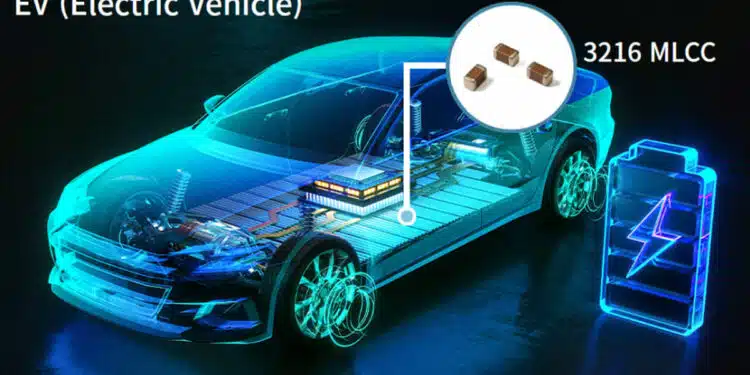

Samsung Electro-Mechanics launched 2,000V High-Voltage MLCC ceramic capacitors for suited for 800V electric vehicle battery management system (BMS).

The 800V EV system reduces charging time compared to the existing 400V BMS, increases mileage for electric vehicles due to lighter vehicle body. The new 2,000V MLCCs feature high reliability through independent development of raw materials and application of voltage distribution technology.

Samsung Electro-Mechanics strengthen the automotive business with the timely development of high-voltage MLCC- High-voltage MLCCs expected to grow at an average annual growth rate of 22%.

MLCC ceramic capacitors control the constant and stable flow of current in the circuits of electronic products, widely used in smartphones, PCs, IT devices, home appliances, automobiles, 5G, and IoT-related products. In particular, automobiles contain at least 4,000 to 20,000 MLCCs for power transmission, safety, autonomous driving, infotainment, powertrain, etc.

The battery management system of an electric vehicle controls the battery’s current, voltage, temperature, etc., and serves as the engine of an internal combustion engine vehicle. Electric vehicles are increasing in battery capacity because the driving distance is determined by the capacity of their batteries. The operating voltage will keep rising in order to quickly charge high-capacity batteries.

Currently, electric vehicles primarily use 400V battery management systems, but recently, 800V high-voltage battery systems are being applied mainly to Plug-in Hybrid Electric Vehicles (PHEV) and Battery Electric Vehicles (BEV). Compared to the existing 400V battery system, the 800V high-voltage battery system offers the advantages of a shorter charging time, a lighter vehicle body, and secured design space. Accordingly, it is anticipated that the proportion and demand for 2000V high-voltage and high-reliability MLCCs, which have a safety margin of more than 2 times that of stable operation in 800V high-voltage electric vehicles, would increase.

High-voltage MLCCs for electric vehicles are subjected to a voltage usage environment that is more than 300 times higher than the working voltage of 6.3V of existing MLCCs for IT, making it difficult to secure reliability due to problems such as cracks and electrical discharge inside the MLCC owing to high voltage. High-voltage MLCCs are high-skill, high-value products that guarantees durability and supplies current in challenging environments.

Samsung Electro-Mechanics applied a voltage distribution safety design that can stably distribute high voltages inside the MLCC to address this issue. Additionally, by using its own technique for developing raw dielectric materials, Samsung Electro-Mechanics has secured the reliability of MLCC products through dielectric atomization.

The products developed by Samsung Electro-Mechanics to operate stably in high voltages are two types: 1nF capacitance and 2.2nF in 3216 (3.2mm X 1.6mm) size which guarantee 2,000 V.

Samsung Electro-Mechanics independently developed raw materials and modified the structure of internal electrodes to develop MLCCs that operate stably even at high voltage environments, and obtained AEC-Q200 certification, a standard for automotive electronics reliability testing.

Choi Jeremy, Executive Vice President of Samsung Electro-Mechanics Component Unit, said, “The development of 2,000V high-voltage automotive MLCCs has proven Samsung Electro-Mechanics’ MLCC technology capabilities for electric vehicles,” adding, “Samsung Electro-Mechanics will continue to expand its MLCC market share for automotives through timely development of products in line with electric vehicle trends and market demands.”

The high-voltage MLCC market is expected to grow steadily due to the expansion of the electric vehicle market and the high voltage of battery systems to increase high-speed charging and driving distance. The high-voltage MLCC market is expected to grow at a CAGR of about 22% from $4 billion in 2024 to about $11 billion by 2029. (Source: Market research agency “Mordor Intelligence”)

The world’s second-largest MLCC manufacturer, Samsung Electro-Mechanics is strengthening its MLCC supply to global auto parts companies and automakers while also bolstering its lineup of high-value electronics products such as high temperature, high voltage, and high reliability, based on its IT MLCC technology developed since 1988.