inter-connect knowledge blog

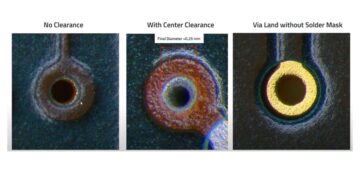

PCB Via Design Selection; Plugging-Filling-Tenting

This Würth Elektronik webinar explains some basic PCB design via selection and considerations including via clearance in the solder mask,...

Read moreDetailsBASIC PCB Design Rules – Layout

In this Würth Elektronik webinar you will learn more about PCB design rules and layout. Würth Elektronik BASIC Design Rules...

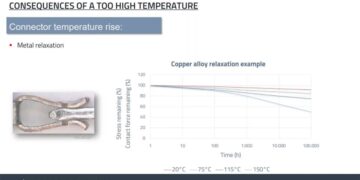

Read moreDetailsConnector Temperature Rise and Derating

In this presentation from Würth Elektronik on Connector Temperature Rise and Derating shows how a connector is designed regarding current...

Read moreDetailsConnector Temperature and Current Ratings Challenges

Thermal management and temperature derating have always been something that designers have had to plan for to keep their products...

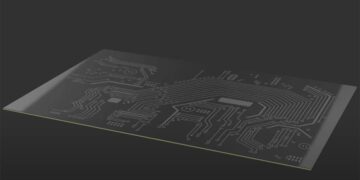

Read moreDetailsPCBs Explained for Beginners

This Würth Elektronik video describes the production of a simple printed circuit boards in a way that is suitable for...

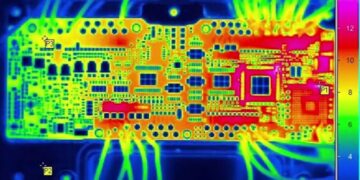

Read moreDetailsThermal Management of High Performance PCB System

This Würth Elektronik video tutorial focuses on the possibilities of intelligent PCB-based thermal management and which PCB design goals can...

Read moreDetailsConnector Materials and Processes

This article will provide a basic discussion of connector materials and manufacturing processes. Chapter I/1.4.1 Contact Finish Electroplating on contact...

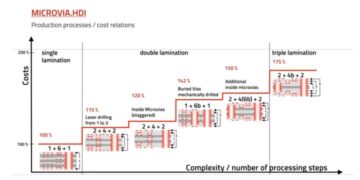

Read moreDetailsHigh Density Interconnect PCBs

This webinar from Würth Elektronik continue series "PCB Production" with High Density Interconnect (HDI) PCBs. In this video you will...

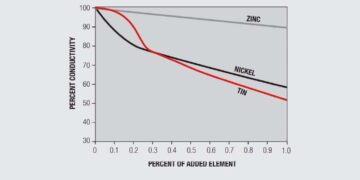

Read moreDetailsCopper Alloy Metallurgy and Processing

The majority of connector contacts are manufactured from copper alloys due to the combination of high electrical conductivity and good...

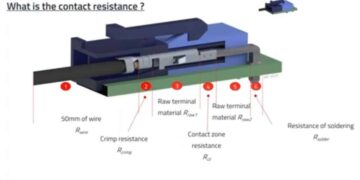

Read moreDetailsHow to Make a Good Electrical Contact for Inter-Connection

This Würth Elektronik webinar explains influence of different parameters and how to make a good electrical contact for reliable inter-connection....

Read moreDetails