Source: Electronic Design article

by Lou Frenzel. The seemingly ubiquitous bypass capacitor is an important component in design, especially when dealing with high frequencies. But what’s the driving force behind its usage?

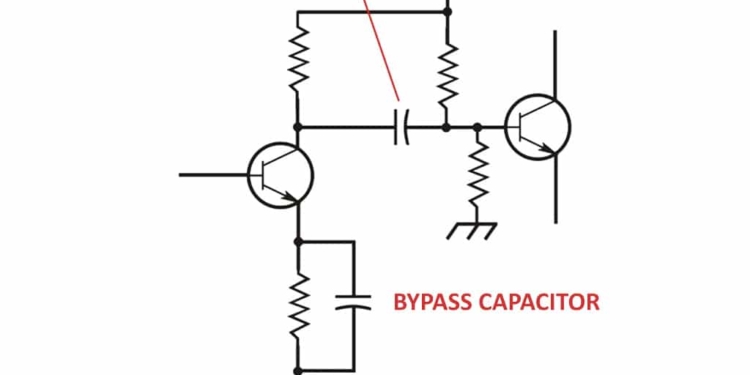

Just recently, I was eavesdropping on several engineer acquaintances of mine discussing bypass capacitors. Also known as decoupling capacitors, these capacitors are everywhere. Some products contain hundreds of capacitors, many of which are bypass capacitors. That got me to thinking: “How much do most engineers actually know about bypassing?” It’s probably not something you learned in school.

As engineers, many of us probably learned bypassing/decoupling by observing what others have done; that is, just put a 0.1-µF ceramic capacitor on each IC power connection and be done with it. That seems to work in many designs. But as it turns out, there’s a bit more to it than that. With MCUs and other digital circuitry running many megahertz or even gigahertz, the noise they generate is a problem. And the use of switch-mode power supplies (SMPS) contributes to the noise. Therefore, we bypass.

The problem arises mainly from the need for one dc supply to furnish voltage to multiple ICs on a printed circuit board (PCB) or across multiple PCBs. The power supply, and each attached circuit, generate some noise, high current transients, or whatever. These get passed around via the common dc power connection and other conducted means. This isn’t good. The traditional approach is to add a low-pass filter at each IC power connection. Isn’t that what bypassing is?

The basic solution in serious cases is to add multiple bypass capacitors to deal with the various types of noise. Since capacitors store a charge, they can minimize dc power-supply transients. Capacitors are supposed to smooth the dc supply output so that it looks like a clean horizontal line on the scope screen. Well, almost. Capacitors also provide a low impedance path to ground for unwanted high-frequency noise signals.

High-Frequency Equipment Designs

The need for effective bypassing really shows up when designing equipment operating at very high frequencies, like 50 MHz and above. At these frequencies, any stray or distributed inductance or the parasitic inductance of a capacitor become major impedances. Long connecting wires, long PCB traces, and the parasitic inductance in the capacitors help distribute all the noise around to the various ICs connected to the power supply.

Consequently, the first part of the solution is to minimize this inductance by reducing cable lengths and making PCB traces short. Luckily, many designs are being implemented on very small boards, so the trace inductance isn’t too much of a problem. Then, as you undoubtedly learned from experience, put a bypass capacitor on the power pin of each IC. And that means soldering the capacitor right on the pin itself to reduce any inductance between the supply and the IC.

For best results, you should experiment with the value of that capacitor. While the traditional 0.1-µF capacitor usually works, you should test different values while observing the noise on the power pin on your scope. In some cases, you may only need 0.01 µF or 0.001 µF—even mid to high pF will do the job. In some products, one bypass capacitor per chip isn’t needed. It may be a case of overkill. Nevertheless, if you can afford the minor extra expense, don’t take any chances. Bypass everything in sight. Experiment. Every design is different.

Don’t Skimp on Quality

The quality of the capacitor is another issue. Its equivalent series resistance (ESR) is a major factor in high-frequency bypassing. In many low-frequency designs, we ignore the ESR, and in bypassing, it’s an often-overlooked factor. Another typically ignored characteristic is equivalent series inductance (ESL). It too is a capacitor parasitic. While the ESL is very low (pH), it can affect the bypassing. The issue is that at some frequency, the capacitor becomes self-resonant. When triggered by noise or pulses, the capacitor oscillates or rings.

A common solution is to put two or more different-sized bypass capacitors in parallel, thereby making the lowest possible overall impedance. The use of multiple parallel bypass capacitors will minimize the effect of the parasitics in the capacitors. Remember to design the PCB layout to accommodate multiple bypass capacitors, in parallel.

As for what type of capacitor to use, your best bet is ceramic. It has a very low ESR and ESL and comes in a wide range of values. Mica capacitors have even lower ESR/ESL, but these are very expensive. The ceramic capacitors are available in most of the standard SMD sizes. And they’re cheap.

Of course, the standard practice of decoupling the PCB from the dc supply is still a good idea. Use an electrolytic on the board where the dc power enters the board. 10 µF is common, but a lower value may work. A good alternative is large ceramic capacitor too.

So, what you probably already knew is correct—a big capacitor to decouple the board from the dc source and small capacitors on each chip. Use multiple parallel capacitors at the higher frequencies. Don’t just dismiss bypassing. Fine-tune it to your design by really understanding what’s going on.