Research team from Jilin University in China has developed adhesive electrodes that solves one of the major issues facing advancing flexible 2D supercapacitors — optimize interface between electrodes and the electrolyte by preparation of effective adhesive electrode.

“Flexible 2D supercapacitors typically suffer from complicated and time-consuming fabrication procedures and poor mechanical endurance,” said corresponding author Wen Li, professor from Jilin University in China.

“In this study, we created a new type of all-in-one adhesive electrode that can not only simplify the fabrication process but also overcome the interfacial displacement of conventional supercapacitors.”

Flexible 2D supercapacitors are typically sandwich stacked structure or 2D flat structure. Under repeated mechanical deformation, the interface between electrodes and the electrolyte can become displaced, rendering the interfacial contact less effective.

“However, the mismatched bulk strain between the electrode and the electrolyte layers usually causes the inevitable interfacial displacement and delamination during repeated mechanical deformation, giving rise to a significant increase in the interfacial contact resistance between electrodes and electrolyte layers,” Li said.

“As a result, the charge/discharge rate is severely diminished and the energy storage performance as well as the stability are suppressed. More frustratingly, the integrated flexible supercapacitor devices in series for high-voltage output still depend on lots of conducting metal wires, which largely limit their flexibility, deformable tolerance and miniaturization for practical applications.”

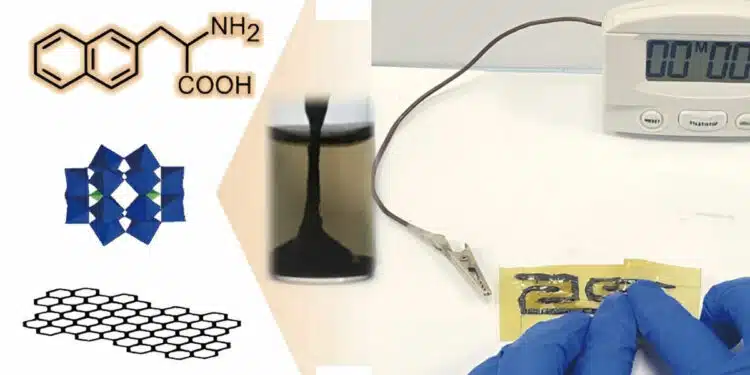

To solve interfacial problems and eliminate wires, the researchers combined HPA with amino acids and carbon materials to construct a kind of all-in-one wet adhesive simultaneously carrying electron conduction, redox property, mechanical deformation, and adhesiveness. Heteropoly acids (HPAs), serving as a class of inorganic nano-sized clusters with fast and reversible redox activity enables the supercapacitor to quickly and reliably charge and discharge energy.

The amino acids help the HPAs become more flexible, while the carbon materials contribute to electronic conduction. They patterned the resulting wet adhesive in a parallel manner to form flexible electrodes. After bridging the gap between the parallel electrodes by injecting a gel-electrolyte, they can conveniently create a flexible 2D supercapacitor.

“We found that the carbon components improved the electronic conduction; the chemistry of the amino acids contribute to the interfacial adhesion; and the HPA clusters both prevented larger structures from forming and endowed the electrode with electron transfer and storage ability,” Li said.

“The resultant adhesives are adaptive and deformable materials that facilitate the development of flexible 2D supercapacitors for high voltage output with metal-free interconnects.”

The researchers said they would try to create substrate-independent and miniature flexible 2D supercapacitors for developing implantable power devices.

More information: Chuanling Mu et al, Taming of heteropoly acids into adhesive electrodes using amino acids for the development of flexible two-dimensional supercapacitors, Polyoxometalates (2024). DOI: 10.26599/POM.2024.9140062