Samsung Electro-Mechanics adds 1000V, 630V class automotive MLCC lineup with guaranteed voltage. Included in the on-board charger (OBC), the core of the electric vehicle charging system it ensures stable power supply and signal transmission from the battery system to support high-speed charging.

Samsung Electro-Mechanics develops high-voltage MLCCs that can be used in electric vehicles, targeting the automotive market by expanding its high-end automotive product lineup.

Samsung Electro-Mechanics announced that it has developed five types of automotive MLCCs that can provide stable power even in harsh usage environments of 630V (volts) or higher and plans to supply them to global automotive component customers.

MLCC(Multi-Layer Ceramic Capacitor) controls the constant and stable flow of current in the circuits of electronic products, widely used in smartphones, PCs, IT devices, home appliances, automobiles, 5G, and IoT-related products. In particular, automobiles contain at least 3,000 to 10,000 MLCCs for powertrain, safety, driving, infotainment, etc.

The automotive MLCCs developed this time by Samsung Electro-Mechanics are highly advanced and high-value-added products that guarantee a usage environment of 1000V and 630V, which is more than 100 times the working voltage of 6.3V of existing MLCCs for IT.

In other words, they have the durability to withstand high voltage and improve battery stability by eliminating high frequency noise in the battery system. Electric vehicle battery systems use voltages of up to 400V, and high voltage MLCCs of 630V and 1000V with more than double the safety margin are required to operate reliably in this environment.

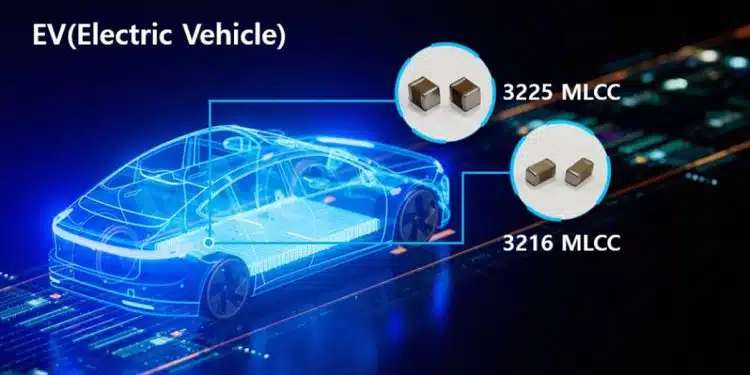

The products developed by Samsung Electro-Mechanics are five types in total: Three types including 15 nF (nanofarad-capacitance) and 22 nF in 3225 (3.2mmX2.5mm) size and 1nF capacitance in 3216 size, which guarantee 1000V, and two types with 33 nF capacitance in 3225 size and 10 nF capacitance in 3216 size, which guarantee 630V.

The on-board charger (OBC) of an electric vehicle is a device that receives power from an external electric charger to charge the vehicle’s battery and is one of the key components that determines the vehicle’s driving performance and the amount of electricity that can be charged at one time.

Previously, OBCs used film condensers to eliminate signal noise, but in recent years, the working voltage and frequency have been increasing to accelerate the charging speed. As a result, the demand for MLCCs, which have the characteristics of noise removal and high reliability in high-frequency environments, is increasing in electric vehicles.

Samsung Electro-Mechanics has developed MLCCs that operate stably even at high voltages by independently developing raw materials and changing the structure of internal electrodes.

In addition, it is very important to control the heat generated by the high voltage used in electric vehicles, and Samsung Electro-Mechanics has improved the heat generation characteristics by applying a new process method.

Choi Jeremy, Executive Vice President of Samsung Electro-Mechanics Component Unit, said, “The development of high-voltage automotive MLCCs has proven Samsung Electro-Mechanics’ automotive MLCC technology capabilities,” adding, “Samsung Electro-Mechanics will enhance its technological competitiveness by developing and manufacturing key raw materials for MLCCs in-house, and expand its market share in automotive MLCCs by internalizing facilities and strengthening production capacity.”

The high-voltage MLCC market is expected to grow steadily due to the expansion of the electric vehicle market and the high voltage/high performance of battery systems for high-speed charging and increased charging range.

The high-voltage MLCC market size is expected to grow from USD 4 billion in 2024 to approximately USD 11 billion by 2029, at a CAGR of approximately 22%.

Samsung Electro-Mechanics, the world’s second largest MLCC manufacturer, is strengthening its lineup of high-value-added automotive products for high temperature, high pressure, and high reliability based on its technological prowess in the ultra-small and ultra-high capacity MLCC segment and is expanding its MLCC supply to global automotive component companies and automakers.