Rubycon’s HPB series based on PMLCAP technology is entering mass production in January 2026, bringing a compact, high‑power‑density alternative to traditional DC‑link film capacitors.

The series targets modern power electronics where higher switching frequencies, high ripple currents and elevated temperatures are becoming standard design constraints. For design engineers and purchasers, this marks the transition from early promotion to a fully specified, production‑ready platform with finalized datasheet values.

Key features and benefits

The Rubycon HPB series is a high‑voltage PMLCAP film capacitor family optimized as a DC‑link capacitor element in demanding power conversion stages. In many cases it enables replacement of bulky film capacitors with a significantly smaller footprint while maintaining or improving electrical performance.

Key characteristics include:

- PMLCAP construction that supports high power density versus conventional film DC‑link capacitors.

- Stable capacitance and electrical behavior up to 125°C, allowing placement closer to heat sources such as power semiconductors.

- Finalized ripple current ratings in the updated datasheet that reflect the behavior of actual mass‑production parts.

- Exclusive 10% capacitance tolerance across the series, simplifying stock management and worst‑case design calculations.

- Targeted AEC‑Q200 qualification, with the marking temporarily removed and planned for reintroduction after extended qualification is completed.

In practical terms, the HPB series helps reduce DC‑link volume and board area, increases thermal headroom and provides designers with clearer derating rules through the updated ripple current tables.

Typical applications

The Rubycon HPB PMLCAP series is positioned as a DC‑link workhorse for modern power conversion topologies, especially those using fast wide‑bandgap switches.

Typical use cases include:

- DC‑link filters in industrial and HVAC motor drives.

- On‑board chargers in electric and plug‑in hybrid vehicles, including high‑frequency PFC and DC/DC stages.

- Industrial drives and inverters where high ripple current and elevated ambient temperature are expected.

- High‑frequency converter stages based on SiC and GaN devices, where low ESL and stable capacitance at higher temperatures are critical.

In these circuits, the HPB capacitors act as the main energy buffer between the rectified input and the switching bridge, so their ability to handle ripple current and temperature directly affects converter efficiency, reliability and lifetime.

Technical highlights

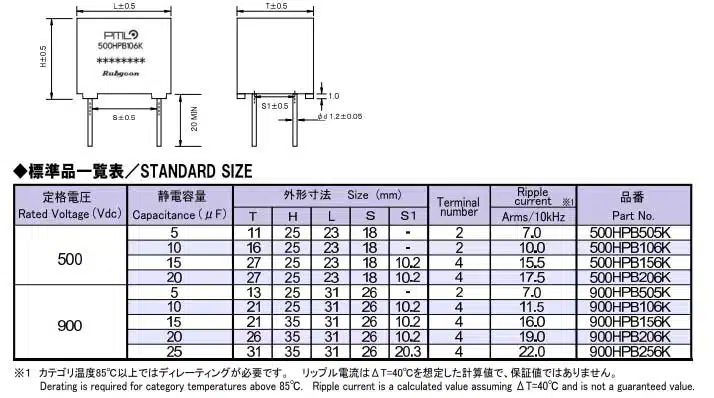

While detailed numerical values (capacitance, voltage ratings, ESR, ESL and ripple current) must be taken directly from the Rubycon HPB datasheet, the series is characterized by several important technical updates and positioning points according to the manufacturer documentation:

- Voltage and capacitance range suitable for DC‑link operation in typical mains‑connected and high‑power DC bus systems, according to the HPB datasheet.

- Ripple current ratings that have been adjusted to match final material and process configurations in series production, with updated tables in the latest datasheet.

- Operation up to 125°C, supporting high‑temperature environments such as compact on‑board chargers, motor drives in sealed housings and power modules with limited airflow.

- Focus on a single 10% capacitance tolerance option, which simplifies use in parallel/series banks and ensures tighter control of bus impedance.

- AEC‑Q200 marking temporarily removed in favor of completing extended qualification, with the intention to reintroduce the automotive status once tests are finalized.

For engineers, the key message is that the HPB series has moved from pre‑launch promotion to a mature, production‑ready platform with fully specified ripple and tolerance characteristics that can be used directly in derating and lifetime calculations.

Availability and part numbers

With start of production in January 2026, HPB parts move into mass‑production status rather than engineering samples only.

Source

This article is based on information from the official Codico news release announcing the series launch of the Rubycon HPB PMLCAP capacitor family in January 2026 and the associated manufacturer documentation, complemented with general design‑in considerations for DC‑link capacitors.