inter-connect knowledge blog

Contact Normal Force Parameters

After this discussion about the effects of contact normal force, attention now turns to the design and material parameters that...

Read moreDetailsContact Force and Mating Mechanics

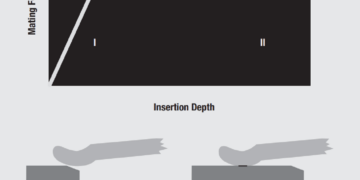

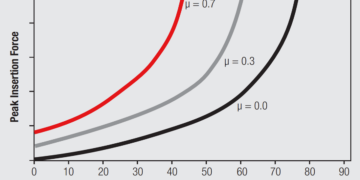

Consider now the effects of contact force on the mating mechanics of a connector. Figure 2.20 schematically illustrates the mating,...

Read moreDetailsContact Force and Mating Wear/Durability

The variation of mating wear/durability as a function of contact force is a good example of normal force optimization. The...

Read moreDetailsSeparable Connections and Contact Force Optimization

Before the question of optimizing contact force is addressed it is necessary to ask a more fundamental question: “What does...

Read moreDetailsContact Spring Requirements

As discussed in Chapter I/1.2.2 Contact Springs, the three basic requirements for the contact spring are: • Electrical conductivity• Creating...

Read moreDetailsSeparable Interface Requirements

Separability requires that a connector has the capacity to be mated and unmated multiple times without any unacceptable effect on...

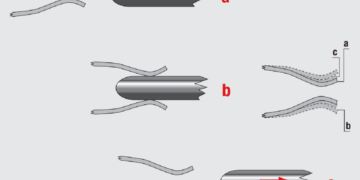

Read moreDetailsContact Springs

Recall the functional definition of a connector from Chapter I/1.1 Connector Function. A connector is an electromechanical system which provides...

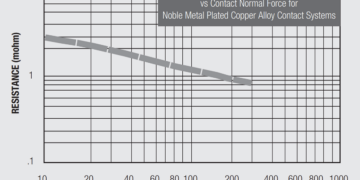

Read moreDetailsNoble Contact Finishes

The classic noble metal contact finish system is gold over nickel as discussed in Chapter II/2.1.2 Contact Finish Degradation Mechanisms....

Read moreDetailsNon-noble Finishes

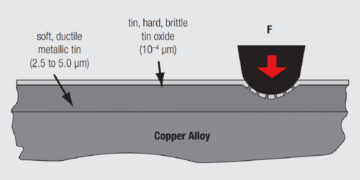

Tin and silver are the two most common used non-noble finishes. Tin finishes are used in a wide range of...

Read moreDetailsContact Finish Selection

Selection of an appropriate finish system for a given connector application requires consideration of a number of connector and application...

Read moreDetails