Indian researchers from Government College for Women, University of Kerala, Thiruvananthapuram, India have developed a method to produce activated carbon, suitable for supercapacitor fabrication from coconut husks, a major agriculture residue.

The coconut husk biowaste-derived activated carbon holds immense promise for sustainable and efficient green solutions for high-performance supercapacitors due to its availability, low cost, and eco-friendly nature.

Supercapacitors, with significantly higher capacitance and energy storage capacity than conventional capacitors, have emerged as a vital component in the quest for sustainable energy storage solutions. But, the search for an ideal supercapacitor electrode material has been a significant challenge.

The research team, led by Xavier T.S., Assistant Professor, Department of Physics and including Merin Tomy, Ganesh S.G., Anu M.A., and Sreelakshmi S.R., found the prototype supercapacitors made of coconut husk-derived activated carbon to be four-times more efficient that the existing supercapacitors.

The findings have been published in American Chemical Society’s peer-reviewed Sustainable Resource Management Journal.

The team had leveraged the innovative microwave-assisted method designed at the Centralised Common Instrumentation Facility (CCIF) at the college.

Affordable inexpensice material

According to Dr. Xavier, activated carbon produced in this manner, utilising microwave technology, is relatively inexpensive and exhibits exceptional supercapacitor capability. The innovative microwave-assisted method has also opened new avenues for the production of activated carbon, which is under consideration for an Indian patent.

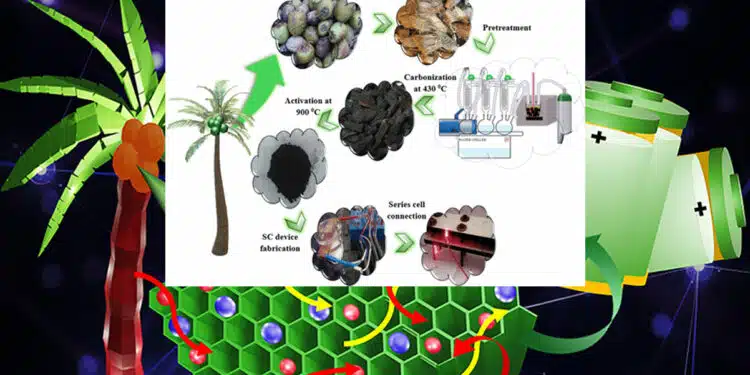

By utilising an advanced microwave pyrolysis reactor, the team was able to produce high-quality carbon within five minutes, eliminating impurities like ash and generating zero waste.

This innovative method not only saves time, but also yields activated carbon with an impressive surface area of 1,200 m2 g-1 and highly porous structures, making it an ideal material for various applications. The device’s high-power output is capable of powering two LEDs for 20 minutes, the researchers said.

CCIF, funded by the State government, is equipped with world-class state-of-the-art facilities, including advanced instruments like Nuclear Magnetic Resonance (NMR) spectrometer, Brunauer-Emmett-Teller (BET) analyser, fluorometer, electrochemical workstation, and PCR machines. The facility has already catered to the needs of researchers from over 50 colleges, six universities, and six national institutes.

Abstract

As a major agro waste of coconut, coconut husk is presented here as a cheap, abundant, novel, and sustainable green source of high-surface-area activated carbon for high-performance supercapacitor electrodes. The present communication satisfies one of the United Nations Sustainable Development Goals (UN goals) as an affordable, reliable, and sustainable solution for the existing energy technologies. The carbonization and the activation via a one-step integrated microwave pyrolysis system and vacuum furnace, respectively, are the production technologies used for the conversion of biomass into activated carbon. The chemical impregnation was performed in two different agents (KOH and H3PO4) and three higher activation temperatures (700, 800, and 900 °C), and their physical properties and the supercapacitive performances were analyzed and compared.

A high surface area of 1218 m2 g–1 was achieved for KOH impregnation (ACKOH 900) with a weight ratio of AC to KOH of 1:2 at an activation temperature of 900 °C, yielding an excellent specific capacitance of 342 F g–1, much higher than that of activated carbon with H3PO4 activation (243 F g–1). The energy storage performance was further carried out by fabricating a symmetric supercapacitor device in aqueous and polymer gel (PVA-H3PO4) electrolyte media, and excellent cyclic stability of nearly 100% was achieved with high power density for both KOH- and H3PO4-activated samples at high temperature, which can be interconnected with its enhanced surface area and high porosity that facilitates fast ion transport and improves energy storage performance. The fabricated supercapacitor cells, when used to power two red LEDs, showed a complete discharge at the end of 15 min while a maximum glow for 30 min was achieved for a single LED, which took 1 h for its complete discharge. Furthermore, via the present investigation, coconut-husk-derived activated carbon shows promise as a high capacitance, low cost, and renewable material, consequently suggesting a promising avenue toward high-power, affordable, renewable, and clean energy storage devices.

Conclusion

In summary, this work reveals the successful conversion of coconut husk biowaste into high-surface-area activated carbon via fast integrated pyrolysis followed by chemical activation with two activation agents at three different temperatures. FESEM micrographs with BET results revealed tubular honeycomb structures for activated carbon with mesopores on its walls, which plays a significant role in energy storage capacity. The choice of activation agent and temperature plays a crucial role in the surface area enhancement and thereby electrochemical properties, out of which ACKOH 900 was found to perform better than others with a specific capacitance of 342 F g–1.

Furthermore, a symmetric supercapacitor device was assembled in aqueous and polymer gel electrolytes, which could deliver an excellent capacitance performance with high power density. The polymer gel electrolyte allows a wide potential window of 2 V and delivers a specific capacitance of 224.4 F g–1 and a specific power of 746.63 W kg–1 with a capacitance retention rate of 100% after 20,000 charge–discharge cycles. The proposed coconut-husk-derived activated carbon has the potential to power the LED for 1 h in an aqueous electrolyte. The results recommended that the coconut husk biowaste-derived porous carbon is a promising one for sustainable and efficient green solutions for high-performance supercapacitor electrodes due to its availability, low cost, and eco-friendliness.

Read the complete article:

Effect of Activation Environment on Coconut-Husk-Derived Porous Activated Carbon for Renewable Energy Storage Applications; ACS Sustainable Resource Management Journal; https://doi.org/10.1021/acssusresmgt.4c00142