Modern EV powertrains require effective safety protection solutions. Safety capacitors are important part of the circuit protection designs. Murata product engineers for capacitors Rina Fujiwara and Christian Merkel introduce Murata safety ceramic capacitor solutions and compare its features in this article.

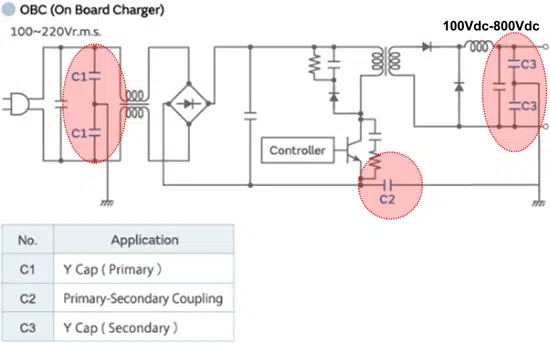

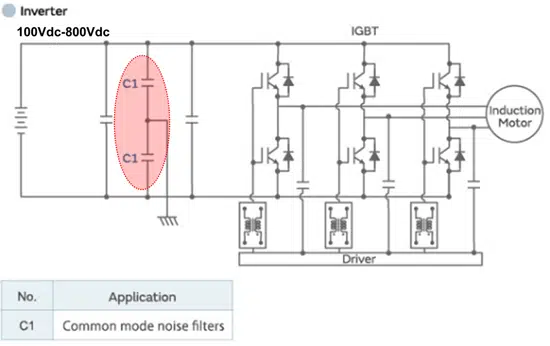

Safety capacitors can be found in on-board chargers (OBCs), traction inverters and DC-DC converters of EV powertrains, being employed for common mode filtering and isolation purposes.

Introduction

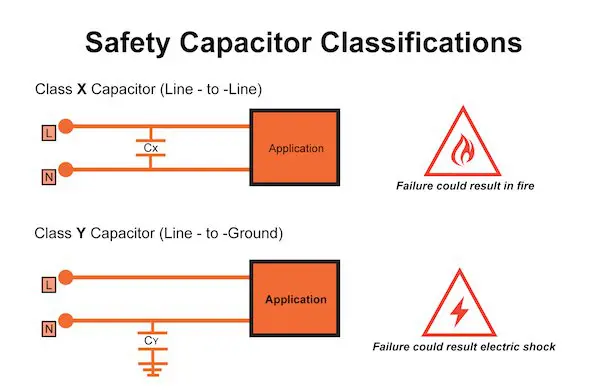

Safety rated capacitors are either across the line (class X) or line to chassis devices (class Y) that in the event of short circuit could cause fir or electric shock – as illustrated in Fig. 1.

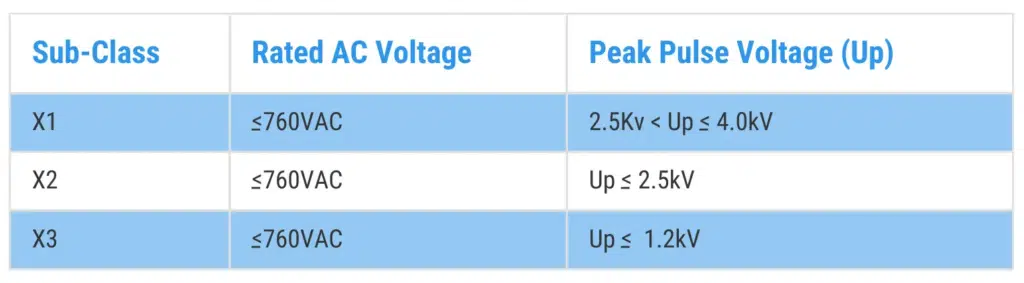

X-class capacitors are used across the line where failure would not lead to an electrical shock. X-class capacitors are divided into sub-classes by its rated and pulse voltage. See Table 1.

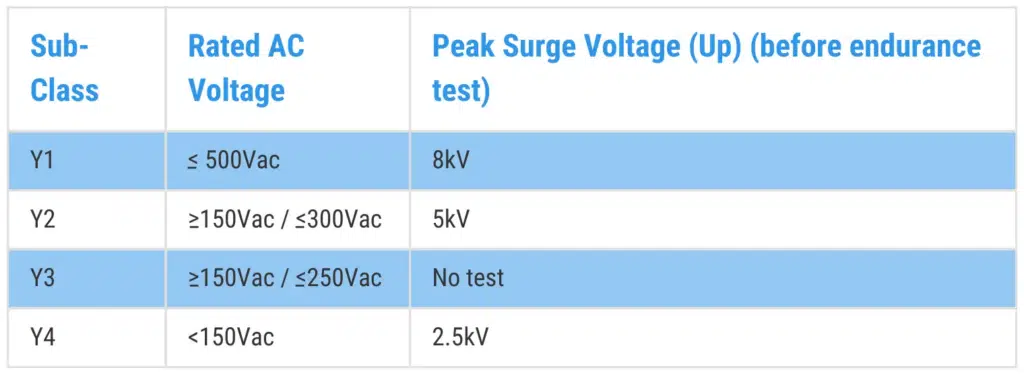

Y-class capacitors are used in “line-to-ground” applications where failure could lead to an electrical shock. It is also divided into sub-classes by their AC voltage and peak surge voltage ratings. See Table 2.

EV Powertrain Applications

Safety capacitors can be found in on-board chargers (OBCs), traction inverters and DC-DC converters of EV powertrains, being employed for common mode filtering and isolation purposes. Examples are shown in Figures 2. to 4. below.

Murata Safety Capacitor Solutions

The engineering team at Murata has been developing capacitors for the automotive sector for many decades. Drawing on this long-standing experience and access to cutting-edge technology, the company is constantly expanding IEC60384-14 Y2-compliant AEC-Q200 qualified capacitors line up that are specifically optimised for EV deployment.

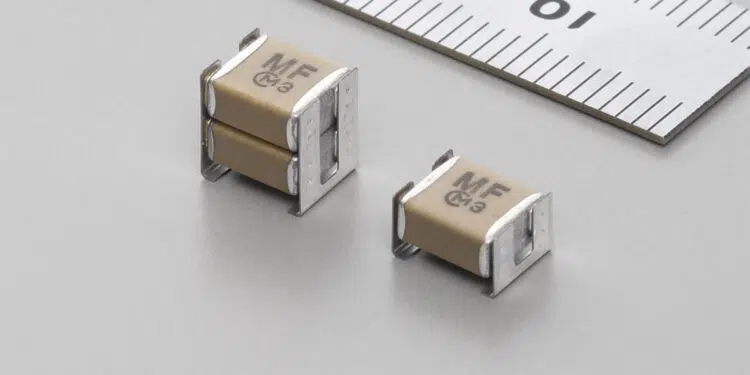

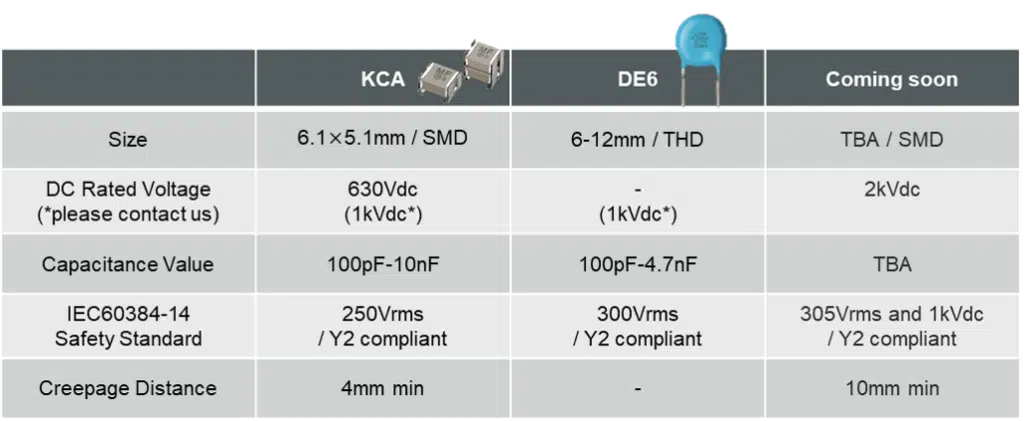

The Murata DE6 series capacitors (Figure 5.) offers a highly effective THT solution. Available in capacitance values from 100pF to 4.7nF, these 300VAC-rated Class X1/Y2 components are fully compliant with the IEC60384-14 international safety standard. They come in a though-hole packaging format with compact physical dimensions, and are capable of supporting higher temperature operation than film capacitors.

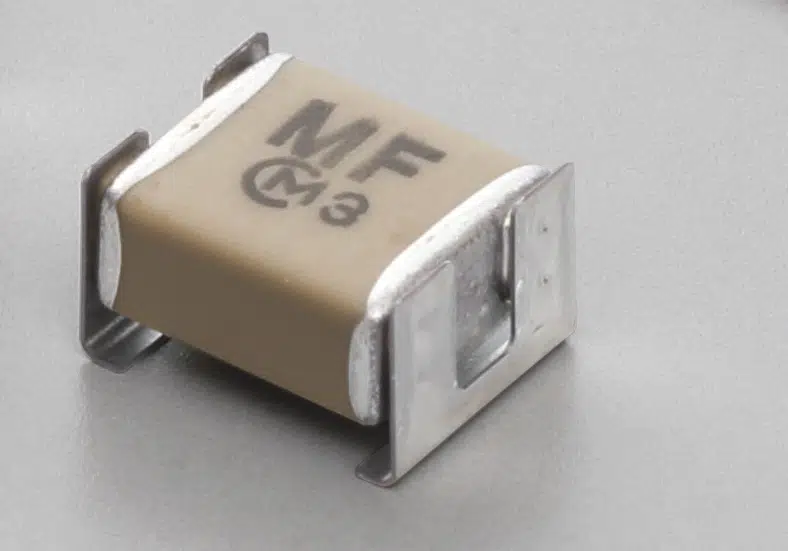

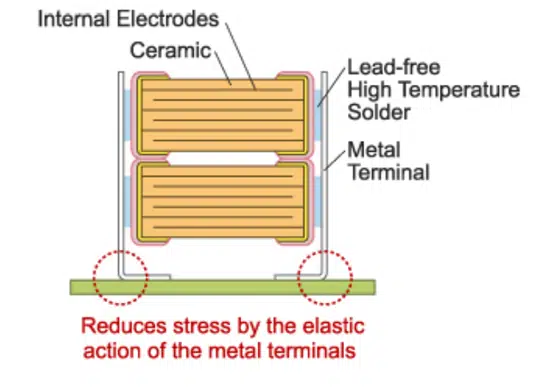

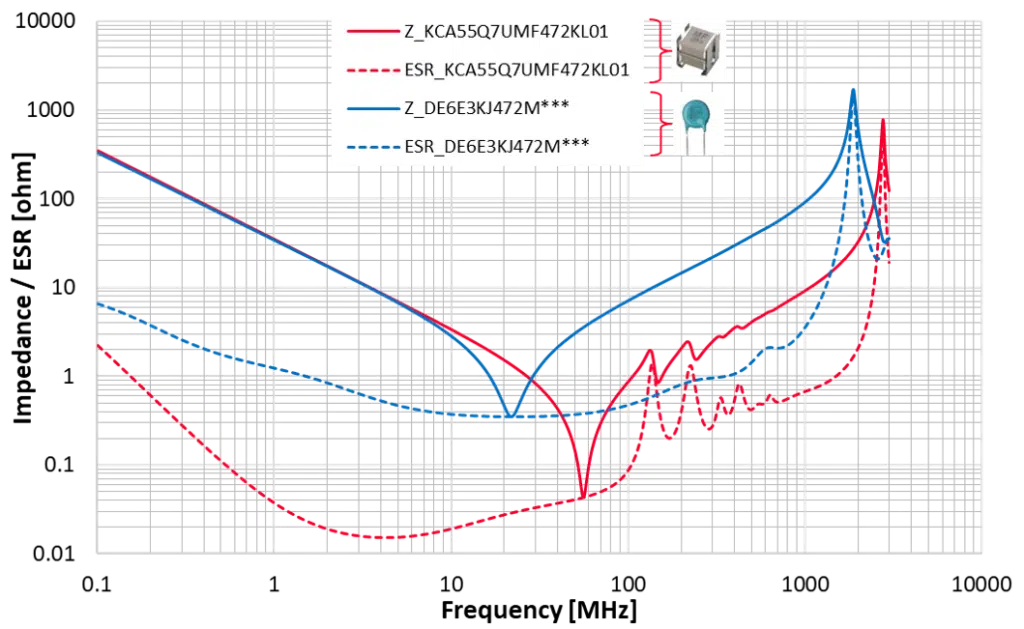

Murata’s KCA series of multi-layer ceramic capacitors (MLCCs) on Figure 6. and 7. can act as Y capacitors in DC lines (with a 1kVDC rating being supported) in addition to Y capacitors in AC lines. They have a 4mm creepage distance to prevent high voltage arcing occurring, in accordance with IEC60384-14.

The high density construction of these units means that they have significantly smaller case sizes. This allows valuable board space and headroom to be saved. Their surface-mount configuration means that they are compatible with reflow soldering – which is highly advantageous from a production perspective, as there is no need to include an extra step for them to be mounted onto the PCB. KCA series capacitors also exhibit very low equivalent series resistance (ESR) and equivalent series inductance (ESL) figures and will significantly contribute to noise suppression activities – see Figure 8.

Another major benefit of these stacked type MLCCs with metal bow construction is the elastic action of their metal terminals, which substantially reduces the stress put on the ceramic element. This product is not damaged even with a board deflection >5mm and solder cracks do not occur even with 2,000 heat cycles based on Murata test conditions (note that warranty is for 5mm and 1,000 cycles). The risk of a failure from vibration is also mitigated.

In addition to the two product series just described, Murata will be announcing a new family of 2kVDC rated MLCCs for 800V systems. These will enable higher voltage powertrains to be attended to, with 10mm creepage among their most notable features. 10mm of creepage distance will mean that IEC60384-14 requirements are met, assuming 800VDC as applied voltage. More details on this product will follow soon.

Conclusion

Safety capacitors have a vital role to play in EV systems – enabling EMI suppression, protection from voltage transients, etc. With powertrain voltages being raised while EV powertrains try to reach higher power/volume ratios and pursue elevated efficiencies, a new breed of components are going to be required.

Murata has shown that it is keeping pace with the technological progression being witnessed within the EV sector, and will continue to introduce new solutions that meet the expectations of vehicle manufacturers and their tier 1 systems integrators.

Please contact Murata or refer to Murata website for more details.