs. The foundation of these wide-ranging initiatives has been deeply penetrated by the ideas of contributing to social and cultural development, being an ‘Innovator in Electronics,’ and other ways of thinking. The MLCC SDGs introduced in installments 1 and 2 of this series suggest how important it is to have the employees facing the same direction and acting with a common goal when promoting SDGs at the operational level.