This white paper written by Robert Lu, KYOCERA AVX, discusses the advantages of C0G high voltage MLCC ceramic capacitors when compared to film capacitors in DC/DC and On Board Chargers (OBC).

Capacitance stability is paramount when selecting the appropriate resonant capacitor for resonant circuits. Desirable characteristics include minimal variations with temperature, voltage, and frequency fluctuations.

While film capacitors offer a suitable option for certain applications, advancements in Micro-Laminated Ceramic Capacitor (MLCC) technology have enhanced the performance of other capacitor dielectrics.

In DC-DC/OBC applications, C0G High Voltage MLCCs emerge as a more suitable choice compared to film capacitors. They exhibit minimal capacitance variation with temperature and possess a low DF dissipation factor at high frequencies.

Understanding DC-DC And OBC LLC Circuit

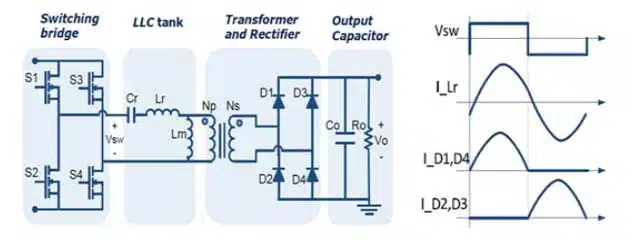

In a DC-DC converter, the LLC resonant circuit efficiently converts the DC voltage to the desired output voltage. When the switching MOSFET is on, it applies the supply voltage to the resonant inductor, storing energy. Conversely, when the MOSFET is off, the inductor releases this energy, which is then transferred to the load through the resonant capacitor. By controlling the MOSFET’s on-off time, the output voltage can be adjusted.

further reference: LLC Resonant Converter Design and Calculation

In on-board chargers (OBCs), the LLC resonant circuit plays a crucial role in converting the input alternating current into direct current to charge the battery of an electric vehicle (EV). Similar to DC-DC converters, the LLC resonant circuit regulates the output voltage by controlling the MOSFET’s on-off time.

One of the key advantages of the LLC resonant circuit is the zero voltage on (ZVS) of the two main MOS switches on the primary side and the zero current off (ZCS) of the secondary rectifier diode. This soft switching technology significantly reduces the power supply’s switching losses, enhancing the converter’s efficiency and power density. Additionally, the LLC resonant circuit ensures constant output voltage, improving the stability and reliability of the power supply.

As illustrated in Figure 1, Lr and Lm represent the leakage inductance and excitation magnetic inductance of the transformer. These inductances, along with the capacitor Cr, form a resonant circuit. The LLC converter comprises two inductors (Lr, Lm) and a capacitor (C), where the resonant capacitor is connected in series with the transformer. This configuration is also known as a series resonance circuit.

In contrast to the common DC-DC converter, which employs pulse amplitude modulation (PAM) mode to achieve the desired output voltage, the LLC converter utilizes pulse frequency modulation (PFM) mode. In PFM mode, the pulse amplitude remains constant while controlling the switching frequency. Therefore, the resonant capacitors must possess specific characteristics to operate effectively in this mode.

C0G High Voltage MLCCs Replace Film Capacitors In DC-DC/OBC LLC Circuit

The usual working voltage in DC-DC/OBC applications ranges from 0-400V, with peak voltage at 450V, and working frequency higher than 100khz. The capacitance stability is a crucial element when considering the right resonant capacitor for resonant circuits; minimum variations with shifts in temperature, voltage, and frequency fluctuation are required.

When subjected to the larger rectangular waveform of voltage, the resonant capacitor must endure a consistent high AC voltage, enabling the LLC converter to transfer power. The high ripple current flowing through the resonant capacitor requires appropriate equivalent series resistance (ESR).

Film capacitors (film caps) have represented the common choice, fitting the requirements when considering voltage, capacitance, ESR value, and temperature, with a rated voltage of 600-1000 V and capacitance of 1-10µf. The common dielectrics for film caps include Polyester, PET (polyethyleneterephthalate) and PP (polypropylene).

When choosing film caps, the dv/dt value should be taken into account (Equation 1). Standard values in the industry include AC 50hz/380v with a maximum dv/dt value at 0.027 V/µs. A 0.47µF capacitor under 500v/µs dv/dt pulse generates 235 A current. Stacked film cap with 5mm lead spacing can handle around 800v/µs dv/dt. The failure mechanism of film caps is not suited for fast dv/dt even with the ESR value at less than 10 mΩ (Equation 2). In some applications with a rapid increase in high current generate extremely high heat, which softens and melts the film cap’s dielectrics. This contributes to a decrease in infrared radiation and thermal failure.

Other weaknesses of film caps include:

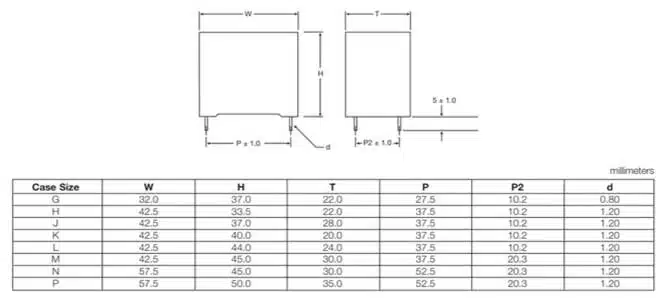

- Size: The film cap’s box-like shape takes up considerable room on the PCB (typical dimensions shown in Figure 2)

- Wave soldering: The film cap’s leads requires wave soldering during PCBA, potentially interfering with the customer’s manufacturing process

Despite its limitations, finding a suitable replacement for film capacitors proved to be a significant challenge in the past. Initially, the C0G (NP0) dielectric material was not an ideal choice due to its low permittivity, which limited the production of high capacitance capacitors with high voltage. However, advancements in MLCC technology have since improved the capabilities of NP0 high voltage MLCCs, enabling them to accommodate higher capacitance and voltage within a compact size. This has made them an effective replacement for film capacitors.

As the demand for smaller and more powerful DC-DC/OBCs continues to grow, customers are increasingly seeking a higher power-to-density ratio. Engineers recognize the advantages of high voltage C0G MLCCs packaged in miniature sizes compared to film capacitors.

C0G MLCCs remain a viable option as electric vehicles and other applications increasingly adopt wide-bandgap (WBG) semiconductor technologies such as SiC and GaN. Unlike MOSFETs with a typical working frequency of around 100-300 kHz, WBG semiconductors operate at higher frequencies, with SiC reaching 500 kHz and GaN reaching 1 MHz. In such high-frequency applications involving SiC and GaN semiconductors and temperatures exceeding 150°C, C0G MLCCs often outperform film capacitors.

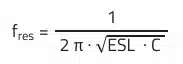

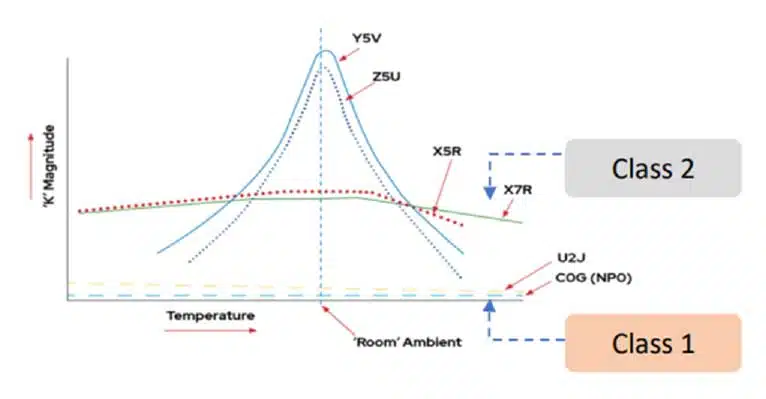

In resonant circuits, Class 1 ceramic materials like NP0 and U2J dielectrics offer the best performance compared to second-class materials like X7R. NP0 and U2J exhibit minimal capacitance variation with temperature and low dissipation factor at high frequencies (Figure 3, Equation 3). Conversely, the dissipation factor of X7R MLCCs increases steadily with frequency, leading to potential failure due to heat generation.

C0G High Voltage MLCC Solution

C0G (NP0) ceramic capacitors are perfect for applications that demand high stability and minimal losses due to their temperature coefficient of capacitance of ±30ppm/°C. They maintain their stability across a broad temperature range. The C0G high-voltage MLCC is made of Strontium Calcium Zirconium Titanate (SCZT), which has a permittivity of 20-30.

In DC-DC/OBC applications, common sizes of C0G high-voltage MLCCs include 1206, 1210, and 2220, with voltage ranges from 630 to 1000 V. These capacitors perform better at higher capacitance values.

To select the optimal capacitor, customers first calculate the total voltage and capacitance required. Engineers then determine the number of capacitors needed in series to achieve the target voltage and the number needed in parallel to increase the capacitance. To simplify the design, they choose a single type of capacitor, such as the 1210CA333J4T2A. Finally, they design and connect the capacitors to meet the desired voltage and capacitance requirements.

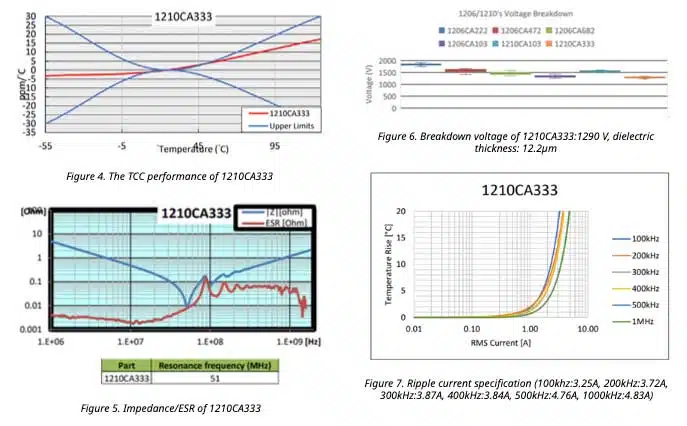

The 1210CA333J4T2A example (Figures 4-7) exemplifies the quality of KYOCERA AVX’s C0G high-voltage MLCC. In DC-DC/OBC applications, this process for selecting capacitors makes C0G high-voltage MLCC an attractive option because other resonant capacitors may necessitate the use of balance resistors, leading to increased costs and circuit complexity. Ensuring the quality and reliability of resonant capacitors is paramount to customers.

The KYOCERA AVX C0G high-voltage MLCC not only offers a suitable choice for DC-DC/OBC applications but also guarantees customers high-quality and reliable capacitors.