Samsung Electro-Mechanics announced on September 10 that it will mass-produce coupled power inductors, which feature two power inductors on a single chip, and will target the market by expanding its high-end product lineup.

Power inductors, referred to as the “second MLCC,” are core electronic components that are applied to power circuits to convert electricity (power) from batteries into power required by semiconductors and stably supply current.

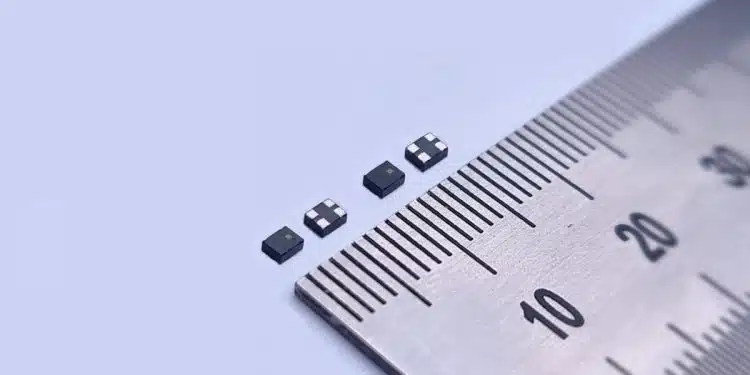

Samsung Electro-Mechanics has developed two types of coupled power inductors with low losses and DCR resistance value (a characteristic that hinders the flow of current): the 2016 size (2.0 mm wide and 1.6 mm long) and the 2218 size (2.2 mm wide and 1.8 mm long).

These products are mounted near the CPU (central processing unit), which serves as the brain of a PC, to provide stable current to the CPU. In particular, the higher the performance of the CPU, the more current it uses, so a power inductor with low power loss is required.

Power inductors consume power based on the resistance value of the coils wound inside. The greater the resistance, the greater the power consumed.

Previously, two power inductors were connected in parallel to reduce the resistance value, but this has the disadvantage of increasing the number of components and limiting the freedom of circuit design.

Samsung Electro-Mechanics has applied a coupled structure with two coils stacked on top of each other to realize a single chip. Coupled power inductors are one of the most difficult technologies to implement among power inductor products due to issues such as insulation between coils and magnetic field interference.

Samsung Electro-Mechanics’ coupled power inductor is a thin-film type product formed by electroplating thin coil shapes on a package substrate and is characterized by superior electrical properties such as insulation (less electromagnetic interference) and resistance value than competing products that are made by directly winding coils on magnetic materials (objects with magnetic properties).

Samsung Electro-Mechanics independently developed a magnetic material with excellent properties and low loss based on the material technology accumulated through MLCC and applied the photosensitization method (a manufacturing method that uses light to engrave circuits) used in semiconductor package substrate manufacturing to precisely create the spacing between the two coils to minimize changes in product properties due to the environment.

The power inductor market size is expected to reach approximately USD 3.65 billion (KRW 4.85 trillion) by 2028, at a CAGR of approximately 9%. The power inductor market is expected to grow steadily centered on high-performance products due to the increasing demand for high-performance and multifunctionalization of electronic devices and the expansion of the automotive industry such as autonomous driving and electric vehicles.

“Power inductors are becoming a key component in differentiating the performance of semiconductors as the demand for higher specifications and higher performance of semiconductors continues,” said Chang Duckhyun, CEO of Samsung Electro-Mechanics. “Samsung Electro-Mechanics will develop differentiated products based on the world’s best materials and process technologies to become a top-tier tech company leading the power inductor market.”

In December of last year, Samsung Electro-Mechanics implemented an organizational change that elevated the ‘Electronic Component Team’ in charge of power inductors, which is being developed as the second MLCC, to the ‘Electronic Component Business Team,’ and is embarking on a full-scale business expansion.