In this article Frenetic power electronics engineer Sotiris Zorbas, MSc try to identify the weak spot of 500W LLC Transformer design nad propose new construction design as a case study of transformer design optimization.

Referring to Texas Instruments application note for a 500W LLC Half bridge (PMP40379)1 power supply I started off searching through the app note to see if I could find some info about the magnetic components.

Without having a clear image about the transformer materials or the exact construction, I tried to simulate a compatible transformer to get similar results and see if we can improve the design further.

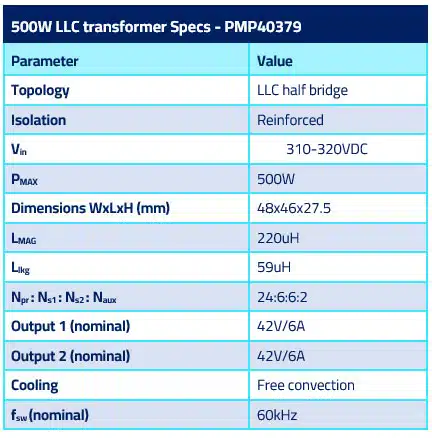

In Table 1 you can have a look at the most relevant specs for the construction of the transformer:

Transformer Thermal Simulation

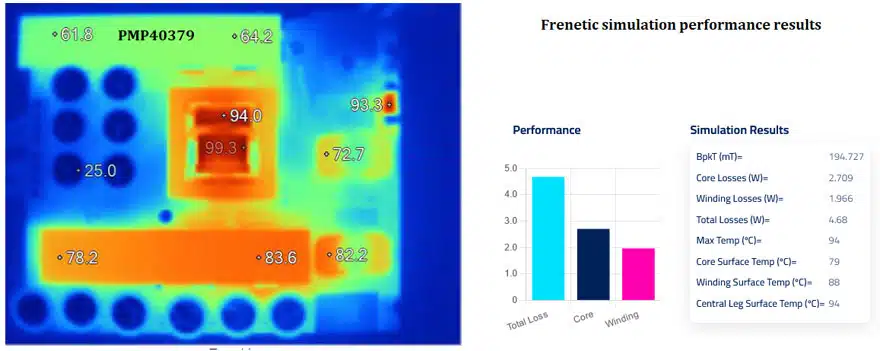

Figure 1 shows the Frenetic simulation and an actual thermal picture of the transformer for the same operating conditions.

We predict that the maximum hotspot temperature is in the center leg of the transformer at 94°C (we can’t see that in the image). The windings temperature is predicted at 88°C, while they appear to be at 94-99°C and the core surface temperature is really close to the actual one, around 78-80°C.

DISCLAIMER: The exact Litz wire dimensions and winding arrangements were unknown from the online material, so any differences in temperature can be easily explained in this case. Despite this fact, the overall temperature behavior of this design is in line with the actual transformer behavior.

The main idea of this simulation was to get as close as possible to the actual transformer built for the Texas Instruments app note, and not to optimize it! What I needed was a starting point to make iterations later.

Transformer Design Improvements

In the next step, I will focus on the weak points of this transformer, trying to improve the design and to realize a more efficient component!

Now the question is, where is the design’s weak spot? And by weak spot I mean looking at the temperature at different places on the Transformer. Focusing on the Transformer thermal image under test, we can easily notice a ~20°C difference between the temperature of the windings and the one of the core. In the simulation, which again isn’t an exact one because of the lack of data, we can come up with an observation about the hotspot location at the center leg of the Transformer.

The core losses elevate the core temperature. The skin, proximity and fringing losses elevate the temperature at the windings. But the windings and the core conduct heat between them because they are thermally coupled with the bobbin as a medium.

That said, the weak spot of many Transformer designs is usually located in the center leg. That’s the area where we don’t have any air convection, plus the fact the center leg is in contact with the bobbin, which can easily make the temperature rise even more.

Therefore, the hypothesis is that the weak spot here is the temperature of the center leg. That is not obvious in the thermal image, but it is clear in the simulation graph on the right. That might be true, but unfortunately there isn’t a way to just lower the temperature of the Transformer’s center leg.

What can we do?

- Plan A: Decrease the core losses.

- Plan B: Decrease the winding losses.

- Plan C: Decrease both the core and the winding losses.

- Plan D: Change the ratio of losses closer to 50-50, keeping the total losses (core + winding) approximately the same.

- Plan E: Change the ratio of losses closer to 50-50 and decrease the total losses.

Out of the five options, Plan E is definitely the best one, and I’ve decided this will be my approach in this case: lowering the core and the winding losses, whilst trying to keep a 50-50 balance. Seeking to list the other plans by effectiveness is debatable, and it depends on the design.

The game of conflicts

Let’s focus on the plan now. Plan E’s mission starts with lowering the core losses.

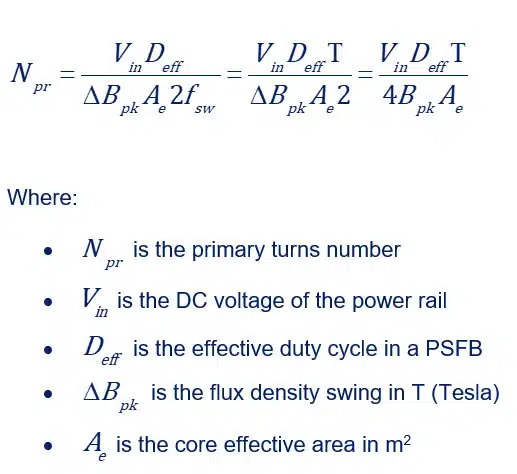

To control the flux density, we must change the number of primary/secondary turns. That means that the wire length used for the Transformer is longer, resulting in more resistance and more losses in the windings.

I aimed at increasing the number of turns to a point where core losses decrease, but not so much as to cause an abrupt increase in winding losses. How aggressively we increase the turns of the primary (and the secondary to maintain the turns ratio) is going to dictate if the winding losses will increase a lot or not.

We can see in Figure 2 that 57% of the losses are from the core, and 43% of the losses are from the winding. Although the ratio of losses isn’t that bad, the core losses by themselves (in Watts) are significant. That is supported by the fact that the peak flux density swings, which dictates that the core losses are close to 200mT. Literature suggest 100-150mT as a nice operating point. There is no reason why we cannot operate at 200-250mT whatsoever, except the fact that the core losses increase roughly at about the 2.7th power of the flux density swing.

I run the numbers going from 200mT -> 150mT and that would equate to 50-55% less core losses for the same core. But my goal is to go from 24T to 30T at the primary, which is problematic given the bobbin space that I have. Truth is, initially I went for it and changed the windings, only to realize that the space of the bobbin forced me to change the windings altogether. That increased the winding losses more than I was comfortable with, meaning that at the end the total power losses didn’t decrease so much.

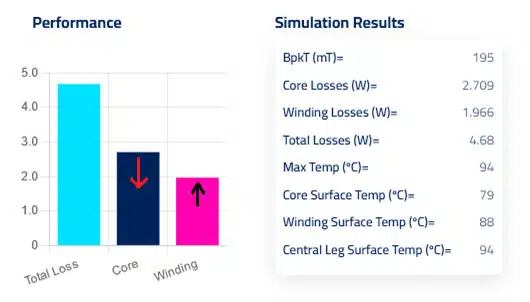

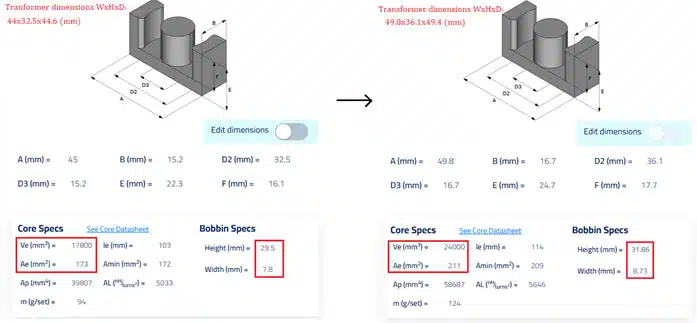

Therefore, I picked a slightly bigger core. I was lucky enough that the next standard core didn’t have much bigger dimensions, as shown in Figure 3. What it does have though is 34% higher volume and 22% more effective area (Ae) which is what we are actually interested in.

As Faraday’s simply suggests, the number of primary turns for a 22% increased Ae will decrease by 18%. In other words, we need less turns for the same operating ∆Bpk.

OLD vs NEW 500W LLC Transformer Design Performance Comparison

You can find all the Magnetics that we design in our Newsletters in the Frenetic Library section.

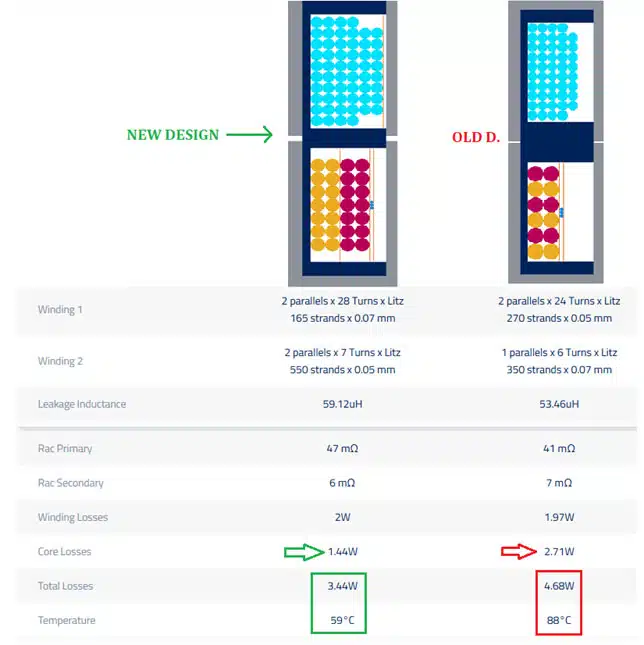

To get to the point now I choose 28T for the primary turns, that translates into 137mT of flux density swing. Given the fact that the bobbin space has increased (Figure 3) as well, I’ll give this solution a try. In Figure 4 you can see comparison between the two designs.

Conclusion

What have we achieved here in the new LLC transformer version?

- Core losses dropped by 1.27W or by 46%.

- Winding losses stayed the same!

- Total losses decreased by 26.4%

PLAN E was successfully achieved!

Moreover:

- Transformer dimensions increased only by WxHxD(mm): 6×3.5×4.8

- The hotspot temperature dropped to 59°C from 88°C (natural convection)

References

- Texas Instruments, September 2018, “500-W, Single Stage LLC Power Supply Reference Design for Audio Amplifier”, PMP40379