Source: GAM news

Waltham, MA and Runcorn Cheshire United Kingdom – March 26, 2018 – Global Advanced Metals Pty Ltd (GAM), a leading producer of tantalum and niobium products, along with LPW Technology (LPW), a global manufacturer of high-quality metal powders exclusively for additive manufacturing (AM), announce a cooperative agreement to further demonstrate the suitability of spheroidized tantalum for 3D metal printing.

Across this emerging industry there are few examples of additively manufactured refractory metals, and a need exists for a more thorough proof of concept and development of print criteria. GAM is filling this void and expanding its product portfolio.

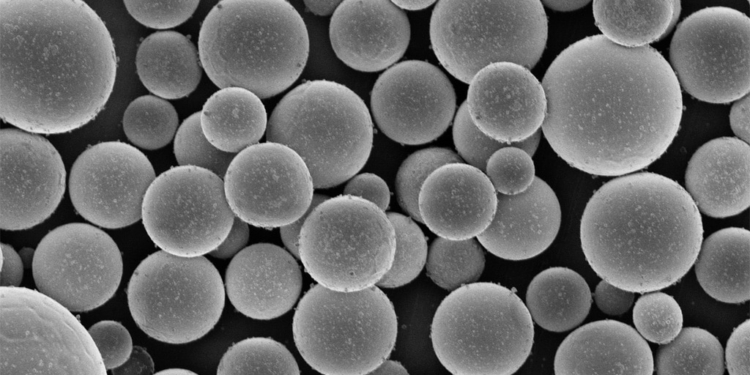

GAM is the world leader in tantalum powder technology and offers powders in nodular, angular, fractal and spherical morphologies for a wide range of critical applications. Successful demonstration of laser 3D printing of tantalum offers GAM customers another powder option with which to serve medical, dental, military, aerospace and other markets via tantalum-based additive manufacturing. Tantalum offers superior osteointegration, higher biocompatibility and reduced stress shielding with respect to current metals and alloys used for medical implants.

“Leveraging LPW’s laser powder bed fusion expertise, developed by viewing AM from the perspective of the powder, represents one step of our strategy to extend our offering in tantalum and other refractory metals to the additive manufacturing marketplace. We can now measure and share physicochemical data for both our spherical tantalum and the resulting 3D printed part and bring this solution to our partners, including practitioners, designers and manufacturers of tantalum based surgical implants and other high reliability and critical devices,” said Andrew O’Donovan, CEO, GAM.

LPW Technology is the market leader in the manufacture, development and processing of high-quality metal powders for additive manufacturing, and provides a comprehensive range of solutions and services for the AM industry. These include the development and testing of new alloys, expert application support, and innovative end-to-end hardware and software.

“This initiative demonstrates the benefits of two experts in their fields partnering to expand the materials knowledge-base for AM and accelerate its adoption for production,” said Ben Ferrar, LPW’s COO. “The performance of metal powder feedstock is key to building consistent AM parts and delivering the required mechanical properties.

“This work will further develop understanding of the factors affecting tantalum powder spheroidization and how it performs in the AM process, adding assurance to metal AM producers of the material compatibility for AM production.”

featured image: high flow,high purity tantalum powder, Image credit: Business Wire