Advances in capacitor grade tantalum powder to higher charge capability (CV), higher purity, and higher voltage capability have enabled tantalum capacitors to reach higher energy density levels as described in Global Advanced Metals (GAM) article.

A tantalum capacitor is a passive electronic component commonly used in wide range of electronic applications. A capacitor is comprised of an anode and a cathode separated by a dielectric. In the case of a tantalum capacitor, the anode is tantalum powder, the cathode is made by silver and graphite coating deposited on a semi-conductive electrolyte (MnO2 or conductive polymer), and the dielectric is tantalum pentoxide (Ta2O5) formed on the surface of the tantalum powder. Today’s tantalum capacitors have the highest volumetric efficiency (charge per size) and the highest reliability when compared to other capacitor technologies.

Advances in tantalum powder have enabled tantalum capacitors to be the best fit for many demanding electronic applications with combined requirements for high reliability and highest energy density in low profile, compact size.

Characteristics required for tantalum powder

(a) High Capacitance and Voltage (CV)

A capacitor’s ability to store electrical charge (Q) is defined by its capacitance (C) and the voltage (V) applied across the anode and cathode:

Q= C x V

Capacitors with higher charge carrying capacity are designed to handle higher voltages (V) and/or higher capacitance (C). Increasing voltage depends on many factors, including dielectric properties, purity levels of many sub-materials in the capacitor, and dimensional considerations. Increasing capacitance depends on the dimensions and physical properties of the dielectric layer.

In tantalum capacitors, capacitance (C) is directly proportional to the specific surface area (SSA) of the Ta2O5 dielectric layer of the tantalum pellet. SSA of the tantalum pellet depends on the density and sintering temperature when the pellet is made, but largely depends on the particle size of the tantalum powder used to construct the pellet. In order to improve a capacitor charge carrying capacity (CV), a powder having fine particles giving high surface area is required. The fine particles can be obtained by adjusting the manufacturing conditions when tantalum is reduced with sodium (Na) or magnesium (Mg), and using other additives.

SEM images of a range of tantalum powders are shown in Figure 1. As can be seen from the figure, the high CV tantalum capacitor grade powder has smaller particle size, thus higher charge carrying capacity.

(b) High reliability

High purity tantalum powder enables tantalum capacitors to be one of the most reliable capacitor technologies. On the rare occasion that a tantalum capacitor fails, the most common failure mode is leakage current caused by the crystallization of the amorphous anodized film that comprises the dielectric layer. If a micro defect occurs in the Ta2O5 anodic oxide film, an electric current concentrates on the point of the defect, causing local resistive heat generation. This heat causes the amorphous film to crystallize, increasing the leakage current of the capacitor and reducing reliability. Therefore, a tantalum capacitor grade powder with few impurities is required to minimize micro defects in the anodic oxide film.

Other important tantalum capacitor grade powder characteristics include flowability and formability, which supports the press molding of the tantalum capacitor pellet. The flowability and formability depend on the bulk density of the powder, the particle size distribution, the cohesion strength of agglomerated powder, etc., and are greatly affected by the conditions of the tantalum capacitor grade powder manufacturing process. Tantalum capacitor grade powder of high purity, flowability, reliability, and formability as produced by Global Advanced Metals (GAM) are used in a broad range of applications like wearable electronics, laptops, and even in space applications such as the Mars rover.

(c) Polymer and MnO2 electrolyte type friendly

Conventional tantalum capacitors are using MnO2 material as electrolyte that provide excellent robustness and reliability in wide range of operating conditions. Conductive polymer electrolyte tantalum capacitors (sometimes just called polymer capacitors) are using conductive organic material with higher conductivity that enable reduction of ESR (Equivalent Series Resistance) and higher power ratings of the capacitors. Advantage of polymer capacitors is also in lower processing / curing temperatures compare to MnO2 that impose lower damage to the dielectric and in consequence even lower voltage with higher capacitance values can be achieved using the high CV tantalum powders.

History of high CV powder

A major benefit of tantalum capacitors is their small size and high capacitance. The history of increasing the capacitance of tantalum capacitors can be viewed from both the powder and capacitor manufacturer’s point of view:

- From the view of tantalum capacitor grade powder manufacturers, the history of higher capacitance is the history of primary particle miniaturization. Figure 2 shows CV values of the most advanced tantalum powder in each era where the CV of tantalum capacitor grade powder has increased about 80 times in 30 years from 3kCV/g in 1965 to 250kCV/g in 2009. 300kCV/g (and higher CV) powder is in itself unique. This powder is produced using GAM’s “Flame Synthesis” technology, where fine primary particles are obtained by reducing tantalum pentachloride in a Na flame. Figure 2 also shows a decrease in the formation voltage that has accompanied the increase in CV/g.

- From the view of capacitor manufacturers, the history of higher capacitance is the history of lowering the pellet sintering temperature and formation voltage. Figure 3 shows the relationship between the pellet sintering temperature and the capacitance value. Figure 3 also shows that the pellet sintering temperature decreases as the powder CV increases and that the pellets using the latest 250kCV/g powder and 300kCV/g powder are sintered below 1200 ° C.

High CV powder at middle voltage

High voltage type tantalum capacitor grade powder (HV powder) is a powder developed to have a higher capacitance in a higher formation voltage (Vf) region than a conventional powder. For example, GAM has advanced the S-15HV powder to be used at 40Vf, up from 20Vf for the standard S-15 powder (Note: S-15 is a typical GAM product name for 150KCV powder and GAM follows similar naming designation for other tantalum capacitor grade powders). The HV powder technology was originally established to extend the capabilities of the popular line of 70 kCV/g powders. These tantalum capacitor grade powders produced by GAM find use in demanding applications like data storage solid-state devices (SSD), telecommunications infrastructure, and automotive.

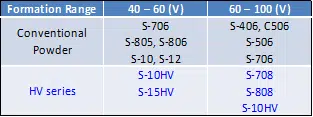

Table 1 shows a comparison between the existing powder and the HV powder according to the formation voltage.

Generally, when a tantalum powder is anodized with higher formation voltages, the CV value decreases (loss of charge carrying capacity). The reduction in CV is due to the breaking of the electrical bond between the primary particles within the anode, thus reducing the effective dielectric area of the capacitor. In order to prevent this in HV powder, the manufacturing process is adjusted so that the primary particle size and the bonding neck connecting them become thicker.

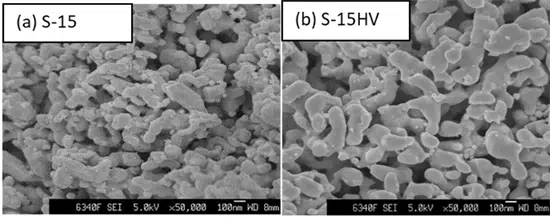

Figure 4 shows SEM photographs of S-15, a standard product, compared to S-15HV, an HV type powder. It is apparent the S-15HV powder results in an anode with larger particle to particle connectivity; larger necks between particles. Since the HV type powder maintains the bond between the primary particles due to the thick neck, it will exhibit a higher capacitance than the standard type during high-voltage formation.

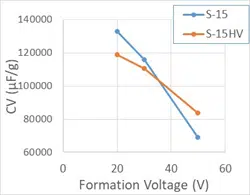

Figure 5 demonstrates the CV value with respect to the formation voltage. At low formation voltage (ex. 20Vf), S-15HV has a lower CV than S-15, but it has ~15% higher CV than S-15 at 50Vf.

Higher CV/g powder enables miniaturization

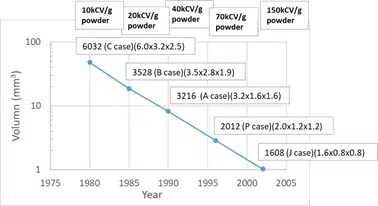

Figure 6 shows an example of how a tantalum capacitor (10 μF product) has been miniaturized through the increase in powder CV. The volume of the tantalum capacitor is reduced to 1/47th of the original by increasing the powder CV by 15 times. The decrease in tantalum capacitor volume is larger than the increase in powder CV because it includes the influence of volumetric efficiency improvement activities by capacitor manufacturers.

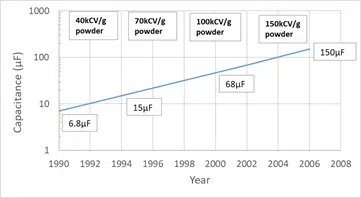

Figure 7 shows an example of how the capacity of tantalum capacitors (A-case, 6.3Vr product) has increased due to the increase in tantalum capacitor grade powder CV. The capacity of the tantalum capacitor has increased to about 22 times by increasing the tantalum capacitor grade powder CV by about 4 times.

Figures 6 and 7 show the transition until around 2005, where the industry changed focus due to the competitive pressure of miniaturization with MLCCs. The tantalum capacitor industry turned to differentiating by lowering profile and expansion of medium/high voltage products. GAM high CV tantalum capacitor grade powders are playing a major role in these activities.

Conclusion

Emerging electronics technologies like 5G, AR/VR, AI, and ADAS combined with the exponential growth of data will push capacitor technologies to further miniaturize, improve charge capability, improve reliability, and improve voltage capability.

In the case of tantalum capacitors, keeping pace with these advancing technologies will require continuous development by the tantalum capacitor manufacturers and tantalum capacitor grade powder manufacturers.

The Global Advanced Metals team is ideally poised and structured to meet and exceed these demands for new generation of high energy tantalum and tantalum polymer capacitors.

The proposed test is especially relevant for assessing the acceptability of the anode of high-temperature capacitors1, whereof the cost of the TC, due to the complexity of its production, significantly exceeds the contribution the cost of tantalum powder used in its anode.

1. Dennis M. Zogbi “High-Temperature Capacitors: New Applications and Market Opportunities” https://www.tti.com/content/ttiinc/en/resources/marketeye/categories/passives/me-zogbi-20211118.html