KEMET Technical Blog Post released and application note on usage of polymer capacitors in Solid State Drives (SSDs).

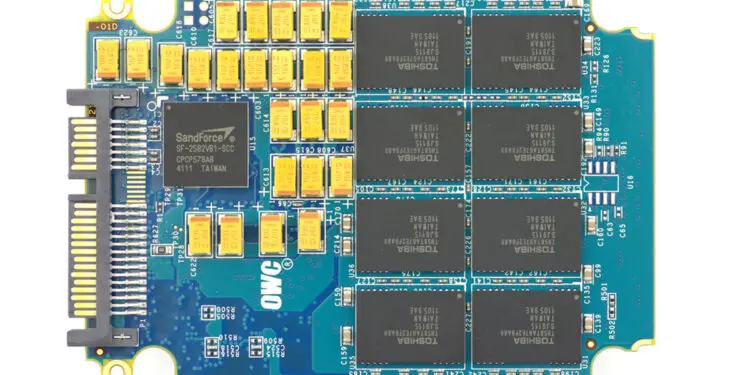

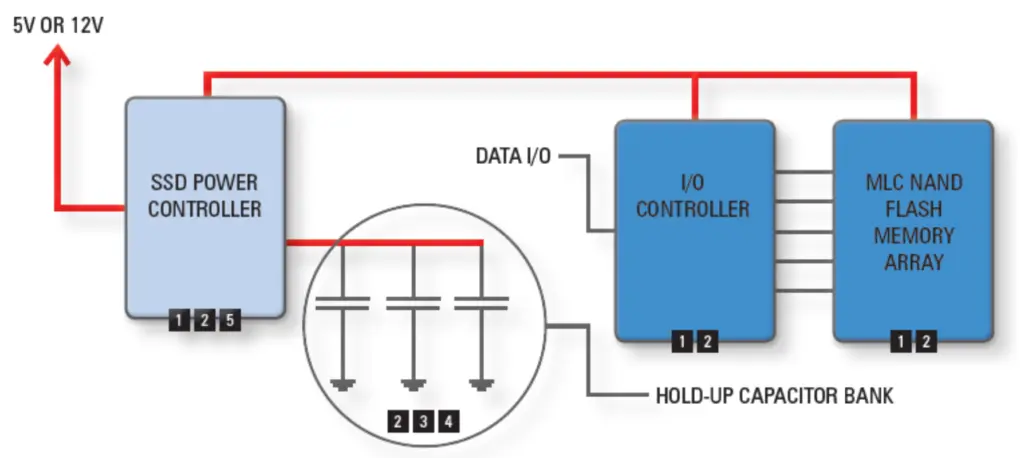

SSD Solution features a bank of capacitors to hold up the power rail when system power is lost. This energy gives the drive time to flush its caches and write its information tables. KEMET SSD Solution includes several capacitors options, in this document the tantalum polymer technology and portfolio offering is presented.

Introducing Hold-Up

Protecting data isn’t just about cyber security, it is about making sure your data gets to where it is meant to go. A lot could happen from the time you click save or upload to the time your data is sitting in its destination. One potential cause for concern is what happens if that server farm you’re sending your data to loses power. That’s where SSD holdup capacitors come in. Our polymer electrolytic capacitors make excellent devices to use in hold-up circuits. The circuit in figure 1 shows a typical decoupling implementation.

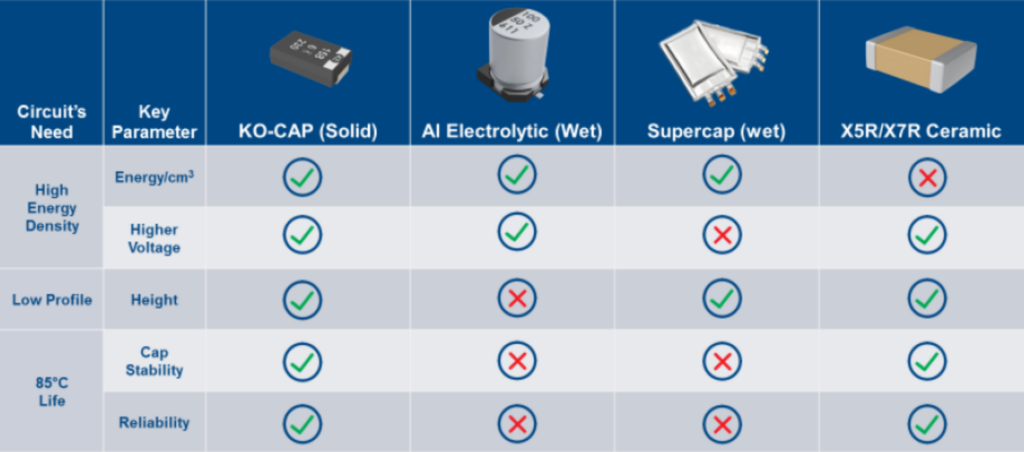

The Options for Hold-Up

Creating an effective hold-up circuit is not as easy as adding one-hundred 10 uF ceramic capacitors in parallel and calling it a day. There are many factors that go into consideration when creating an effective hold-up circuit. Things like stability, reliability, form factor, operating voltage, and energy density must all be considered. At an enterprise level, size is critical because SSDs are inherently thin and small so that many can be fit in a single system. Reliability and operational life is critical because enterprise systems usually have very extended “up” times and undergo many cycles of read/write operations. Perhaps most important is energy density. In a general sense, the greater the energy density of the storage device, the less of them are needed. Each of the four basic families of capacitors have their pros and cons due to their operating physics and properties.

Energy Density

Supercapacitors and aluminum electrolytic have perhaps the best energy density of the group, but their limitations in voltage and size don’t make them suitable options for hold-up. Ceramic capacitors can be very small but conversely, very limited in energy density, especially on a per-part level. Once again, polymer electrolytic capacitors have very

acceptable energy density for a hold-up application.

Size

While their amount of capacitance is sufficient, supercapacitors and aluminum electrolytic capacitors are usually prohibitively large. Some ceramic capacitors can be quite small but those small ones don’t have enough capacitance. Polymer electrolytic capacitors have excellent volumetric efficiency, it is possible to have the necessary capacitance in a sufficiently small capacitor.

Reliability

Reliability is something in which there is no compromise. Enterprise level SSDs require the utmost best as far as reliability goes. Such strict requirements limit the options to ceramic and polymer electrolytic as both supercapacitors and aluminum electrolytic have various wear-out mechanisms. As we have seen before ceramic capacitors are not as suitable for hold-up circuits as polymer electrolytic, so polymer wins this category.

Voltage

SSD power controllers usually contain a combined boost-buck converter to use capacitor banks in the range of 3.3 to 35 volts. That is well within the voltage rating for polymer electrolytic, ceramic, and aluminum electrolytic. Perhaps one of the biggest drawbacks to supercapacitors is their limited operating voltage. It is generally insufficient for enterprise holdup.

Polymer electrolytic capacitors, such as our T54x (https://content.kemet.com/datasheets/KEM_T2079_SSD.pdf) , have the right mixture of size, voltage, energy density, and reliability.

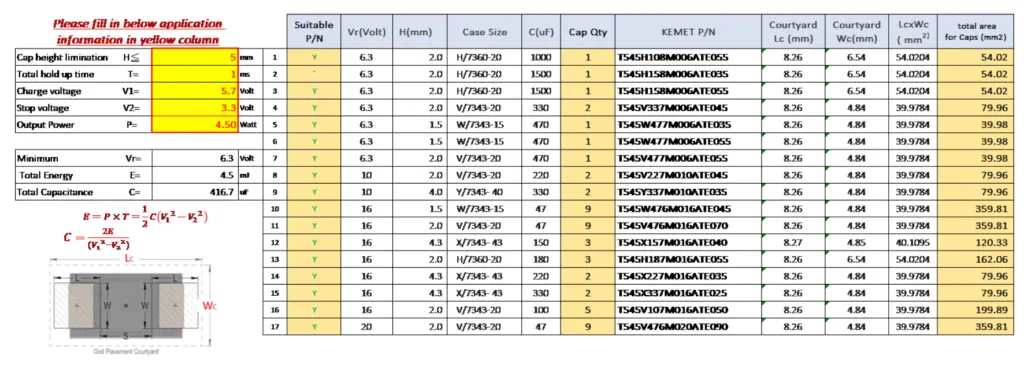

Calculating Hold-Up

KEMET provides designers an on-line calculator (https://www.kemet.com/en/us/ssd-configuration-calculator.html), figure 2. This tool allows the designers to fill the height restriction, total hold up timing, the charge and drop voltage, and the total output power.

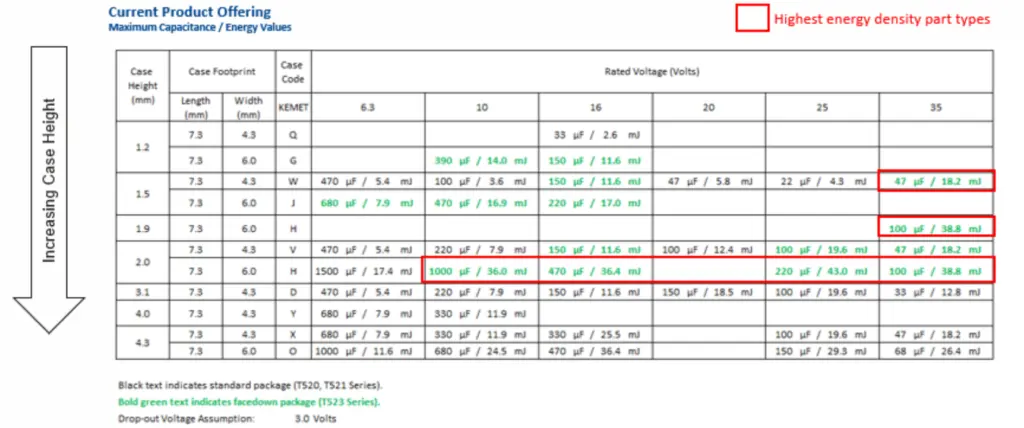

The tantalum polymer with smaller footprint (<7343) provide more flexibility with orientation in the board, but the larget footprint (7343 and 7360) are the most commom used and reduce the board space. The highest energy density part numbers include the 7343-15 47uF35V (ultra limited max H 1,5mm) and the 7360-20 220uF25V and 100uF35V (limited max H 2,0mm)

The part numbers and energies are shown in figure 3.

Conclusions

The maximum energy offered by the KEMET Polymer SSD portfolio are solutions to the SSD designers where space board saving, high volumetric efficiency/miniturization and reliability are required.

KEMET FAE, James Lewis explains the hold-up in this video with EEJournal