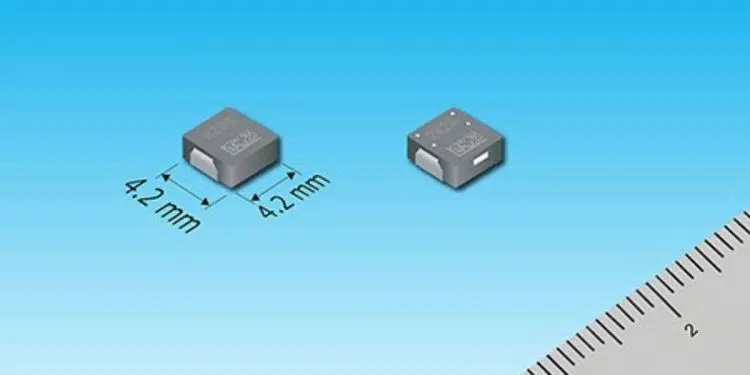

Panasonic Industry commercialize a small, robust power Inductor 4 mm by 4 mm size for automotive use. High resistance to vibrations and a redundant structure offer improved connection reliability.

Panasonic Corporation announced that its Industry Company has commercialized a small power inductor[1] (4 mm by 4 mm square) for automotive use that enables higher performance and downsizing of electronic control units (ECU) for advanced drive assistance systems (ADAS) and autonomous driving systems, with the ability to withstand harsh environment. Mass production of the power inductor will start in May 2022.

As the computerization of cars advances, ECUs are now incorporated in many cars. ADAS and autonomous driving require a number of ECUs capable of highly efficient control over cars, with such ECUs requiring small and high-performance power inductors free from connection failures.

The company has commercialized a small power inductor of 4 mm by 4 mm square for automotive use to address these needs. It is manufactured with a molding technology where the power inductor is completely filled with a melted metal composite material[2], and is highly resistant to vibrations, thereby preventing crack formation. Further, its leads have a redundant design[3] that improves the connection reliability of the coil. The improved manufacturing process has reduced CO2 emissions during the production of this product by 50% (CO2 emissions/unit).

Features:

- Suppress the bias of magnetic material density to prevent the formation of cracks inside the product.

- A connection with a redundant design between a built-in coil and a terminal improves the connection reliability.

- CO2 emissions during the manufacturing process are 50% less than in conventional cases (CO2 emissions/unit).

Applications:

ECU power circuits in cars equipped with ADAS/autonomous driving systems, radar ECUs, sensing camera ECUs, ECU power circuits in cars equipped with information communication systems, Telematics, gateways

Features Explained

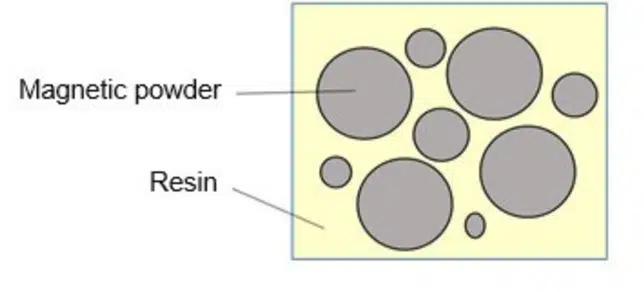

1. Suppress the bias of magnetic material density to prevent the formation of cracks inside the product.

Sealing with a metal composite material requires that the metal composite material maintain a homogeneous density during molding to prevent crack formation in the product. However, downsizing a product makes it difficult to achieve a homogeneous density, and leads to a case where, after the molding, voids are formed between metal magnetic material particles, which cause a crack. To deal with this problem, the company has developed a metal composite material for insulating magnetic powder and sealing the metal magnetic material, by devising a special resin added to the metal. This metal composite material is melted and injected into the coil to fill it thoroughly. Therefore, the company has achieved a small power inductor that suppresses crack formation in the product.

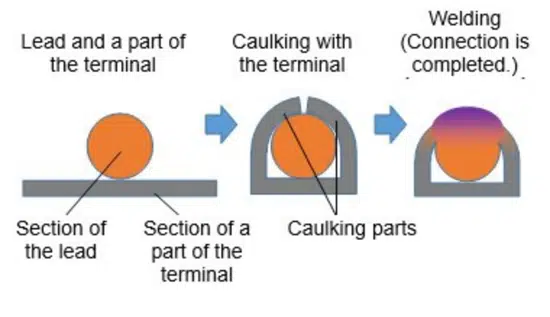

2. A connection with a redundant design between a built-in coil and a terminal improves the connection reliability.

A built-in coil has leads at both the start and end of windings, and these leads are electrically connected to a terminal inside the product. Currently, all leads have a redundant design that enables multiple connections, which prevents the occurrence of connection failures. In addition, each lead is welded to a part of the terminal in a structure where it is held in the terminal (caulking structure), which improves the connection reliability.

3. CO2 emissions during the manufacturing process are 50% less than in conventional cases (CO2 emissions/piece)

Due to its smaller size than conventional ones, the product requires finer processing and assembly, resulting in a problem whereby the conventional manufacturing process needs a greater amount of power to manufacture the product. To deal with this problem, Panasonic has changed the processing method by reducing heat treatments, thereby allowing simultaneous microfabrication and high-speed processing. This has led to a significant improvement in the productivity of the production process. As a result, CO2 emissions during the manufacturing process are now 50% less than in conventional cases (CO2 emissions/unit).

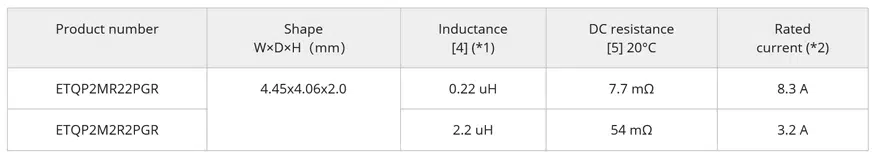

Basic specifications:

- (*1): Measured at 100 kHz. (*2): Current value that causes a temperature rise of 40degrees.

The company is planning to expand the inductance range of the power inductor to meet market needs.

Term Descriptions

[1] Power inductor. An electronic component used in DC/DC converters, etc. Functions as a filter that accumulates energy or eliminates noise.

[2] Metal composite material. A magnetic material made by insulating the powder of metal magnetic material (iron group) in which powder based on metallic magnetic material with resin.

[3] Redundant design. A design concept whereby backup means are provided for a part that must be highly reliable so that a problem with it does not develop into a major issue. A redundant design allows a product to maintain its normal functions and safety.

[4] Inductance. This is one of the indexes indicating the capability of a coil. A changing current flowing through a coil creates a voltage that generates a current flow for offsetting the changing current. The degree of creation of this voltage is referred to as inductance.

[5] DC resistance. DC resistance is a resistance component of winding (copper wire). The lower the DC resistance, the lower the power loss. Thereby yielding an improvement in power efficiency.